High-efficiency liquid homogenization device

A homogenizing device, high-efficiency technology, applied in the direction of mixers with rotating stirring devices, transportation and packaging, chemical instruments and methods, etc., can solve problems such as equipment damage, tank bottom caking, production ingredient quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below with specific embodiments, but it should be noted that the protection scope of the present invention is not limited thereto.

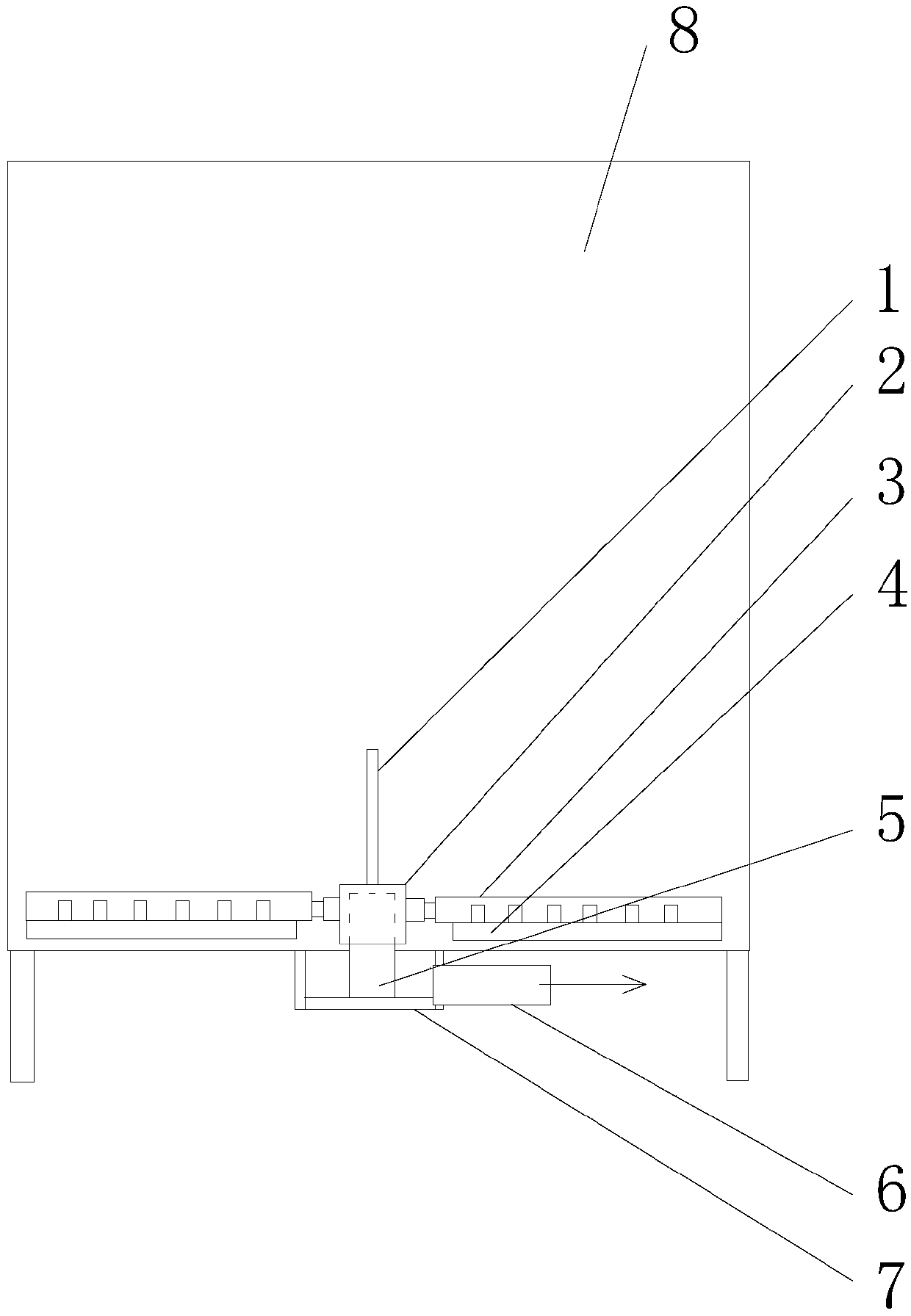

[0021] refer to figure 1 , a high-efficiency liquid homogenization device, the liquid homogenization device is installed in the storage tank 8, the liquid homogenization device includes a tank bottom sink basin 7 welded on the bottom of the storage tank 8, the outlet of the storage tank 8 6 is welded on the sink basin 7 at the bottom of the tank so that the liquid in the storage tank 8 can be taken out from the sink basin 7 at the bottom of the tank through the outlet 6, and a fixed shaft 5 is installed above the sink basin 7 at the bottom of the tank, and the A paddle assembly is rotatably installed on the fixed shaft 5; wherein, the paddle assembly includes a rotatable sleeve 2 sleeved on the fixed shaft 5, a spoiler 1 welded and fixed on the top of the sleeve 2 , the stirring pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com