A resistive random access memory

A technology of resistive memory and resistive layer, applied in electrical components and other directions, can solve the problems of increasing device storage speed, low setting speed, and reducing resistance state retention characteristics and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

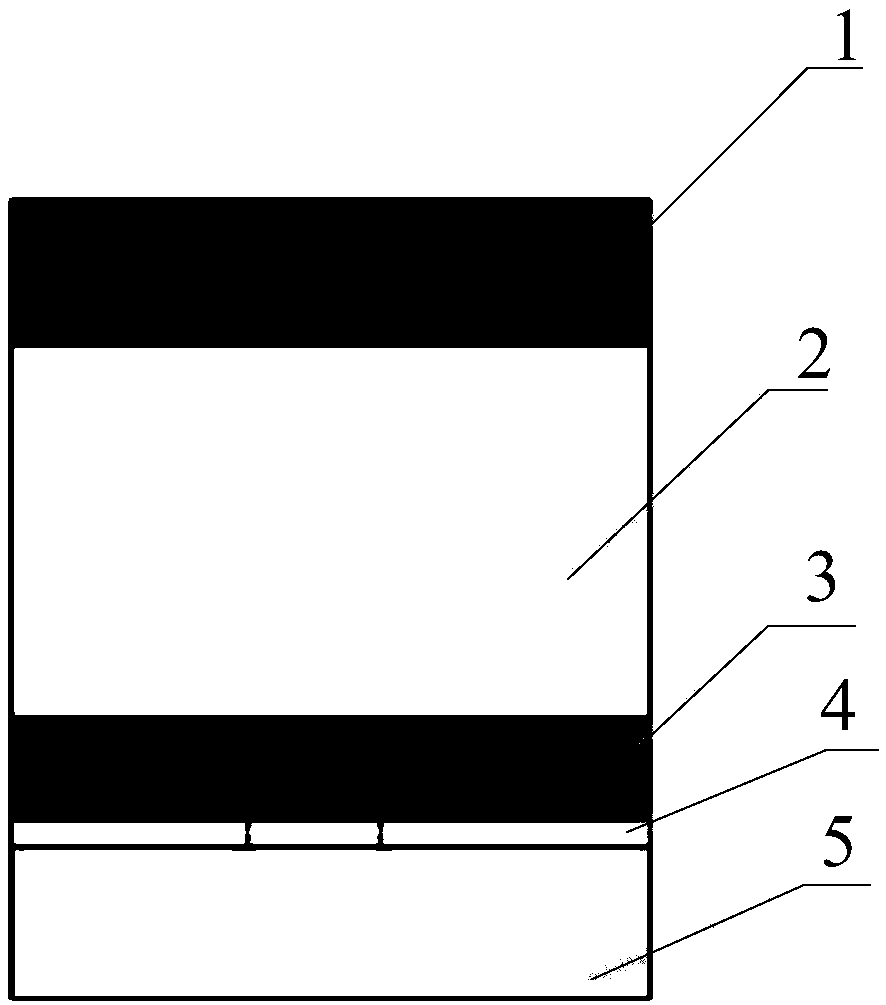

[0022] In order to improve the resistive performance of the resistive variable memory, an embodiment of the present invention provides a resistive variable memory, which includes: a first electrode layer; a resistive variable layer located below the first electrode layer; a first an intermediate layer located below the resistive layer, and the mobility of the first intermediate layer is less than 1 cm 2 / Vs; the second intermediate layer is located below the first intermediate layer, and the material of the second intermediate layer includes a two-dimensional material; the second electrode layer is located below the second intermediate layer.

[0023] The technical solution of the present invention will be further described in detail below with reference to the drawings and specific embodiments.

[0024] In order to fully understand the technical solution of this article, this article first introduces the resistive variable memory. The resistive variable memory switches the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com