Preparation method of RS5 wheat resistant starch

A technology of resistant starch and wheat starch, applied in the functions of food ingredients, food heat treatment, food science, etc., can solve the problems of unstable nature of natural starch, and achieve the effects of relieving diabetes, ensuring safety, and low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

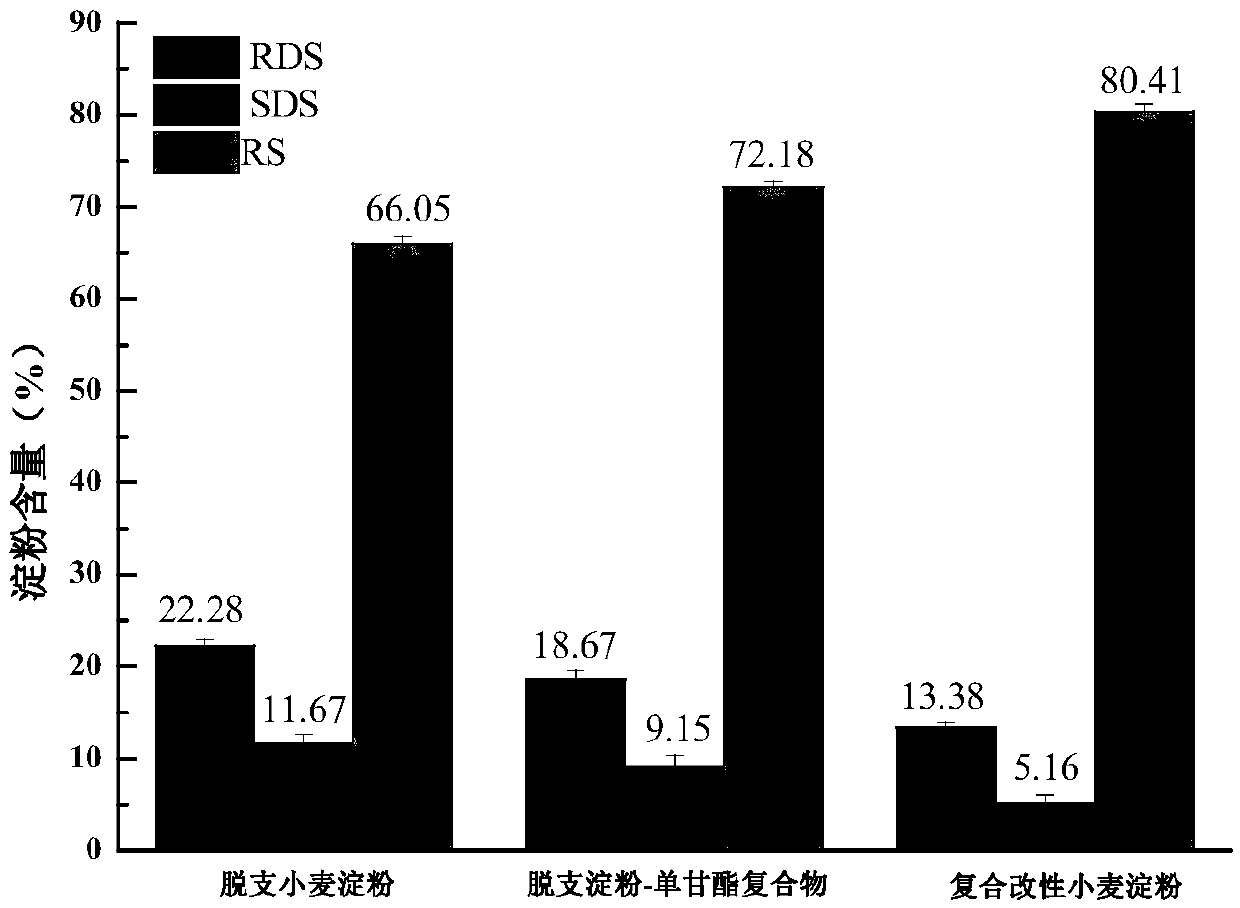

Embodiment 1

[0048] 1. First weigh 1 kg of wheat starch, add pH 5.8 phosphate buffer solution to make a 10% (w / v) starch suspension, shake it in a water bath at a temperature of 100°C for 30 minutes to obtain a starch paste, and then cool it to 58°C at room temperature , adding 40 ASPU / g pullulanase to the starch paste, and then shaking the enzymolysis in a water bath at 58°C for 9h. Immediately after the enzymatic hydrolysis, 2 times the volume of absolute ethanol was added to the starch hydrolyzate, and after stirring to inactivate the enzyme, glyceryl monostearate with a mass fraction of 1% on the dry basis of the starch was added, and stirred in a water bath at 70°C for 90 minutes. After the reaction was completed, it was rapidly cooled to room temperature (25° C.), centrifuged (3000 g, 20 min), and the precipitate was washed with 50% ethanol and dried to obtain a debranched wheat starch-glycerol monostearate complex.

[0049] 2. After the debranched wheat starch-glyceryl monostearate ...

Embodiment 2

[0052] 1. First weigh 1 kg of wheat starch, add pH 5.8 phosphate buffer solution to make a 10% (w / v) starch suspension, shake it in a water bath at a temperature of 100°C for 30 minutes to obtain a starch paste, and then cool it to 58°C at room temperature , adding 60 ASPU / g pullulanase to the starch paste, and then shaking the enzymolysis in a water bath at 58°C for 6h. Immediately after the enzymolysis, 2 times the volume of absolute ethanol was added to the starch hydrolyzate, and after stirring to inactivate the enzyme, glyceryl monostearate with a mass fraction of 2% on the dry basis of the starch was added, and stirred in a water bath at 70°C for 60 minutes. After the reaction was completed, it was rapidly cooled to room temperature (25° C.), centrifuged (3000 g, 20 min), and the precipitate was washed with 50% ethanol and dried to obtain a debranched wheat starch-glycerol monostearate complex.

[0053] 2. After the debranched wheat starch-glyceryl monostearate composite...

Embodiment 3

[0056] 1. First weigh 1 kg of wheat starch, add pH 5.8 phosphate buffer solution to make a 10% (w / v) starch suspension, shake it in a water bath at a temperature of 100°C for 30 minutes to obtain a starch paste, and then cool it to 58°C at room temperature , adding 80 ASPU / g pullulanase to the starch paste, and then shaking the enzymolysis in a water bath at 58°C for 3h. Immediately after the enzymatic hydrolysis, 2 times the volume of absolute ethanol was added to the starch hydrolyzate, and after stirring to inactivate the enzyme, glyceryl monostearate with a mass fraction of 3% on a dry basis of starch was added, and stirred in a water bath at 70°C for 30 minutes. After the reaction was completed, it was rapidly cooled to room temperature (25° C.), centrifuged (3000 g, 20 min), and the precipitate was washed with 50% ethanol and dried to obtain a debranched wheat starch-glycerol monostearate complex.

[0057] 2. After the debranched wheat starch-glyceryl monostearate compou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com