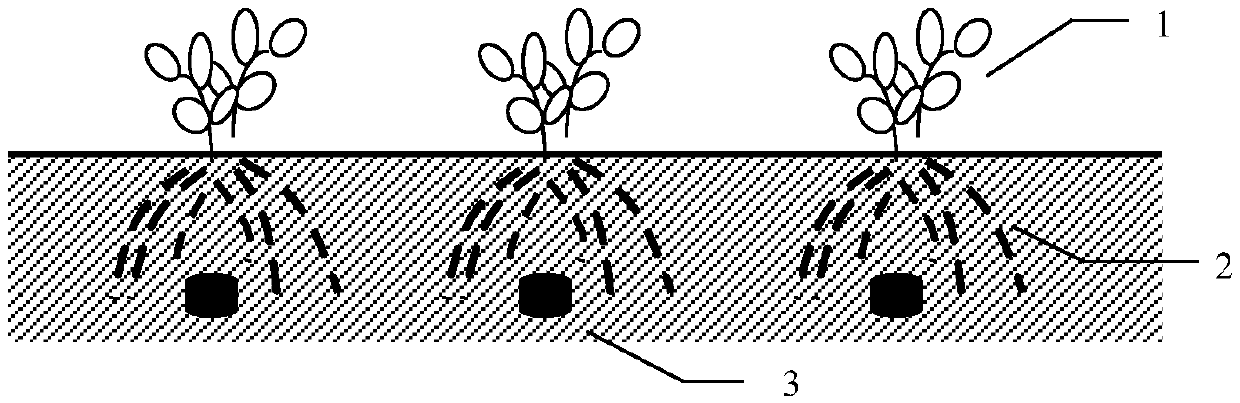

Production method and large-scale application of special organic block-type fertilizer for peanuts

A technology of organic blocks and organic materials, applied in the direction of organic fertilizers, inorganic fertilizers, applications, etc., can solve the problems of easy leaching of nutrients and low organic matter content, and achieve the effect of reducing the amount of chemical fertilizer application and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

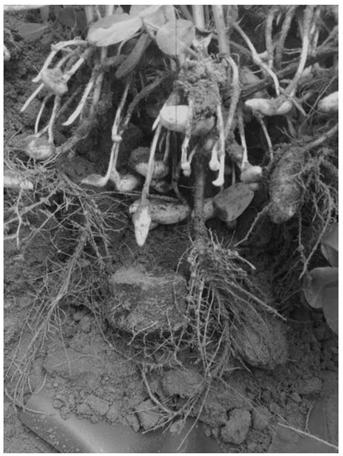

[0026] The decomposed stalks are dried in the air, and the water content is reduced to below 15%, and then pulverized, and the particle size is ≤3mm. According to the weight ratio, take 400kg of straw, 15kg of lime nitrogen powder, 8kg of diammonium phosphate powder, 6kg of potassium sulfate powder, 0.5kg of ammonium molybdate powder, 0.2kg of borax powder, 0.5kg of copper sulfate powder, 0.5kg of zinc powder, 0.5kg of magnesium sulfate powder, 0.5kg of manganese sulfate powder, 0.3kg of ferrous sulfate powder and other components are uniformly mixed, and put into the mold according to the weight of each piece of fertilizer 40 grams. The briquetting machine is extruded to form a cylindrical block fertilizer, with a size of 5 cm in diameter and a height of 3 cm. According to the peanut variety, the number of plants planted in previous years, the spacing between plants, the row spacing and the yield, calculate the amount of special organic block fertilizer for peanuts per unit a...

Embodiment 2

[0028] The decomposed straw and peat are mixed in the air, and the water content is reduced to below 15%, and then crushed, and the particle size is ≤3mm. According to the weight ratio, take 450kg of straw, 12kg of lime nitrogen powder, 6kg of diammonium phosphate powder, 5kg of potassium sulfate powder, 0.5kg of ammonium molybdate powder, 0.2kg of borax powder, 0.5kg of copper sulfate powder, 0.5kg of zinc powder, 0.5kg of magnesium sulfate powder, 0.5kg of manganese sulfate powder, 0.3kg of ferrous sulfate powder and other components are uniformly mixed, and put into the mold according to the weight of each piece of fertilizer 30 grams. The briquetting machine is extruded to make a cuboid block fertilizer, the size of which is 3 cm in diameter and 2 cm high. According to the peanut variety, the number of plants planted in previous years, the spacing between plants, the row spacing and the yield, calculate the amount of special organic block fertilizer for peanuts per unit ar...

Embodiment 3

[0030] The decomposed straw and chicken manure are mixed in the air, and the water content is reduced to below 15%, and then crushed, and the particle size is ≤3mm. According to weight ratio, take straw 350kg, and lime nitrogen powder 18kg, diammonium phosphate powder 10kg, potassium sulfate powder 7kg, ammonium molybdate powder 0.5kg, borax powder 0.2kg, copper sulfate powder 0.5kg, sulfuric acid 0.5kg of zinc powder, 0.5kg of magnesium sulfate powder, 0.5kg of manganese sulfate powder, 0.3kg of ferrous sulfate powder and other components are uniformly mixed, and then put into the mold according to the weight of each piece of fertilizer 50 grams. The briquetting machine is extruded to form a cylinder-shaped block fertilizer with a size of 3 cm in diameter and 4 cm in height. According to the peanut variety, the number of plants planted in previous years, the spacing between plants, the row spacing and the yield, calculate the amount of special organic block fertilizer for pea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com