Sweet potato cleaning device

A cleaning device and technology for sweet potatoes, which are applied in the fields of filtration and separation, climate change adaptation, food processing, etc., can solve the problems of insufficient attention to water resource conservation and recycling, insufficient cleaning of sweet potatoes, damage to the skin of sweet potatoes, etc., so as to facilitate cleaning of sweet potatoes. Improve the use and cleaning equipment and promote the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

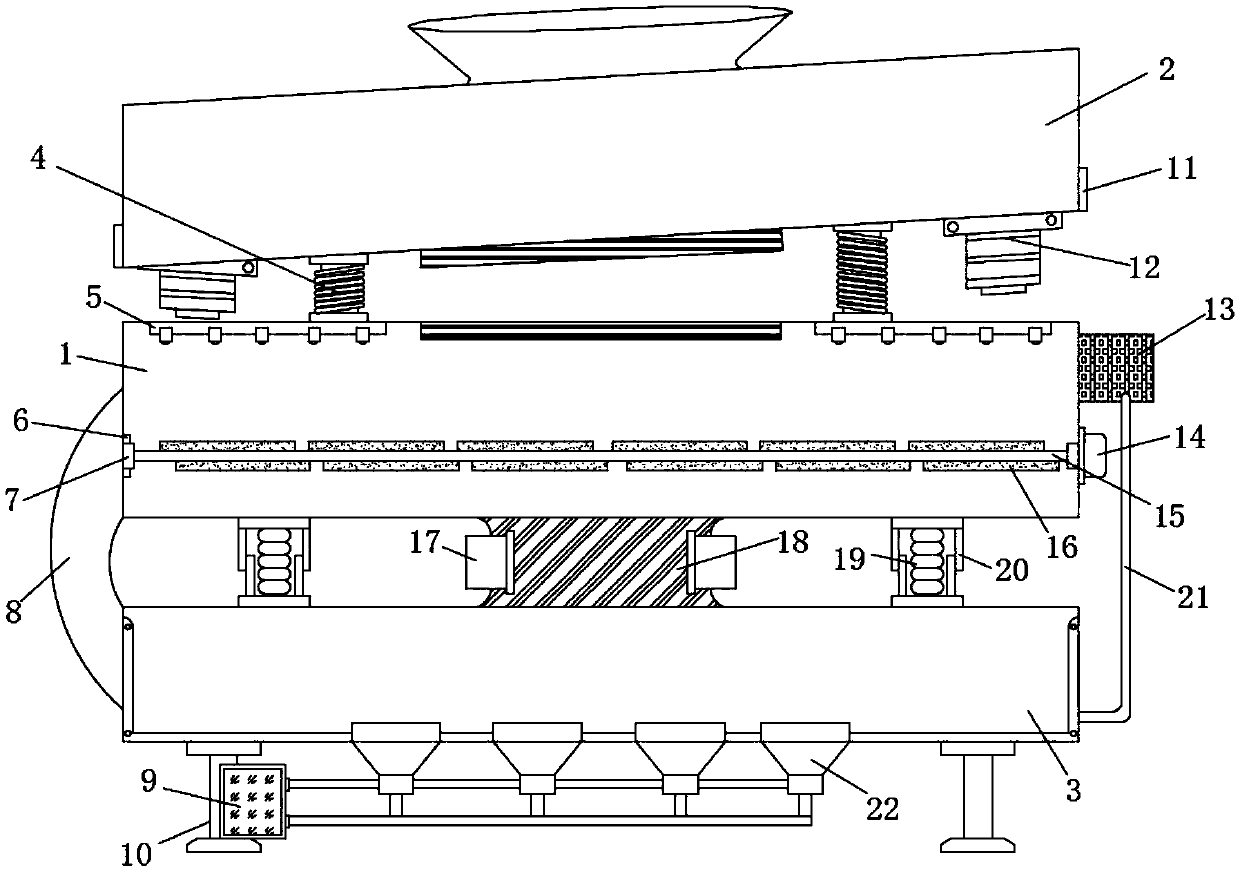

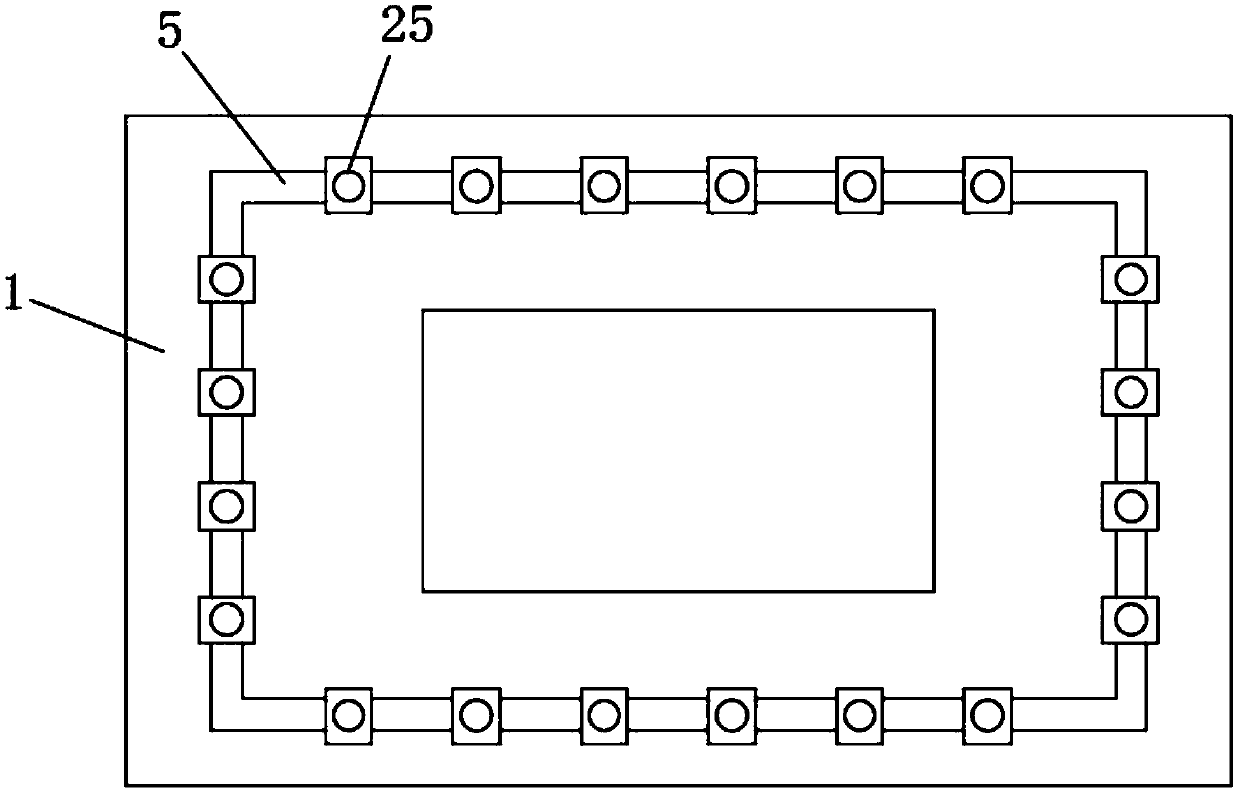

[0025] Such as figure 1 Shown, a kind of sweet potato cleaning device comprises cleaning box 1, and vibrating spring 4 is all installed on cleaning box 1 top two ends, and vibrating spring 4 top is welded with vibrating box body 2, and vibrating box body 2 is connected with cleaning box 1 by vibrating spring 4. Connection, vibrating motors 12 are installed at both ends of the bottom of the vibrating box 2, particle through holes 11 are inlaid on both sides of the vibrating box 2, water pipes 5 are inlaid on the top of the cleaning box 1, and the external side of the cleaning box 1 is provided with The high-pressure water sprayer 13 communicates with the water conduit 5.

[0026] In the present embodiment, under the combined action of the vibrating motor 12 and the vibrating spring 4, the soil particles on the surface of the sweet potato are effectively dropped due to the vibration force of the vibrating box 2, and the large pieces of soil dust on the surface of the sweet potat...

