Sensing unit based on ceramic co-firing process, electrochemical gas sensor comprising sensing unit and manufacturing method of sensing unit

A technology for sensing units and manufacturing methods, applied in the direction of material electrochemical variables, etc., can solve problems such as difficult methods, complex structures, and large volumes of electrochemical gas sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0034] Specific implementation mode one: refer to figure 1 This embodiment is described in detail. The sensor unit based on the ceramic co-firing process described in this embodiment includes: a working electrode layer 1, an electrolytic cell layer 2, an auxiliary electrode layer 3 and an extraction layer 4,

[0035] The ceramic substrate of the working electrode layer 1 has a first through hole 1-3, a first electrolytic cell through hole 1-4, a second through hole 1-5 and a first through hole 1-6, and the first electrolytic cell through hole The upper opening of 1-4 is closed and covered with a catalytic electrode 1-2, and the upper surface of the catalytic electrode 1-2 is covered with a gas-permeable membrane 1-1 in a closed manner, and the material of the catalytic electrode 1-2 is noble metal, metal oxide or metal complexes;

[0036] The ceramic substrate of the electrolytic cell layer 2 is provided with a second electrolytic cell through hole 2-1, a third through hole 2...

specific Embodiment approach 2

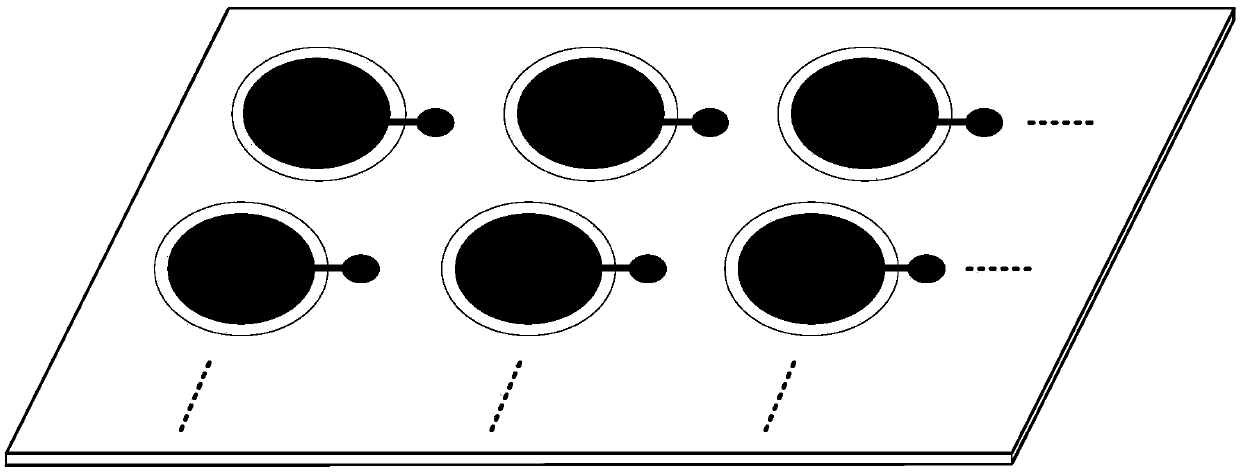

[0046] Specific implementation mode two: refer to figure 2 Specifically explaining this embodiment, the electrochemical gas sensor including the sensing unit described in Embodiment 1 in this embodiment includes a plurality of sensing units based on a ceramic co-firing process arranged in a rectangular array.

[0047] In this embodiment, each sensing unit realizes the preparation of various gas sensors by immobilizing different types of electrolytes and printing catalytic electrodes of different types of catalytic electrode materials.

specific Embodiment approach 3

[0048] Embodiment 3: This embodiment is a method for manufacturing the sensing unit described in Embodiment 1, which includes the following steps:

[0049] Step 1: Prepare the first through hole 1-3, the first electrolytic cell through hole 1-4, the second through hole 1-5 and the first through hole 1- 6. Prepare the second electrolytic cell through hole 2-1, the third through hole 2-2, the fourth through hole 2-3 and the second through hole 2-4 on the ceramic substrate of the electrolytic cell layer 2, and the auxiliary electrode layer 3 preparing a third via hole 3-2, a fourth via hole 3-3 and a fifth via hole 3-5 on the ceramic substrate;

[0050] Use the screen printing method to print conductive wires in the first via hole 1-6, the second via hole 2-4, the third via hole 3-2, the fourth via hole 3-3 and the fifth via hole 3-5. Metal;

[0051] Utilize screen printing to print lead wires on the ceramic substrate upper surface of the working electrode layer 1 respectively,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com