A flexible wheel cup body of harmonic reducer based on continuous transition curve

A transition curve, flexible wheel cup technology, applied in the direction of components with teeth, belt/chain/gear, winch, etc., can solve the problem of reducing the service life of the harmonic reducer, improve the weak link, improve the use Strength, the effect of reducing stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

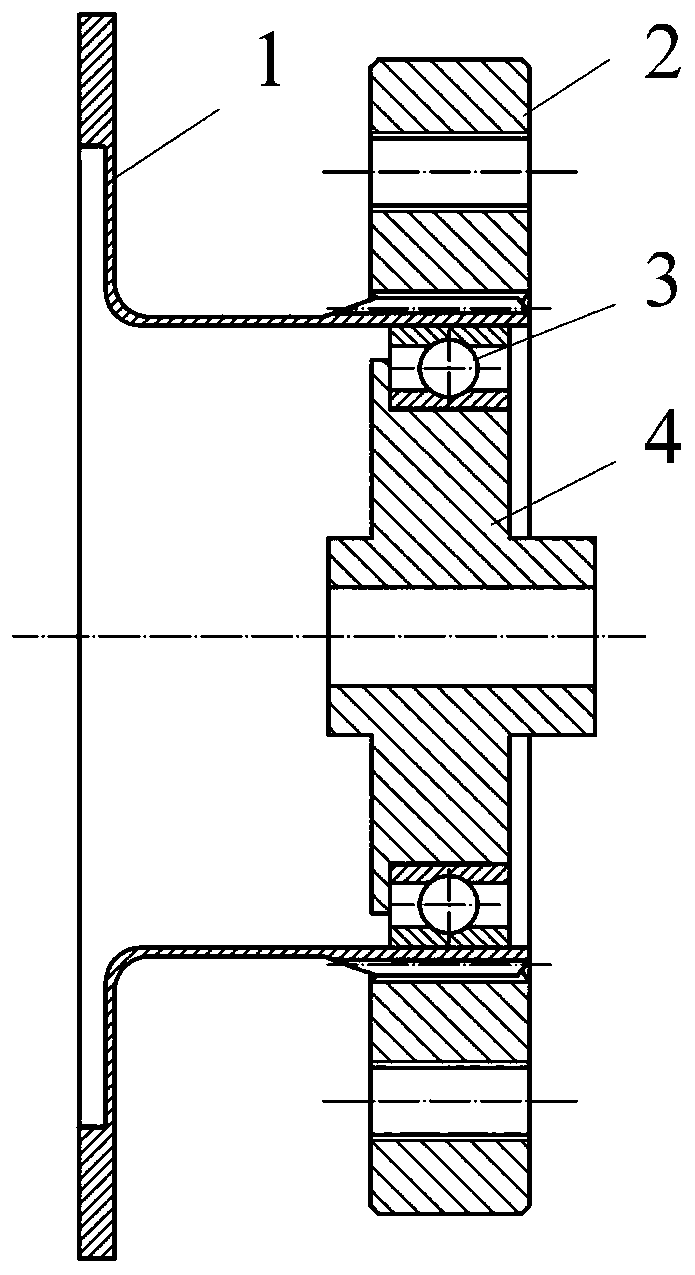

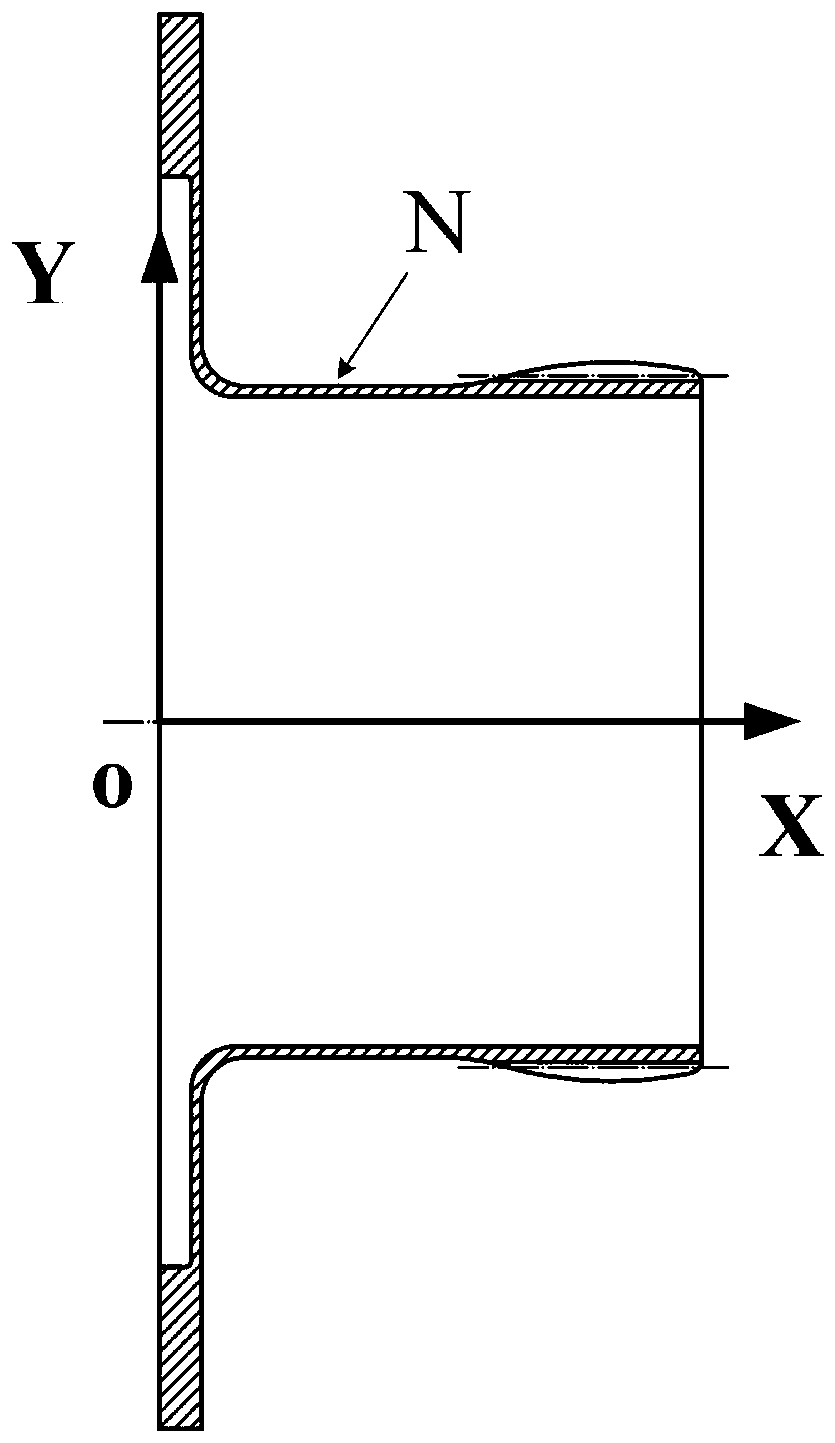

[0049] Refer to attached image 3 , to establish the Cartesian coordinate system shown, which is used to represent the coordinate position of the flexspline outer contour curve N.

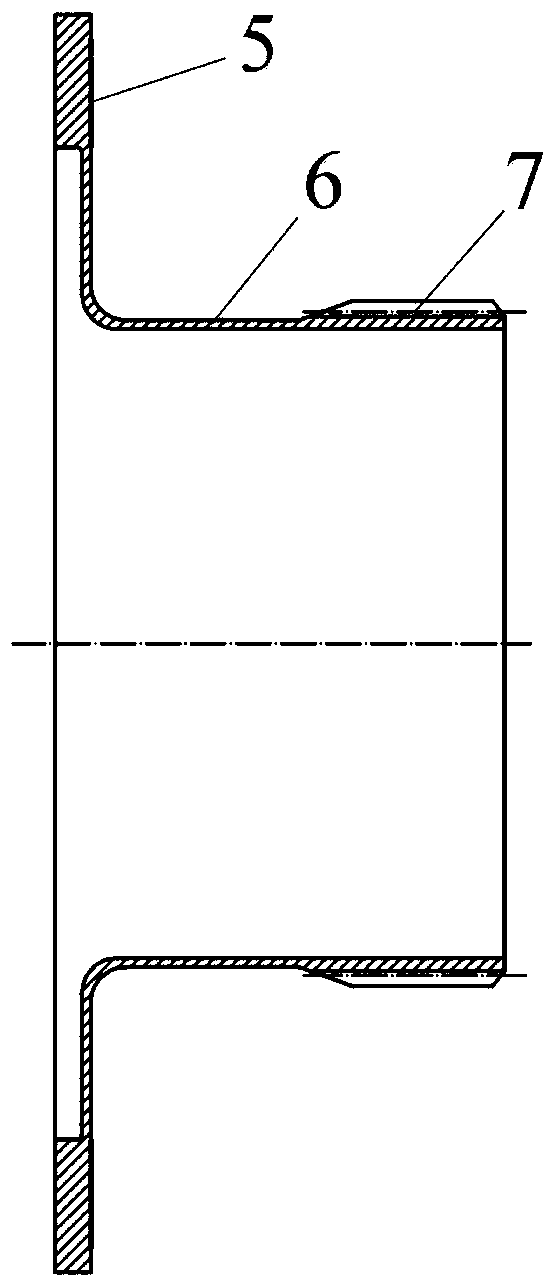

[0050] Refer to attached Figure 4 , the shape curve N of the outer contour structure of the cup includes the transition curve section AB between the cup bottom flange and the cup body, the straight line section BC of the cup body, the transition curve section CD between the cup body and the ring gear, the curve section DE of the ring gear, and the curve section between the ring gear and the ring gear. The structural feature of the transition curve section EF of the cup mouth is defined by the method described by the curve equation under the Cartesian coordinate system. The Cartesian coordinate system takes the central axis of the cup body as the abscissa axis and the cup bottom flange as the ordinate axis.

[0051] The transition curve section AB between the cup bottom flange and the cup body.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com