Screen stretching method for platemaking

A technology of stretching and stretching machine, applied in the direction of printing plate preparation, printing, etc., can solve the problems of scrapping, scratching of steel mesh, high requirements for workers' professional skills and work experience, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0028] A stretching method for plate making, comprising the following steps:

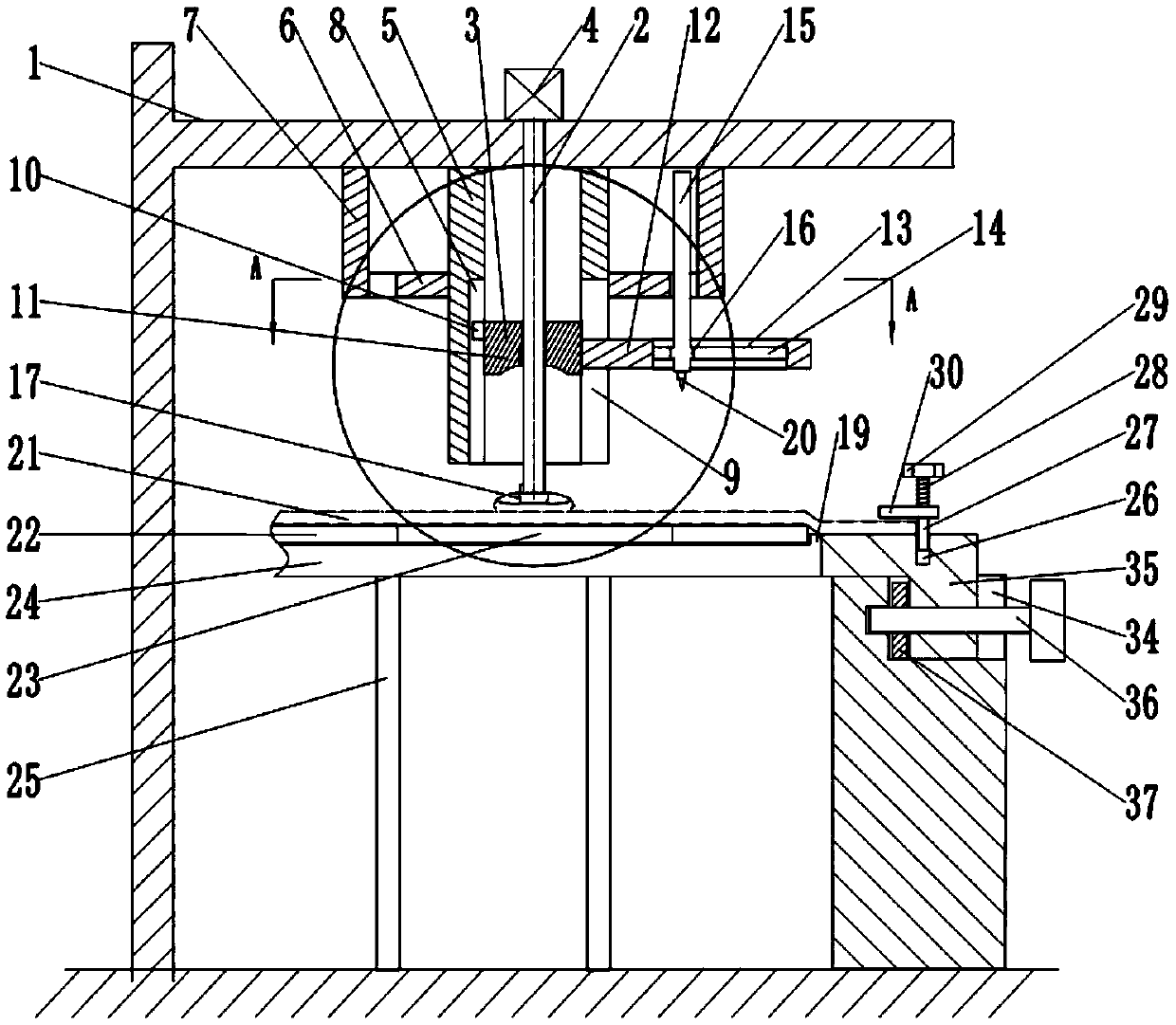

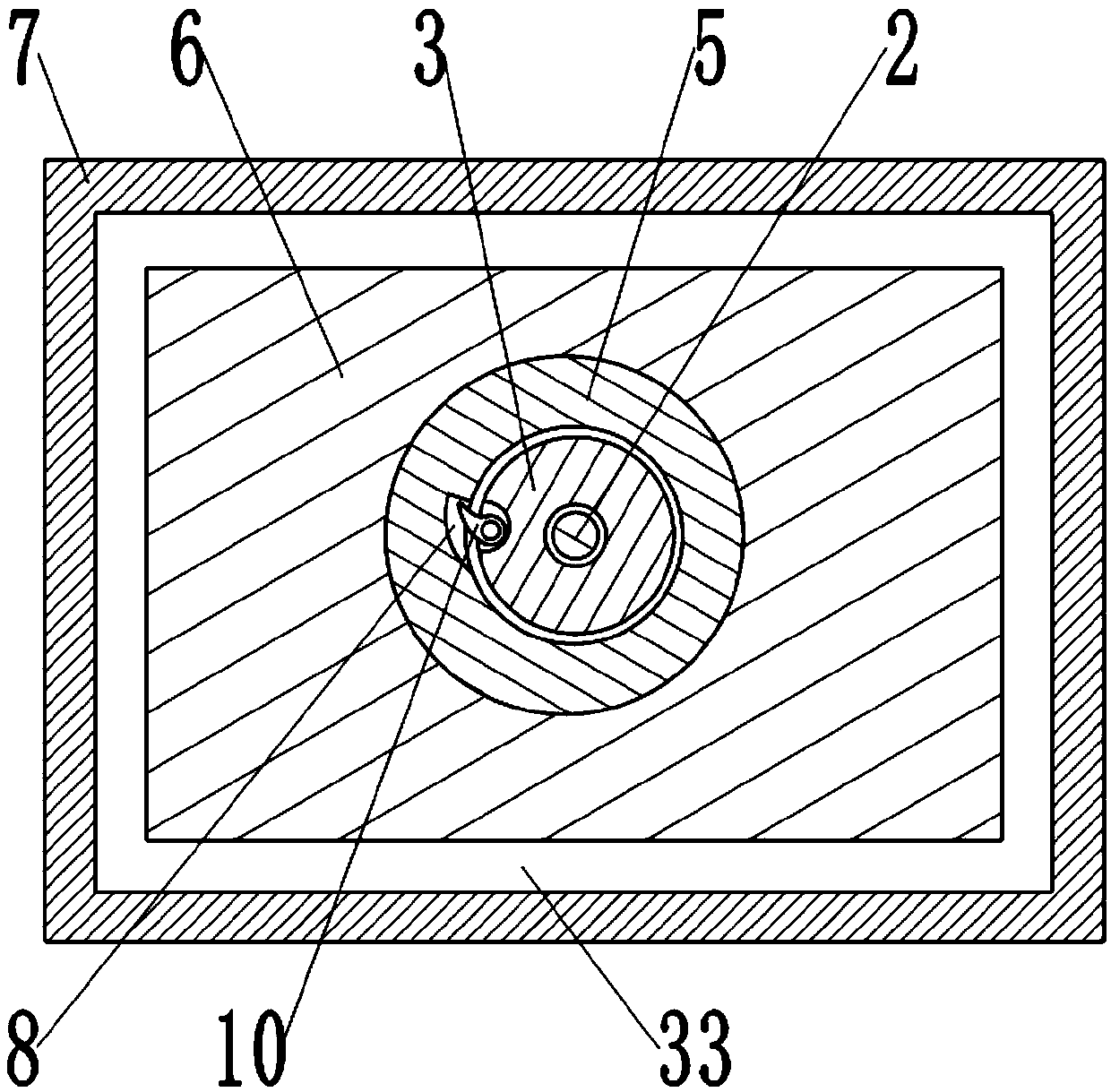

