A printing dryer for improving drying effect

A drying machine and printing technology, applied in printing machines, printing, printing devices, etc., can solve the problems of ignoring the drying effect and insufficient drying of fabrics, and achieve the effect of improving the drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

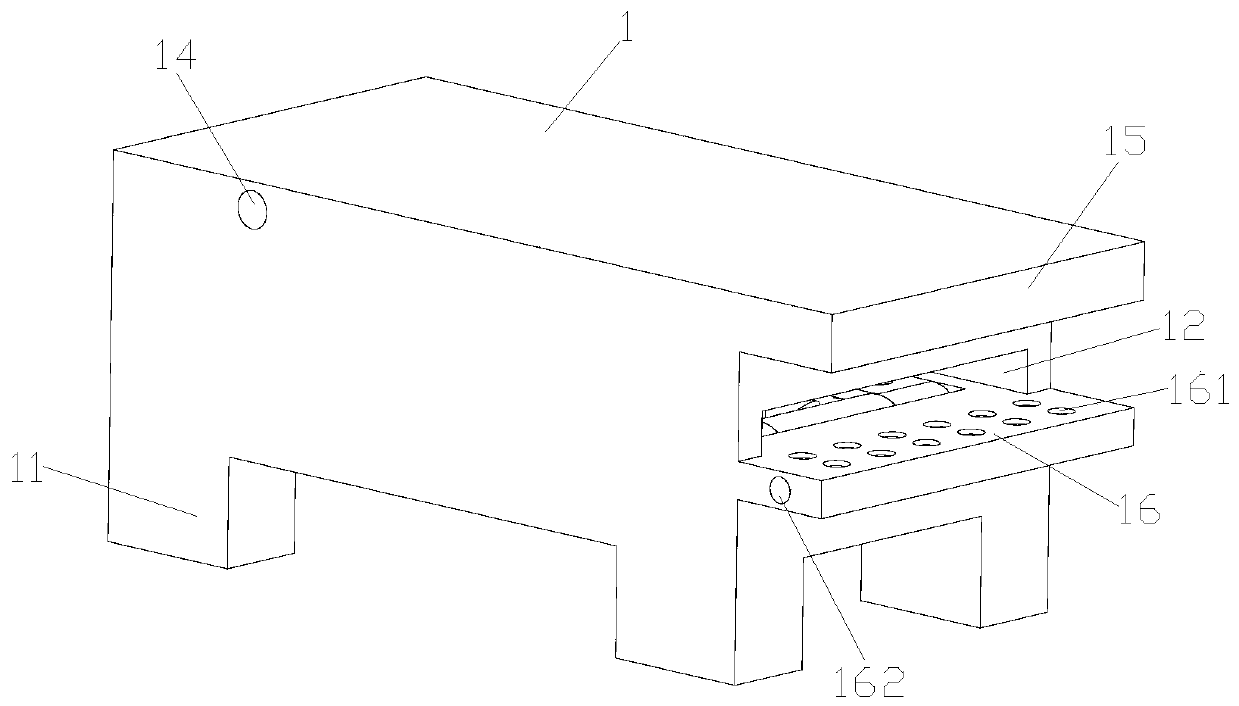

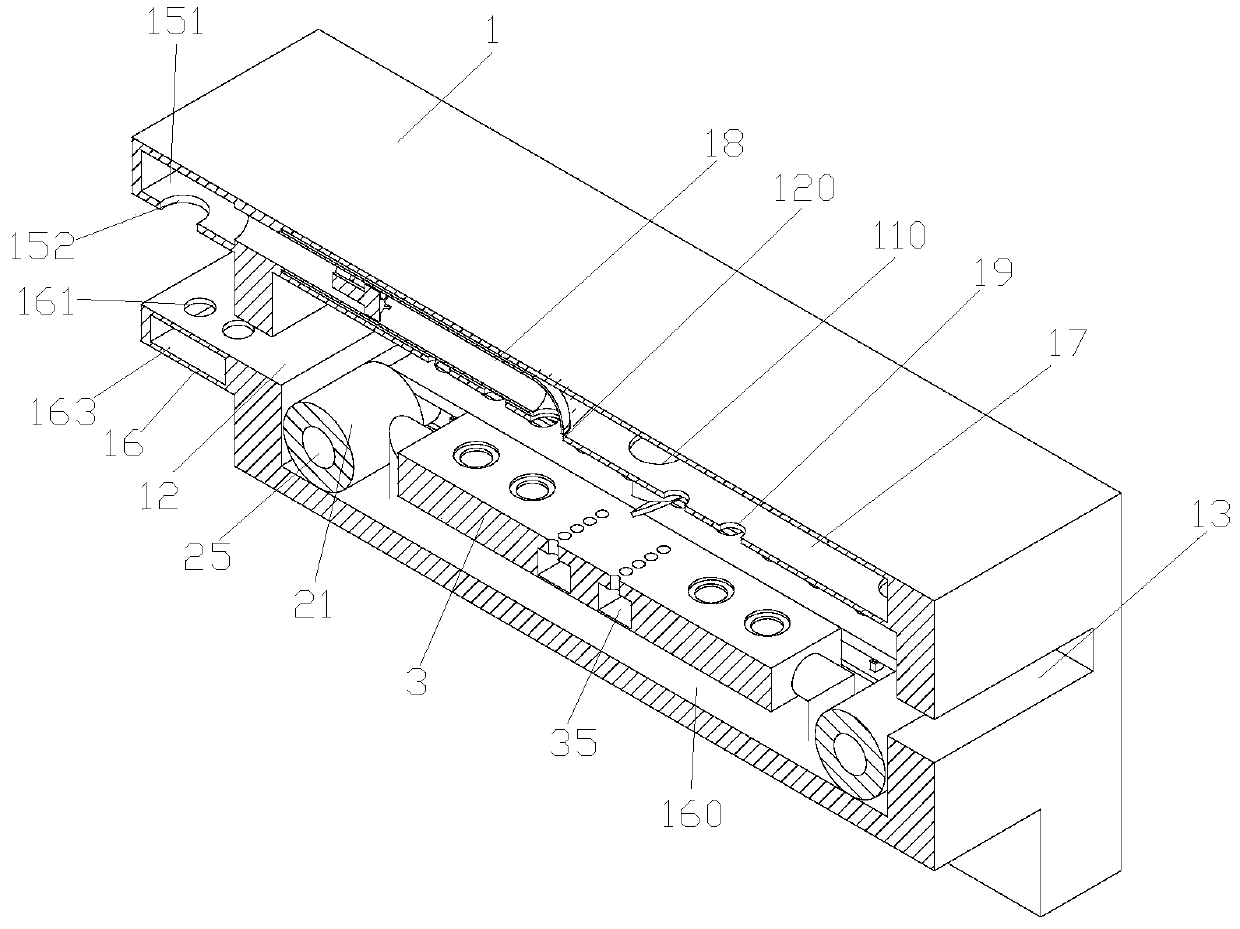

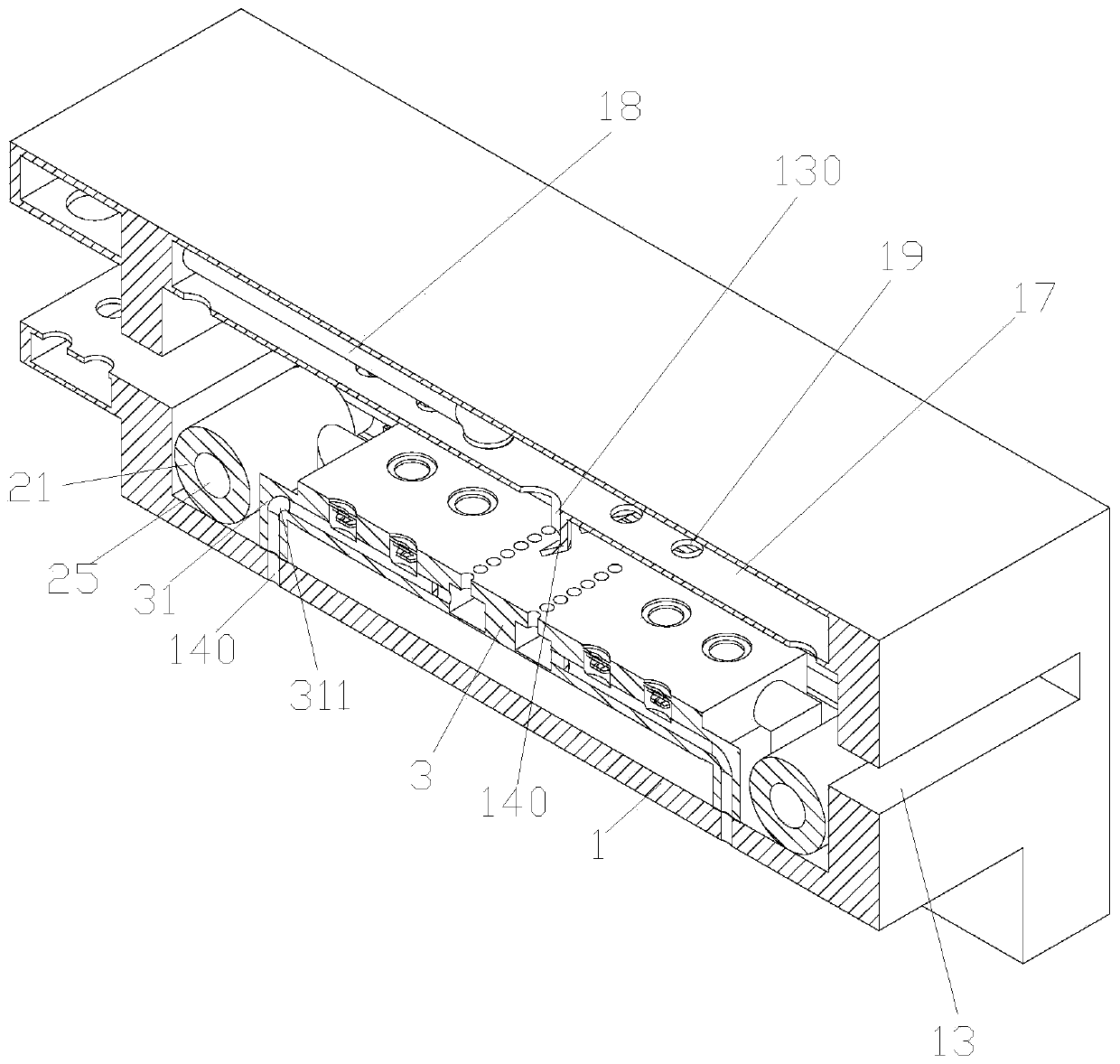

[0026] Such as Figure 1-13As shown, a printing dryer for improving the drying effect, including a box body 1, a support frame 11 arranged at the bottom of the box body 1, and a transmission component arranged in the box body 1, and the support is erected on the box body The four ends at the bottom provide support for the dryer; a drying chamber is provided in the box body 1, and an installation chamber 160 is provided at the bottom of the drying chamber, and the transmission component is arranged in the installation chamber 160, so The side wall of the box body 1 is provided with a material inlet 12, and the other side of the box body 1 is provided with a material outlet 13. , the sleeve 21 arranged on the roller 2 and the conveyor belt 22 arranged on the roller 2, the conveyor belt is made of polyurethane material to avoid damage to the fabric; there are two groups of rollers, respectively located in the installation cavity The two ends are used to fix the conveyor belt; un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com