Cylindrical sewer cleaning and maintenance robot

A sewer and robot technology, applied in the field of robots, can solve the problems of low cleaning efficiency, achieve efficient cleaning and maintenance, and improve the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

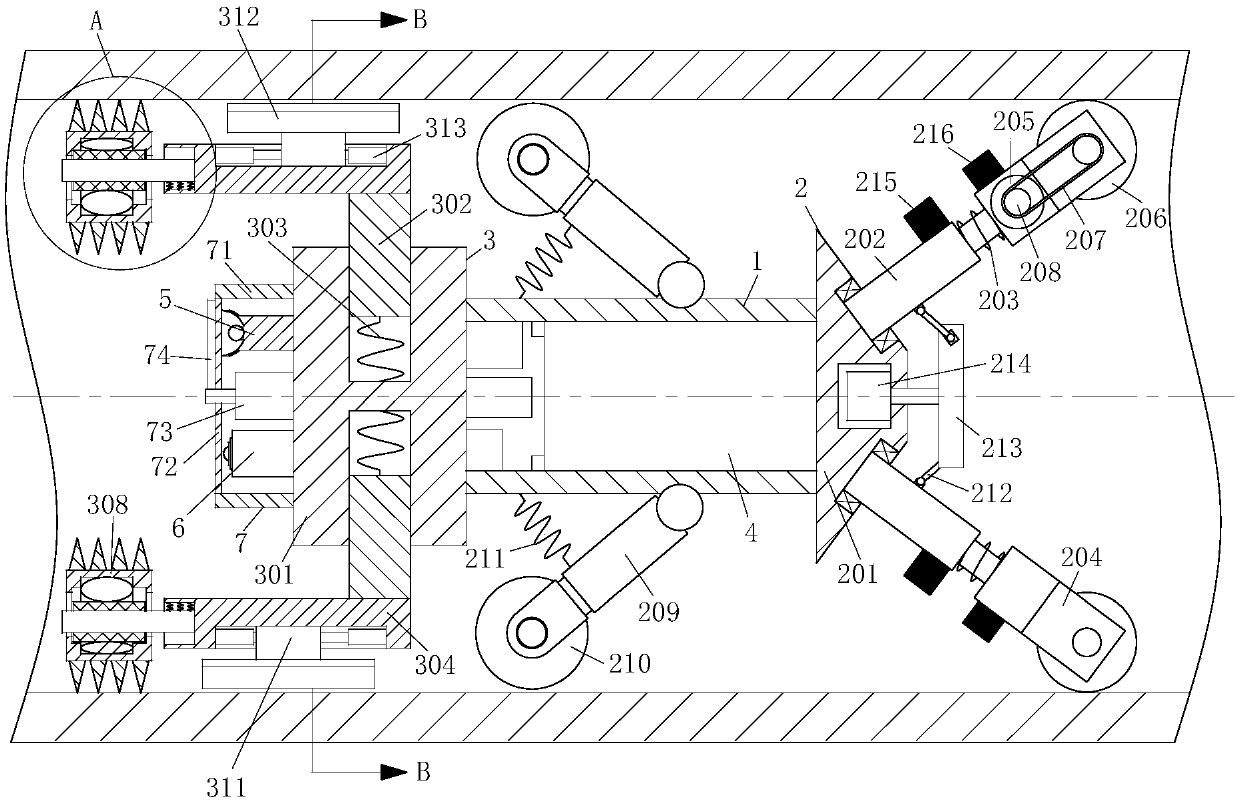

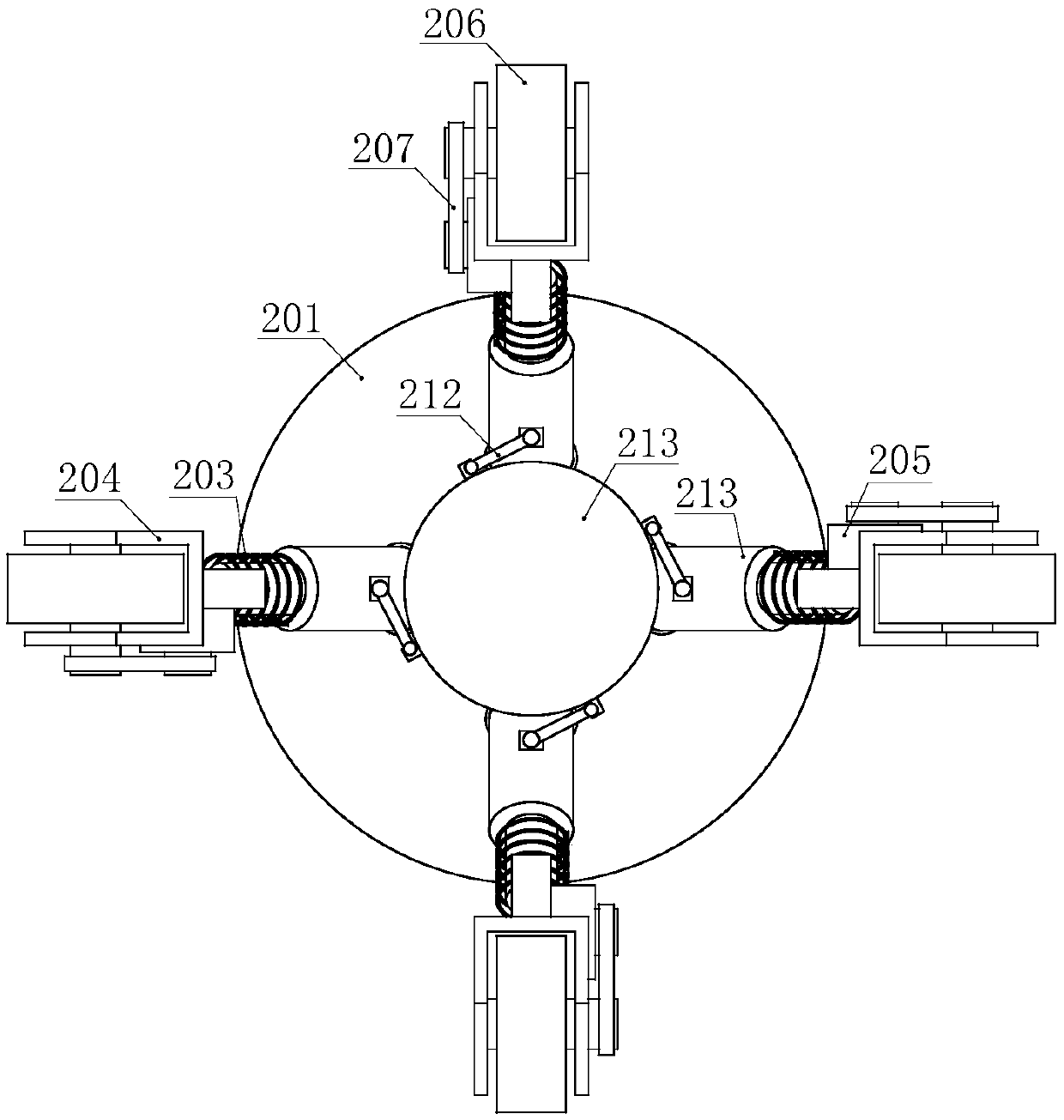

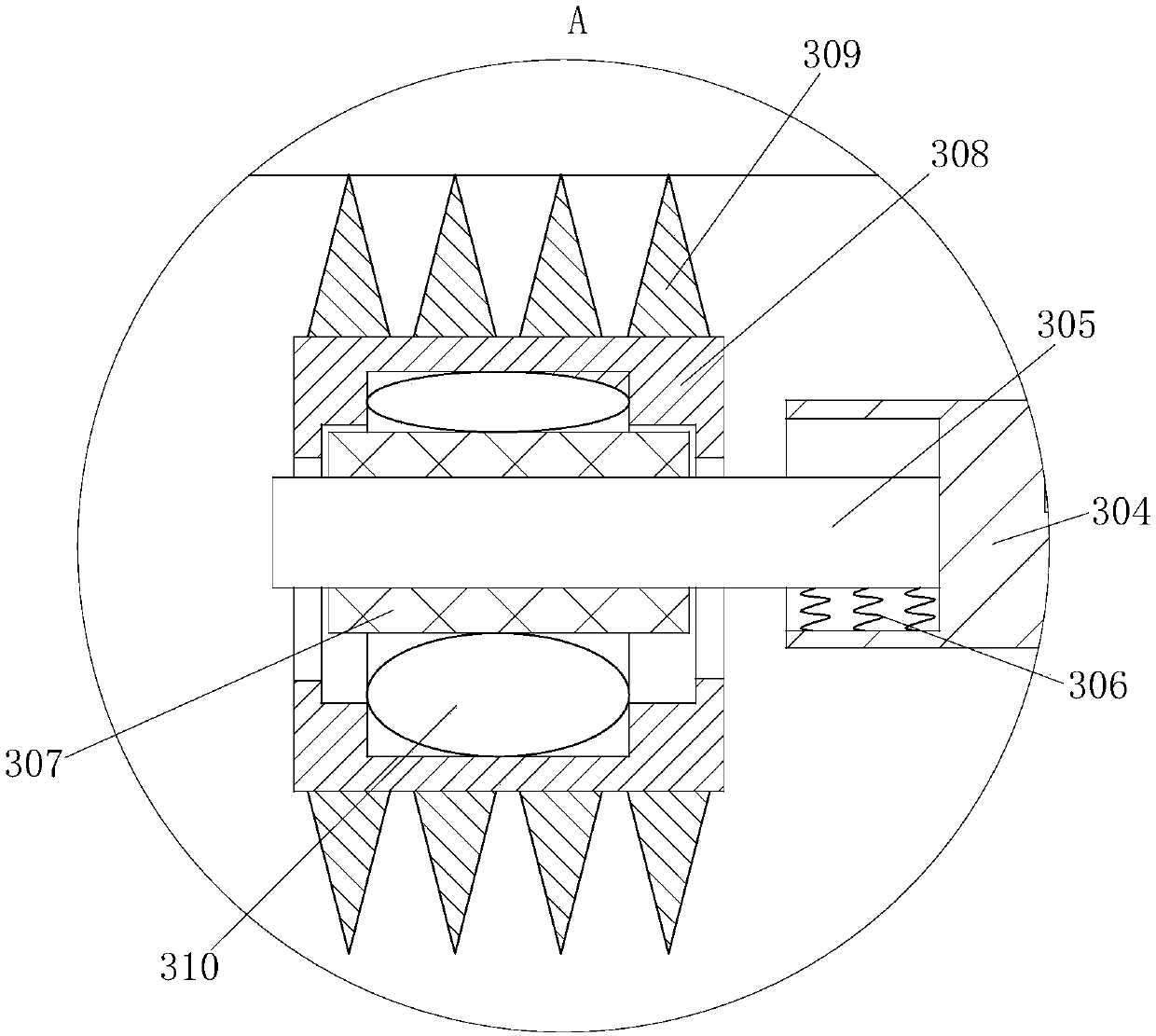

[0030] As an embodiment of the present invention, a No. 1 chute is provided on the left side of the scraper 304, and a slide bar 305 is slidably connected in the No. 1 chute; On the No. chute, the sliding rod 305 is sleeved with a bearing 307; the bearing 307 is sleeved with a rolling barrel 308; the rolling barrel 308 is provided with a helical blade 309, which is used to cut off the inner wall of the water pipe The sundries on the top, through the cooperation of the helical blade 309, rolling barrel 308, bearing 307, slide bar 305 and No. 4 spring 306, make the helical blade 309 contact with the pipe wall of the sewer under the promotion of No. 4 spring 306 all the time. When the scraper 304 rotates on the inner wall of the sewer, the rolling barrel 308 will drive the helical blade 309 to roll on the sewer wall. The case where the plate 304 is difficult to scrape off.

[0031] As an embodiment of the present invention, a protective device 7 is provided on the left side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com