A plugging and sealing device with crack guiding function during static crushing

A technology of static crushing and sealing device, applied in blasting and other directions, can solve the problem of high control cost, achieve the effect of saving drilling cost, simple assembly and expanding hole spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

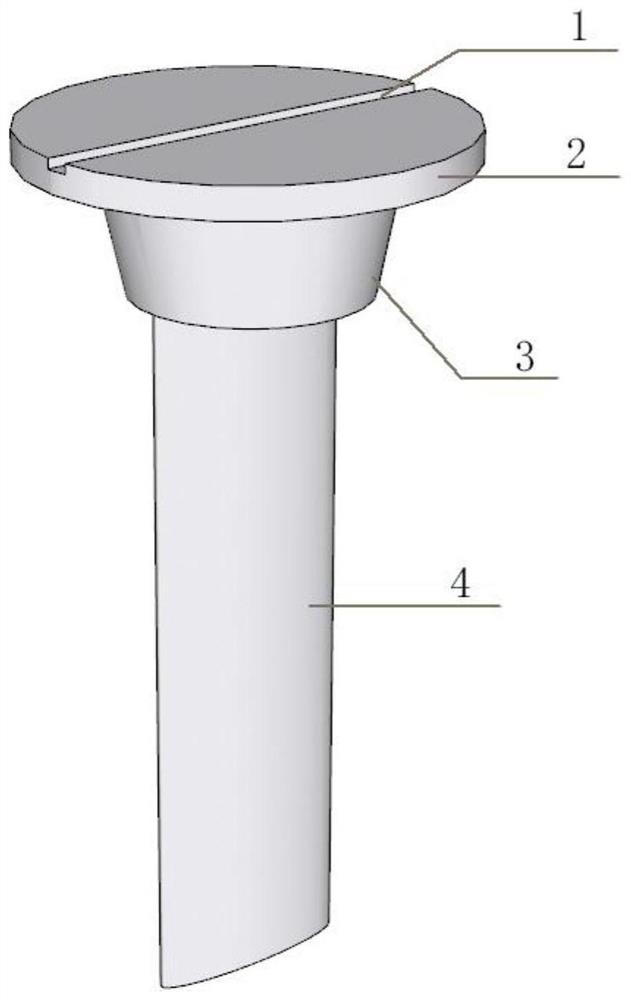

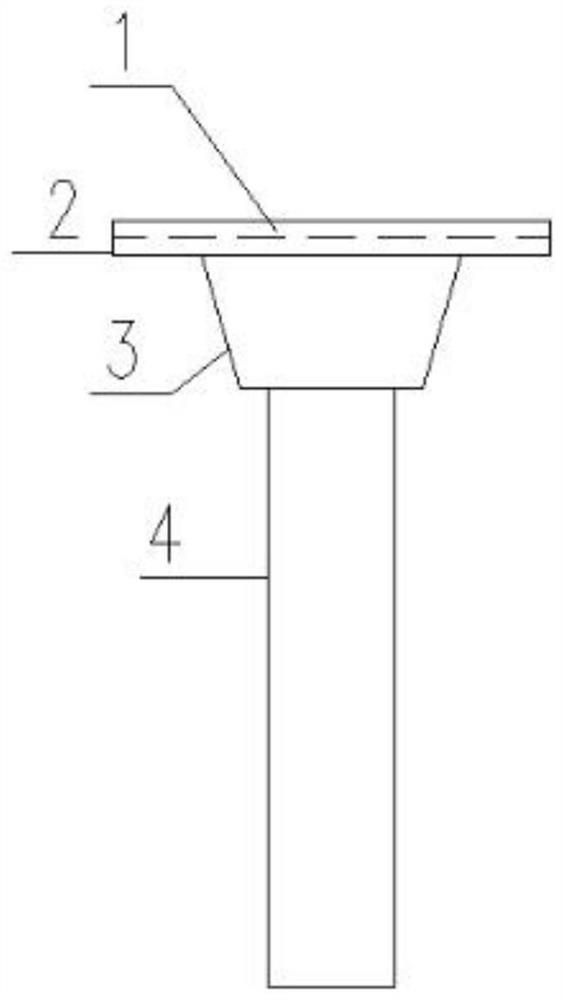

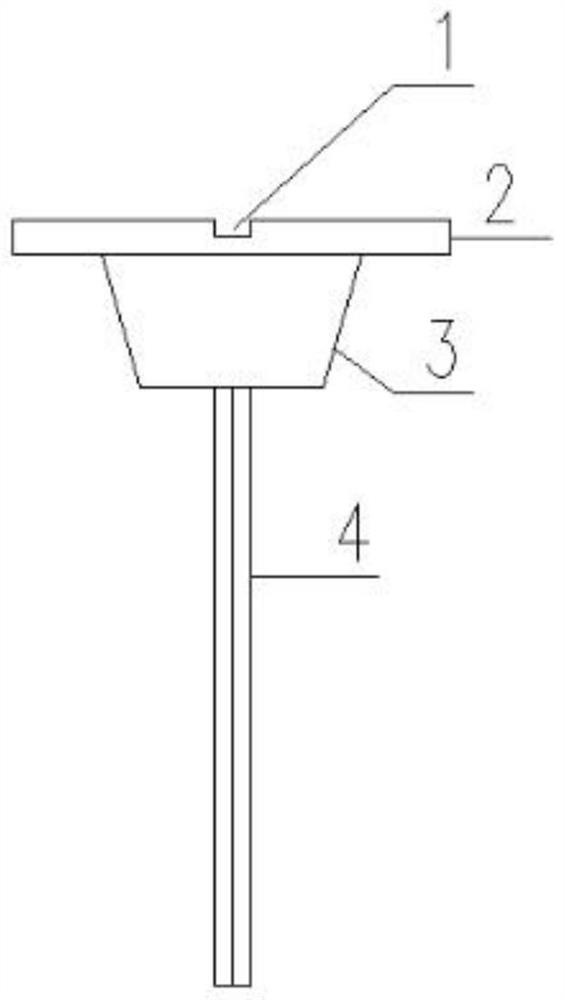

[0015] Specific Embodiment 1: This embodiment is a plugging and sealing device with crack guiding function in the static crushing process, which includes a plugging member and a fixing member; The hole part and the crack guide part; the direction indicating part is composed of a groove 1 and a round steel sheet 2, the closed plugging part is a short steel column 3, and the crack guide part is an arc-shaped steel plate 4; the fixing The component is composed of a top steel plate 5, a nut 6, a screw rod 7 and a bottom steel plate 8; the top steel plate 5 and the bottom steel plate 8 are arranged in parallel and symmetrically, and the four corners of the top steel plate 5 and the bottom steel plate 8 are provided with holes, and the top steel plate 5 and the bottom The four corners of the steel plate 8 are respectively connected and fixed by the screw rod 7, and the two ends of the screw rod 7 are locked by the nut 6; the short steel column 3 is arranged on the upper end of the cu...

specific Embodiment approach 2

[0017] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the use method of the plugging and sealing device with crack guiding function in the static crushing process is specifically carried out according to the following steps: first drill the blast hole on the concrete member 9, Stir the static breaking agent evenly and fill it into the blast hole, then insert the plugging member into the blast hole, the short steel column 3 seals the blast hole tightly, and then rotate the round steel sheet 2 to ensure that the direction of the groove 1 is in line with the expected cracking The direction is the same, and finally the top steel plate 5 is placed on the upper surface of the sealing member, the bottom steel plate 8 is placed on the lower surface of the concrete member 9, and the four corners of the top steel plate 5 and the bottom steel plate 8 are respectively connected and fixed by the screw rod 7, and the The two ends are locked by...

specific Embodiment approach 3

[0019] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the short steel column 3 is a rounded truss structure. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com