Production process of soybean protein concentrate

A technology of concentrated soybean protein and production technology, which is applied in the field of production technology of concentrated soybean protein, can solve the problems of poor flavor and high price, and achieve the effects of improving efficiency, reducing protein denaturation, and increasing sales

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

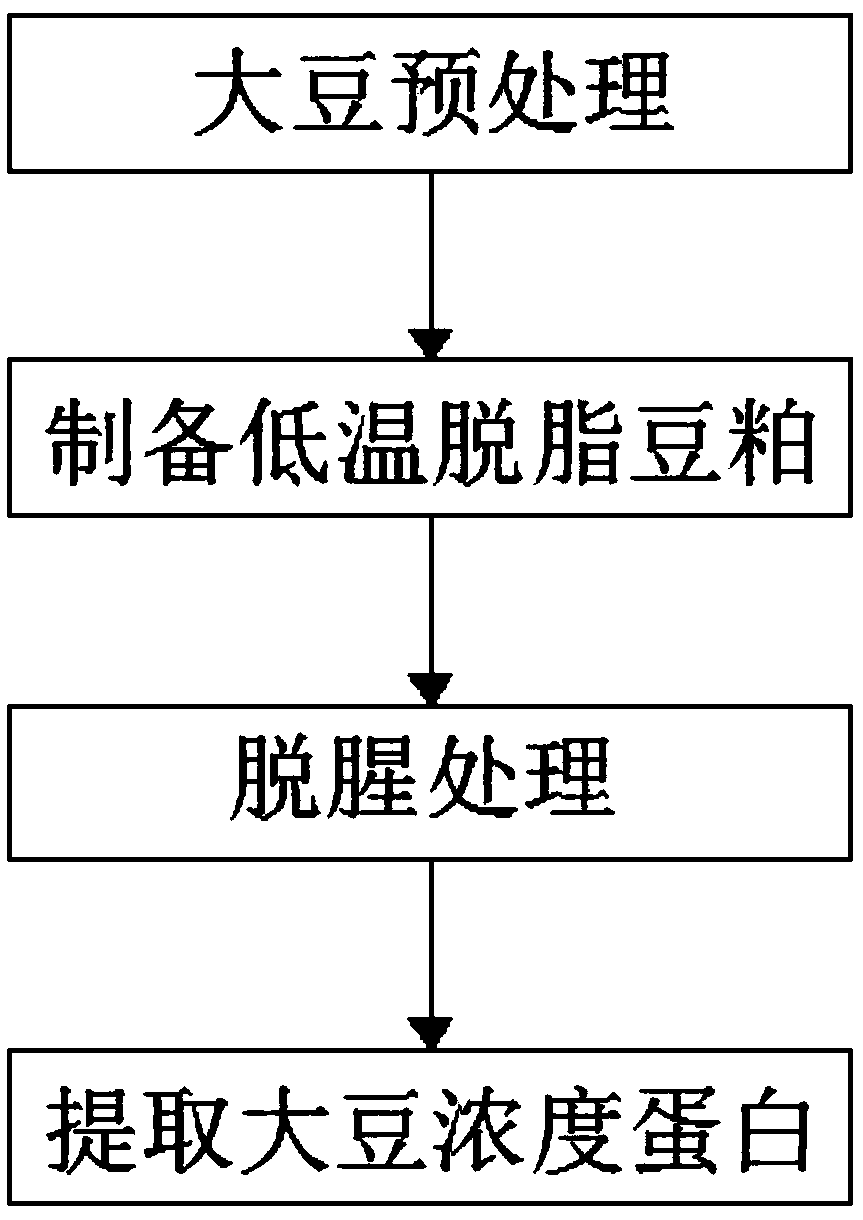

[0036] The invention discloses a production process of soybean protein concentrate. The specific steps are as follows:

[0037] (1), soybean pretreatment, adopt vegetable oil to soak soybean to reach the effect of pretreatment;

[0038] (2), prepare low-temperature defatted soybean meal, prepare low-temperature defatted soybean meal through a traditional low-temperature soybean meal production line;

[0039] (3), deodorization treatment, by preparing a flavoring agent, then adding the flavoring agent into the low-temperature defatted soybean meal, and stirring evenly;

[0040] (4) extract concentrated soybean protein, and prepare concentrated soybean protein through the preparation process of concentrated soybean protein.

[0041] Soybean pretreatment steps are:

[0042] (1), soak the soybean after cleaning with cold water for 12 hours;

[0043] (2), pull out the soaked soybeans, and dry them, and then soak them in vegetable oil for 6 hours;

[0044] (3) After the soybeans...

Embodiment 2

[0059] The invention discloses a production process of soybean protein concentrate. The specific steps are as follows:

[0060] (1), soybean pretreatment, adopt vegetable oil to soak soybean to reach the effect of pretreatment;

[0061] (2), prepare low-temperature defatted soybean meal, prepare low-temperature defatted soybean meal through a traditional low-temperature soybean meal production line;

[0062] (3), deodorization treatment, by preparing a flavoring agent, then adding the flavoring agent into the low-temperature defatted soybean meal, and stirring evenly;

[0063] (4) extract concentrated soybean protein, and prepare concentrated soybean protein through the preparation process of concentrated soybean protein.

[0064] Soybean pretreatment steps are:

[0065] (1), soak the soybean after cleaning with cold water for 12 hours;

[0066] (2), the soaked soybeans are pulled out, and dried, and then soaked in vegetable oil for 7 hours;

[0067] (3) After the soybeans...

Embodiment 3

[0082] The invention discloses a production process of soybean protein concentrate. The specific steps are as follows:

[0083] (1), soybean pretreatment, adopt vegetable oil to soak soybean to reach the effect of pretreatment;

[0084] (2), prepare low-temperature defatted soybean meal, prepare low-temperature defatted soybean meal through a traditional low-temperature soybean meal production line;

[0085] (3), deodorization treatment, by preparing a flavoring agent, then adding the flavoring agent into the low-temperature defatted soybean meal, and stirring evenly;

[0086] (4) extract concentrated soybean protein, and prepare concentrated soybean protein through the preparation process of concentrated soybean protein.

[0087] Soybean pretreatment steps are:

[0088] (1), soak the soybean after cleaning with cold water for 12 hours;

[0089] (2), pull out the soaked soybeans, and dry them, and then soak them in vegetable oil for 8 hours;

[0090] (3) After the soybeans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com