PCB (printed circuit board) ultrasonic hydrocarbon cleaner and application method thereof

A hydrocarbon cleaning agent and PCB board technology, applied in the field of cleaning agents, can solve problems such as difficult to clean, waste water discharge, non-conforming to environmental protection, etc., and achieve the effect of sufficient cleaning and accelerated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

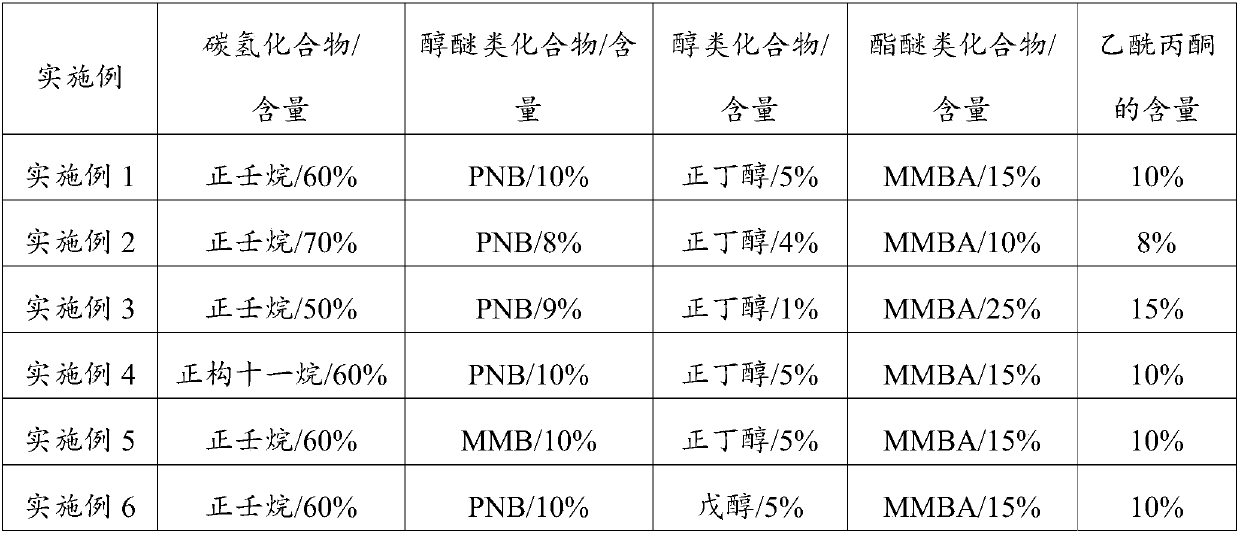

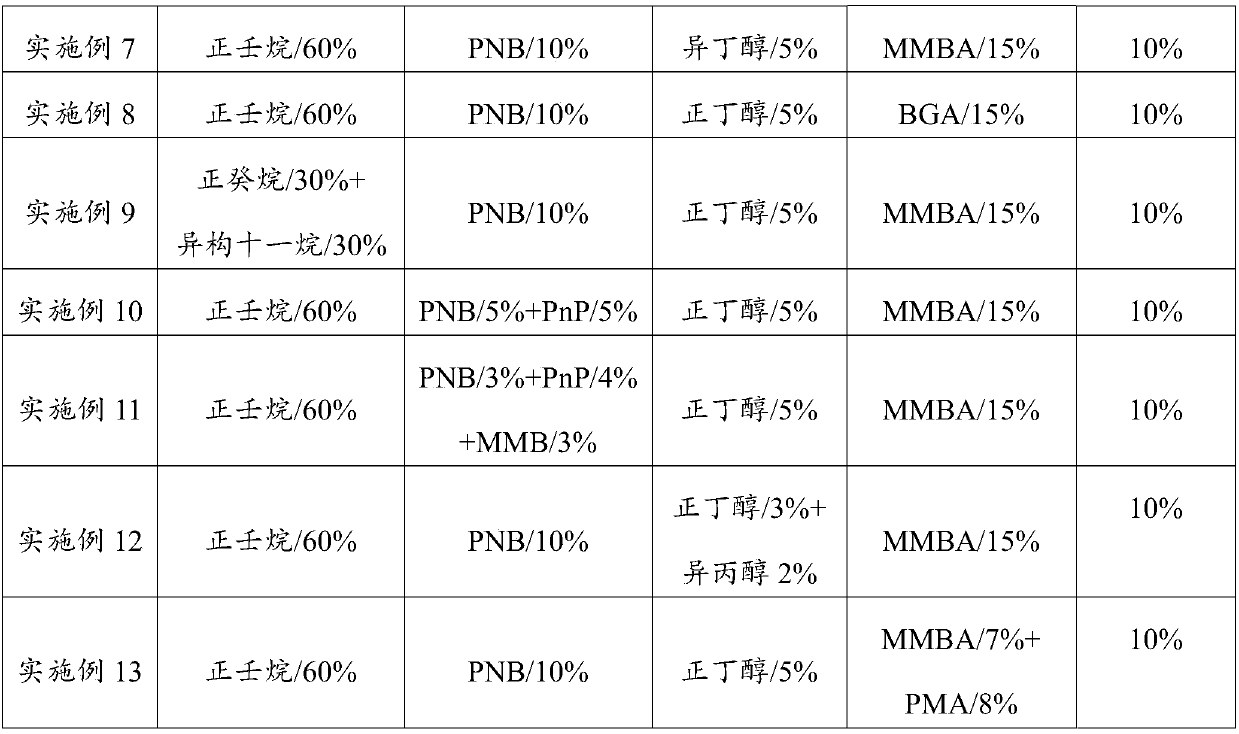

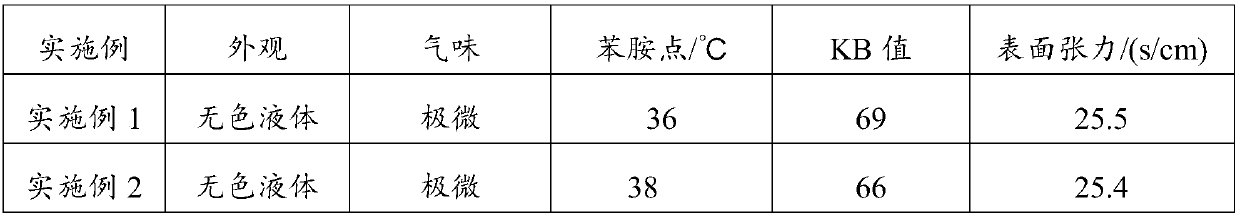

Examples

Embodiment 1

[0024] A PCB board ultrasonic hydrocarbon cleaning agent comprises the following components by weight percentage:

[0025] Hydrocarbons 60%;

[0026] Alcohol ether compounds 10%;

[0027] Alcohol compounds 5%;

[0028] Ester ether compounds 15%;

[0029] Acetylacetone 10%.

[0030] Among them, the hydrocarbon is n-nonane, the alcohol ether compound is PNB, the alcohol compound is n-butanol, and the ester ether compound is MMBA.

[0031] Thoroughly mix the above components to obtain PCB board ultrasonic hydrocarbon cleaning agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com