Anti-sliding coating

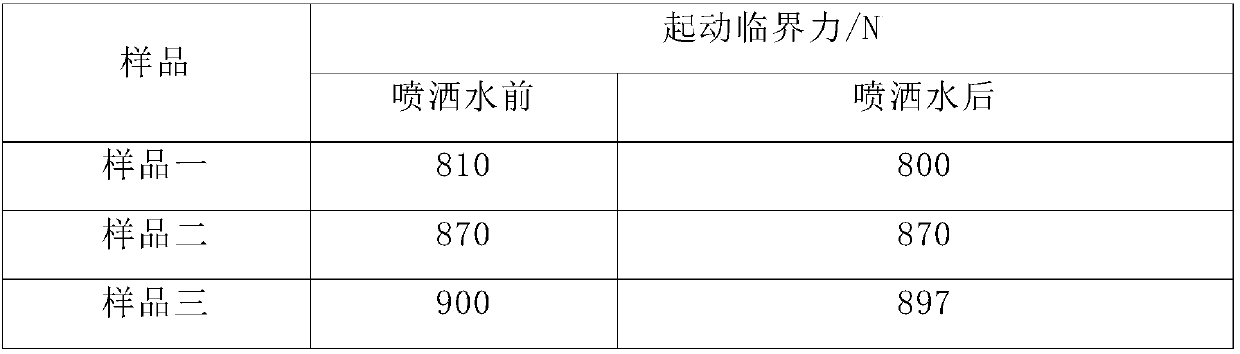

A technology for anti-slip coatings and raw materials, applied in the field of coatings, can solve the problems of reduced anti-slip effect and easy surface slippage, etc., and achieve the effect of improving anti-slip performance, good dry and wet anti-skid, and good wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The anti-slip coating is composed of the following raw material components in the weight ratio:

[0029] 4 parts of triethanolamine; 10 parts of magnesium hydroxide; 1 part of dihydroxymethylpropionic acid; 6 parts of polyglutamic acid; 3 parts of liquid paraffin; 1 part of aristolochic acid; 8 parts of abietic acid; 3 parts of carbon black; silicon 10 parts of acrylic emulsion; 10 parts of polyurethane emulsion; 44 parts of distilled water.

[0030] The particle size of the magnesium hydroxide is 10-20 microns; the number average molecular weight of the polyglutamic acid is 50,000-100,000; the particle size of the carbon black is 10-30 nanometers; the solid content of the silicon acrylic emulsion is 40%; the solid content of the polyurethane emulsion is 40%.

[0031] The preparation method of this antiskid coating comprises the following steps successively:

[0032] (1) get each raw material component by described weight ratio;

[0033] (2) Add magnesium hydroxide a...

Embodiment 2

[0039] The anti-slip coating is composed of the following raw material components in the weight ratio:

[0040] 6 parts of triethanolamine; 16 parts of magnesium hydroxide; 3 parts of dihydroxymethylpropionic acid; 8 parts of polyglutamic acid; 5 parts of liquid paraffin; 3 parts of aristolochic acid; 10 parts of abietic acid; 5 parts of carbon black; silicon 12 parts of acrylic emulsion; 12 parts of polyurethane emulsion; 20 parts of distilled water.

[0041] The particle size of the magnesium hydroxide is 20-30 microns; the number average molecular weight of the polyglutamic acid is 100,000-150,000; the particle size of the carbon black is 30-50 nanometers; the solid content of the silicon acrylic emulsion is 60%; the solid content of the polyurethane emulsion is 60%.

[0042] The preparation method of this antiskid coating comprises the following steps successively:

[0043] (1) get each raw material component by described weight ratio;

[0044] (2) Add magnesium hydroxi...

Embodiment 3

[0050] The anti-slip coating is composed of the following raw material components in the weight ratio:

[0051] 5 parts of triethanolamine; 13 parts of magnesium hydroxide; 2 parts of dihydroxymethylpropionic acid; 7 parts of polyglutamic acid; 4 parts of liquid paraffin; 2 parts of aristolochic acid; 9 parts of abietic acid; 4 parts of carbon black; silicon 11 parts of acrylic emulsion; 11 parts of polyurethane emulsion; 32 parts of distilled water.

[0052] The particle size of the magnesium hydroxide is 15-25 microns; the number average molecular weight of the polyglutamic acid is 75000-125000; the particle size of the carbon black is 25-40 nanometers; the solid content of the silicon-acrylic emulsion is 50%; the solid content of the polyurethane emulsion is 50%.

[0053] The preparation method of this antiskid coating comprises the following steps successively:

[0054] (1) get each raw material component by described weight ratio;

[0055] (2) Add magnesium hydroxide a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com