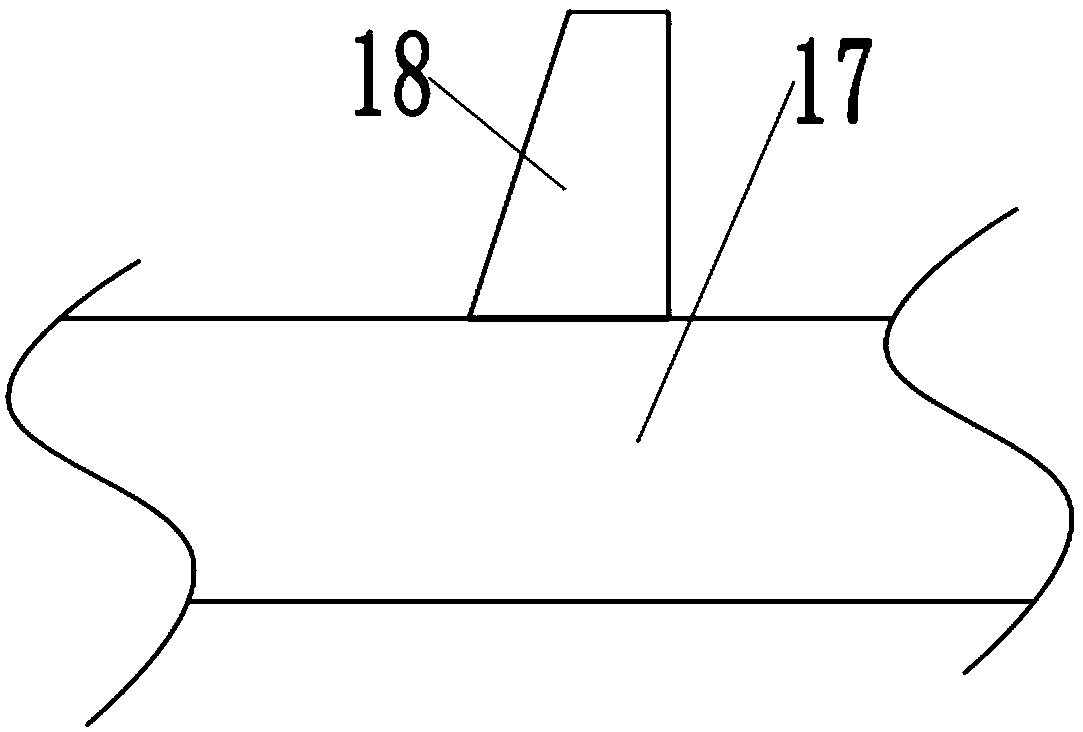

[0029] Step 1, prepare a stretching machine: such as figure 1 As shown, the stretching machine includes a frame 1, a stretching mechanism and a cutting mechanism. The stretching mechanism is slidably connected to the frame 1. The stretching mechanism is used to fix the periphery of the wire mesh 21 and make the wire mesh 21 in a tight state. The stretching mechanism includes a wire mesh chuck for clamping the edge of the wire mesh 21, and the wire mesh chuck includes a locking screw 27 and a "U" shaped clip, such as Figure 4 As shown, the clip includes a clip substrate 31 and clip legs 30 fixedly connected to both sides of the clip substrate 31 . The center of the clip substrate 31 has a locking through hole 32 for matching with the locking screw 27 . Such as figure 1 As shown, a return spring 28 is provided between the locking screw 27 and the locking through hole 32, the specific settings are a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com