A kind of preparation technology of environment-friendly and durable building material

A technology for building materials and preparation processes, applied in the field of building materials, can solve problems such as insufficient impermeability and frost resistance of building materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] An environmentally friendly and durable building material proposed by the present invention comprises the following raw materials in parts by weight: 100 parts of Portland cement, 30 parts of pozzolan, 300 parts of sand, 5 parts of aggregate, 10 parts of antifreeze, 15 parts of xanthan gum, 2 parts of water reducer, 30 parts of water;

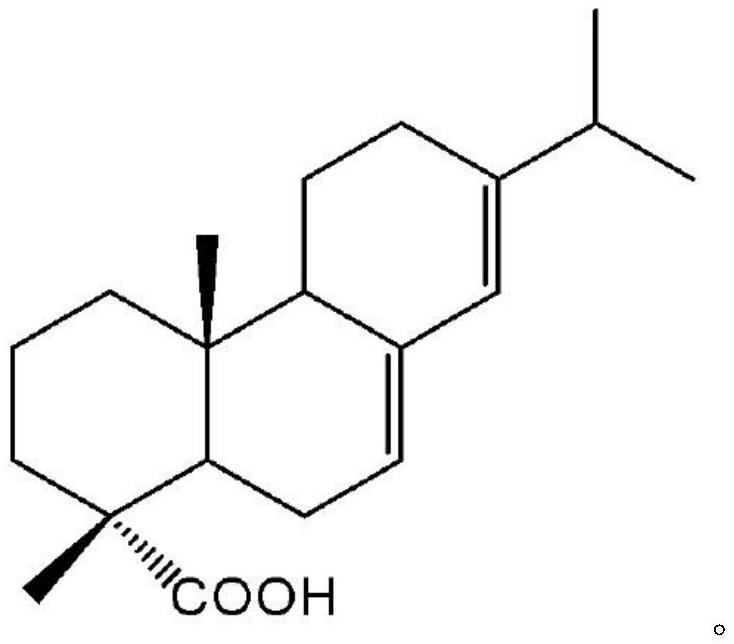

[0027] Described antifreeze is made of antifreeze component A and sodium nitrite, wherein, the mass ratio of antifreeze component A and sodium nitrite in antifreeze is 1:3, and the structural formula of antifreeze component A is as follows:

[0028]

[0029] The mass ratio of the volcanic ash to the xanthan gum is 2:1.

[0030] Its preparation process comprises the following steps:

[0031] S1. Preparation of antifreeze: mix antifreeze component A and sodium nitrite in proportion, and mechanically stir until uniform to obtain antifreeze;

[0032] S2. Prepare raw materials: Weigh each raw material according to 100 parts of Portland c...

Embodiment 2

[0035] An environmentally friendly and durable building material proposed by the present invention comprises the following raw materials in parts by weight: 100 parts of Portland cement, 36 parts of pozzolan, 350 parts of sand, 8 parts of aggregate, 13 parts of antifreeze, 18 parts of xanthan gum, 3 parts of water reducer, 40 parts of water;

[0036] Described antifreeze is made of antifreeze component A and sodium nitrite, wherein, the mass ratio of antifreeze component A and sodium nitrite in antifreeze is 1:3, and the structural formula of antifreeze component A is as follows:

[0037]

[0038] The mass ratio of the volcanic ash to the xanthan gum is 2:1.

[0039] Its preparation process comprises the following steps:

[0040] S1. Preparation of antifreeze: mix antifreeze component A and sodium nitrite in proportion, and mechanically stir until uniform to obtain antifreeze;

[0041]S2. Prepare raw materials: Weigh each raw material according to 100 parts of Portland ce...

Embodiment 3

[0044] An environmentally friendly and durable building material proposed by the present invention includes the following raw materials in parts by weight: 100 parts of Portland cement, 40 parts of pozzolan, 400 parts of sand, 10 parts of aggregate, 15 parts of antifreeze, 20 parts of xanthan gum, 4 parts of water reducer, 50 parts of water;

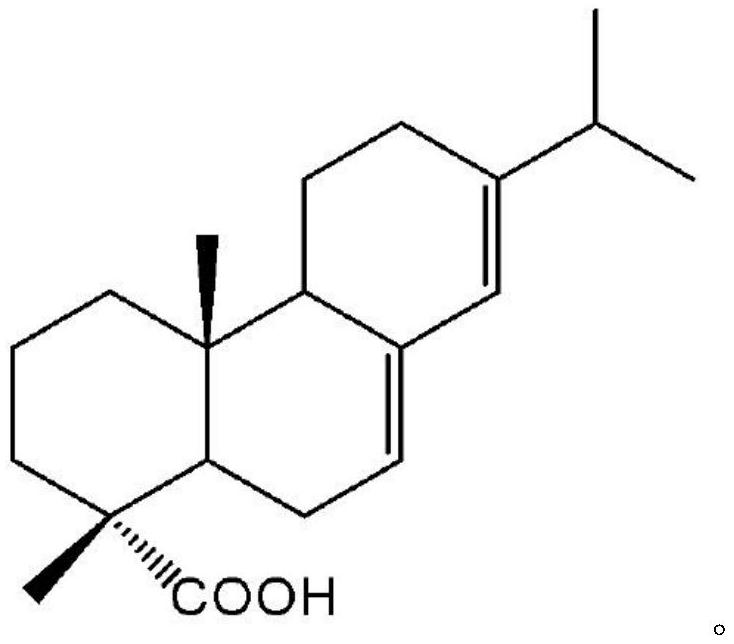

[0045] Described antifreeze is made of antifreeze component A and sodium nitrite, wherein, the mass ratio of antifreeze component A and sodium nitrite in antifreeze is 1:3, and the structural formula of antifreeze component A is as follows:

[0046]

[0047] The mass ratio of the volcanic ash to the xanthan gum is 2:1.

[0048] Its preparation process comprises the following steps:

[0049] S1. Preparation of antifreeze: mix antifreeze component A and sodium nitrite in proportion, and mechanically stir until uniform to obtain antifreeze;

[0050] S2. Prepare raw materials: Weigh each raw material according to 100 parts of Portland c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com