Warm garment fabric

A fabric and clothing technology, applied in clothing, clothing features, clothing and other directions, can solve the problems of poor use effect, poor moisture absorption and air permeability, sultry heat, etc., and achieve the effect of meeting the needs of warmth retention and lasting function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

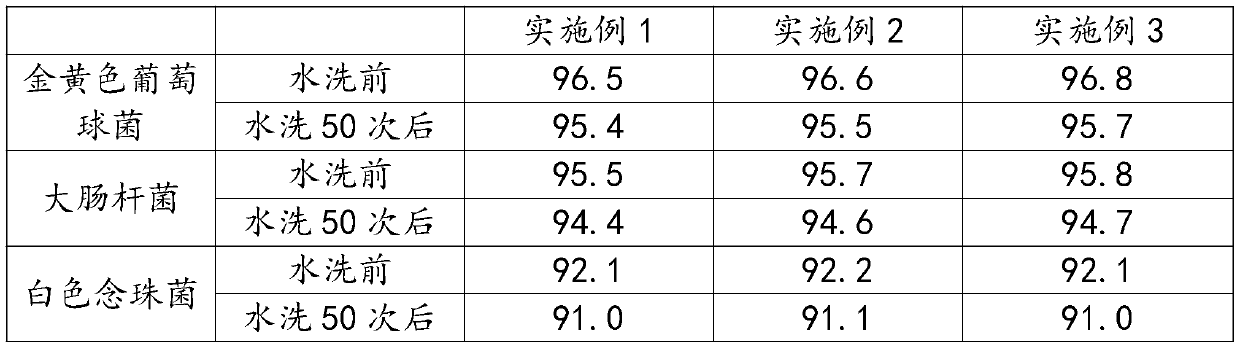

Embodiment 1

[0045] A kind of thermal clothing fabric, which is a double-sided structure fabric. The front side (i.e. the outer layer) of the fabric is cotton fabric, and the back side (i.e. the inner layer) is a heating fiber fabric with a heating effect. The front and back sides are connected by heating fibers. A heat-insulating air layer is formed between them, that is, the intermediate connection layer;

[0046] Described cotton fabric, warp yarn is the 17.15tex blended yarn that cotton linen yarn / viscose fiber is spun according to the ratio of 58 / 42, and weft yarn is pure cotton 9.68tex yarn, warp density 356 / 10cm, weft density 314 / 10cm;

[0047] For the heating fiber fabric, the warp and weft yarns all adopt 18tex heating fiber / cotton blended yarn (65 / 35), the warp density is 502 / 10cm, and the weft density is 346 / 10cm;

[0048] After the outer cotton fabric is antibacterially finished, the outer cotton fabric and the heating fiber fabric are connected through the heating fiber to pre...

Embodiment 2

[0056] A kind of thermal clothing fabric, which is a double-sided structure fabric. The front side (i.e. the outer layer) of the fabric is cotton fabric, and the back side (i.e. the inner layer) is a heating fiber fabric with a heating effect. The front and back sides are connected by heating fibers. A heat-insulating air layer is formed between them, that is, the intermediate connection layer;

[0057] Described cotton fabric, warp yarn is the 17.15tex blended yarn that cotton linen yarn / viscose fiber is spun according to the ratio of 58 / 42, and weft yarn is pure cotton 9.68tex yarn, warp density 356 / 10cm, weft density 314 / 10cm;

[0058] For the heating fiber fabric, the warp and weft yarns all adopt 18tex heating fiber / cotton blended yarn (65 / 35), the warp density is 502 / 10cm, and the weft density is 346 / 10cm;

[0059] After the outer cotton fabric is antibacterially finished, the outer cotton fabric and the heating fiber fabric are connected through the heating fiber to pre...

Embodiment 3

[0067] A kind of thermal clothing fabric, which is a double-sided structure fabric. The front side (i.e. the outer layer) of the fabric is cotton fabric, and the back side (i.e. the inner layer) is a heating fiber fabric with a heating effect. The front and back sides are connected by heating fibers. A heat-insulating air layer is formed between them, that is, the intermediate connection layer;

[0068] Described cotton fabric, warp yarn is the 17.15tex blended yarn that cotton linen yarn / viscose fiber is spun according to the ratio of 58 / 42, and weft yarn is pure cotton 9.68tex yarn, warp density 356 / 10cm, weft density 314 / 10cm;

[0069] For the heating fiber fabric, the warp and weft yarns all adopt 18tex heating fiber / cotton blended yarn (65 / 35), the warp density is 502 / 10cm, and the weft density is 346 / 10cm;

[0070] After the outer cotton fabric is antibacterially finished, the outer cotton fabric and the heating fiber fabric are connected through the heating fiber to pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com