Aluminum alloy inner container for ultra-large high-pressure air bottle and manufacturing method thereof

A high-pressure gas cylinder and super-sized technology, which is applied to the aluminum alloy liner for super-large high-pressure gas cylinders and its manufacturing field, can solve the problems of small volume, heavy quality, and poor reliability of high-pressure gas cylinders, and achieve convenient operation and low pollution , The effect of less loss of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

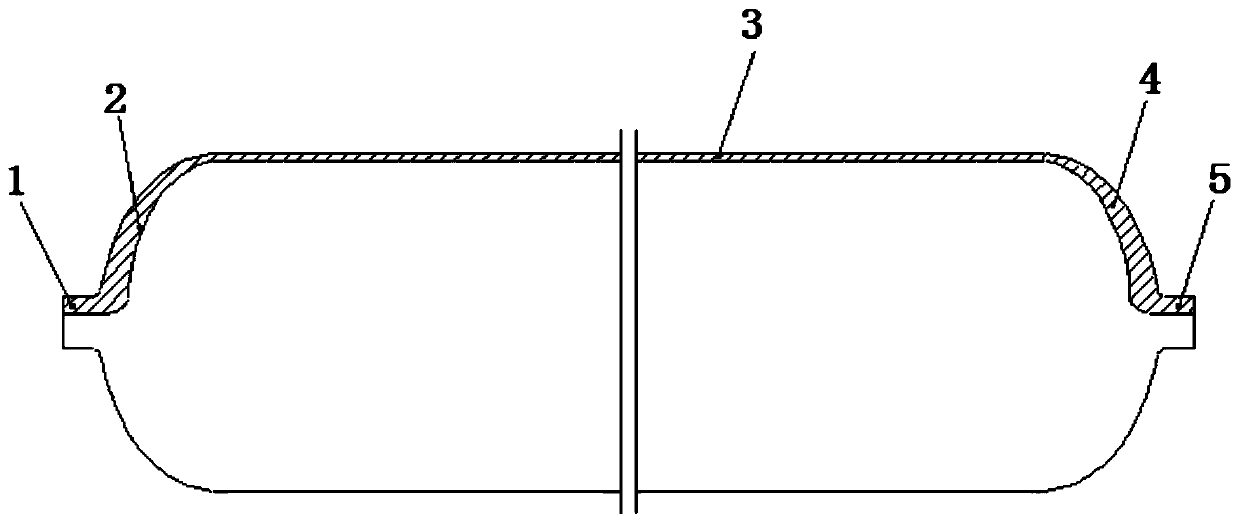

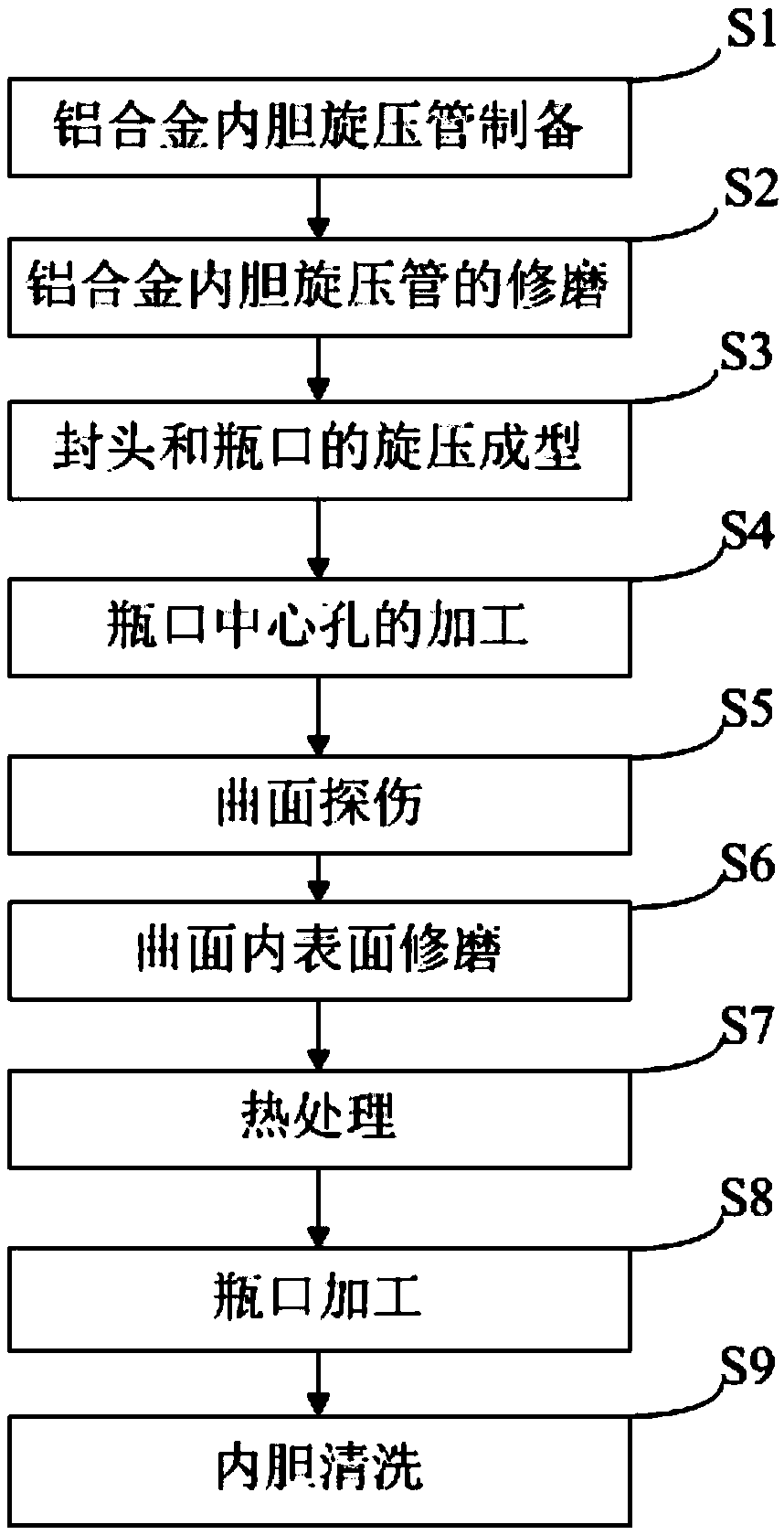

[0115] Prepare an aluminum alloy inner liner for super-sized high-pressure gas cylinders with a diameter of 300mm, a length of 10m, and a wall thickness of 6mm. The rated pressure of the high-pressure gas cylinder is 25Mpa, which specifically includes the following steps:

[0116] S1, the aluminum alloy inner liner spinning tube is prepared, the straight tube section 3 of the seamless pipe is subjected to multi-pass powerful external spinning forming processing using the ultra-long cylinder tension spinning equipment to obtain the aluminum alloy inner liner spinning tube; this step Specifically include the following steps:

[0117] S1a, the spinning forming of the straight section 3 of the aluminum alloy inner liner spinning tube, the ultra-long cylinder tension spinning equipment is used to spin a seamless pipe with a length of 1600mm for 4 times using a tension spinning device with a three-wheel offset positive spinning method. During the pressing process, the offset amount in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com