Embodiment 2

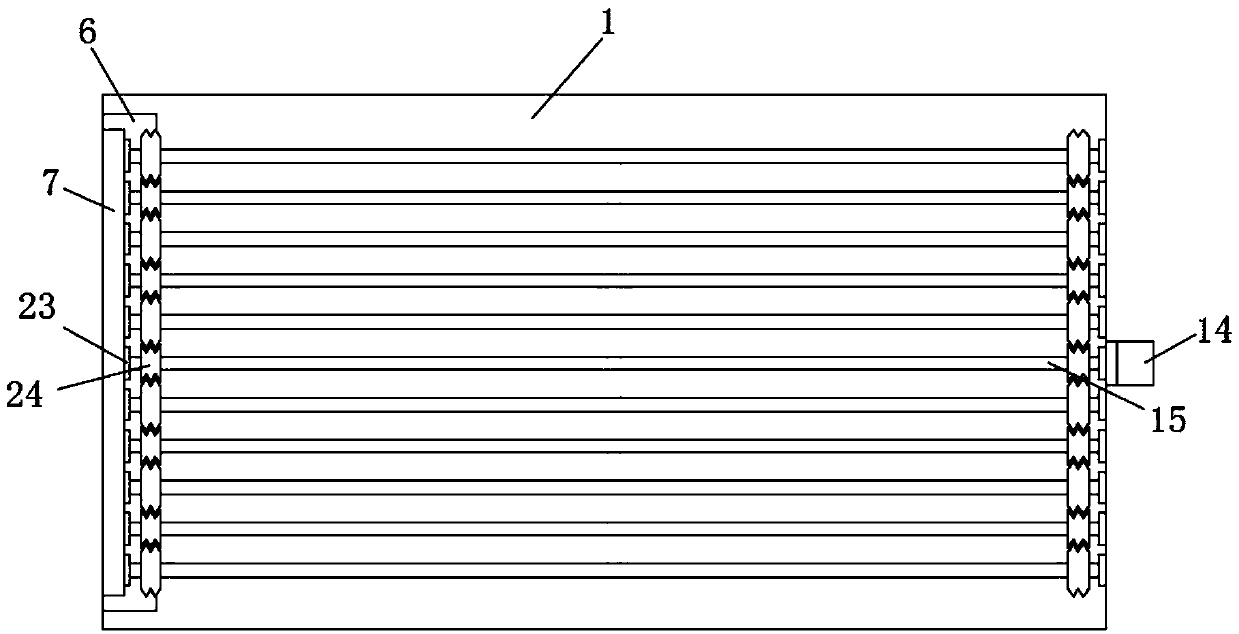

[0028] Such as Figure 1-4 As shown, both ends of the bottom of the cleaning box 1 are fixedly connected to the damping shock absorber 19, and both ends of the damping shock absorber 19 are clamped with the damping plate 20. The cleaning box 1 is connected to the cleaning tank 3 through the damping shock absorber 19, and the cleaning tank 3 An arc-shaped pipe 8 is provided on one side of the exterior, and a water pipe 21 is installed on the other side of the outside of the cleaning tank 3. The cleaning tank 3 is connected to the cleaning tank 1 through the arc-shaped pipe 8, and the cleaning tank 3 is connected to the high-pressure water jet 13 through the water pipe 21. , cleaning box 1 interior is provided with connecting rod 15, and connecting rod 15 outer rings are provided with hairbrush 16, and connecting rod 15 two ends are all equipped with bearing 23, and bearing 23 side is provided with gear 24, and connecting rod 15 passes through gear 24 and Bearing 23 is connected...

Embodiment 3

[0031] Such as figure 1 As shown, an activated carbon filter 18 is installed at the bottom of the cleaning box 1, and a cleaning tank 3 is provided at the bottom of the cleaning box 1. The cleaning box 1 is connected to the cleaning tank 3 through an activated carbon filter 18, and both sides of the external side of the activated carbon filter 18 are snapped to collect dust. Bag 17, transducer 22 is installed at the bottom of cleaning tank 3, and both ends of cleaning tank 3 bottom are provided with support frame 10, and support frame 10 is inlaid with ultrasonic frequency power supply 9, and ultrasonic frequency power supply 9 is connected with transducer 22.

[0032] In this embodiment, the activated carbon filter 18 is used to filter the sewage in the cleaning tank 1, effectively saving water resources, promoting the recycling of water resources, and cleaning again by ultrasonic waves, which can enhance the cleaning effect of sweet potatoes.

[0033] It should be noted that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com