Sample injector for measuring properties of wax oil with high solidifying point

A technology of sample injectors and properties, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of high cost of personnel and equipment and instruments, many toxic and harmful chemical reagents, and great harm to human health, and achieve the cost of personnel and Low cost of equipment and instruments, less toxic and harmful chemical reagents, and less chemical reagents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Measurement of Colloidal Properties of Kazakhstan Train Wax Oil

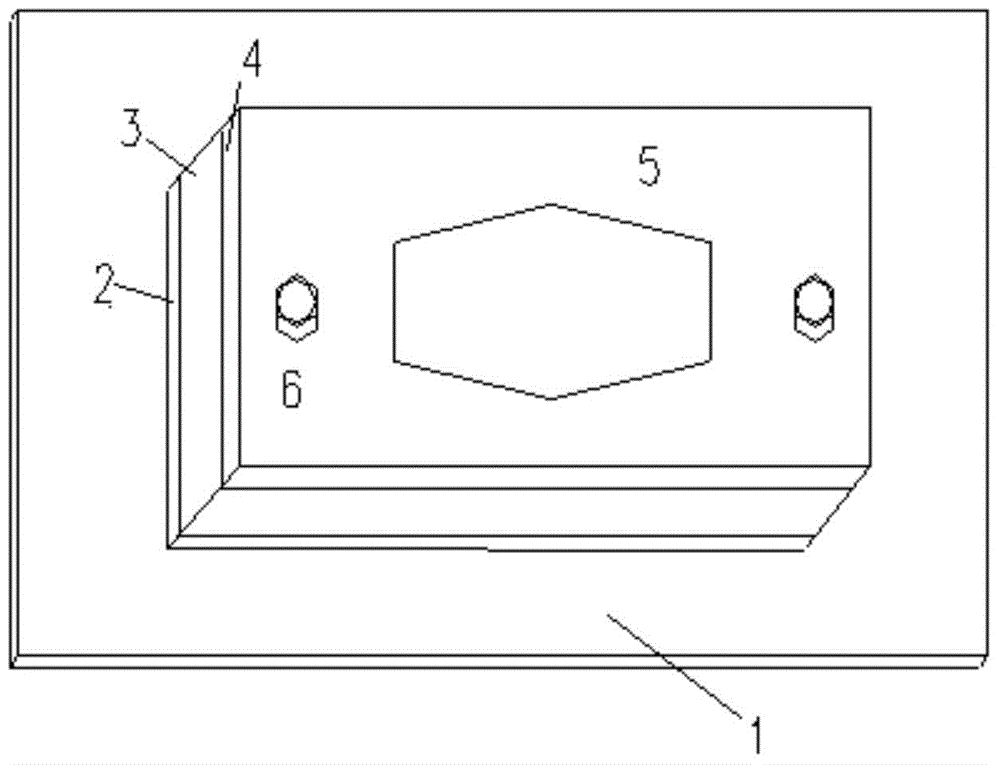

[0031] Using a special sampler for measuring high freezing point wax oil with a near-infrared instrument, first install an oil-resistant rubber gasket on the surface of the sample cell clamp of the near-infrared instrument. Fluoroethylene sealing gasket, and then use the positioning bolts to connect and fix the sample cell clip of the external instrument, oil-resistant rubber sealing gasket, quartz wound piece, and PTFE sealing gasket. A sample pool is formed in the enclosed space.

[0032] Heat the Kazakhstan train wax oil that cannot be sampled at room temperature to 80°C to soften or liquefy and inject it into the sample cell of the special sample injector. When the sample is softened or liquefied, scrape the sample cell with a glass scraper. After cooling to 30°C for solidification and molding, a sample area is formed in the space surrounded by the quartz wound piece, the PTFE gasket, and the positio...

Embodiment 2

[0036] Measurement of asphaltene properties of mixed wax oil in northern Karamay

[0037] Use a special sample injector to first install an oil-resistant rubber gasket on the surface of the near-infrared instrument sample cell clamp, install a quartz wound piece on the oil rubber gasket, install a polytetrafluoroethylene gasket on the quartz wound piece, and then use the positioning bolt to install the outer The instrument sample cell clamp, oil-resistant rubber gasket, quartz wound piece, and polytetrafluoroethylene gasket are connected and fixed, and a sample pool is formed in the space surrounded by the quartz wound piece, polytetrafluoroethylene gasket, and positioning bolts.

[0038] The Karamay northern Xinjiang mixed wax oil that cannot be sampled at room temperature is heated to 70°C to soften or liquefy, and then injected into the sample pool of the special sample injector. After the sample is cooled to 40°C to solidify and form, a sample area is formed in the space s...

Embodiment 3

[0042] Measurement of Aromatics Properties of Huoshaoshan Wax Oil in Dongjiang Oilfield

[0043] Using a special sampler for measuring high freezing point wax oil with a near-infrared instrument, first install an oil-resistant rubber gasket on the surface of the sample cell clamp of the near-infrared instrument. Fluoroethylene sealing gasket, and then use the positioning bolts to connect and fix the sample cell clip of the external instrument, oil-resistant rubber sealing gasket, quartz wound piece, and PTFE sealing gasket. A sample pool is formed in the enclosed space.

[0044] Heat the Huoshaoshan wax oil from Dongjiang Oilfield, which cannot be sampled at normal temperature, to 90°C to soften or liquefy and inject it into the sample pool of the special sample injector. When the sample is softened or liquefied, scrape the sample pool with a glass scraper. After the sample is cooled to 45°C and solidified and formed, the sample area is formed in the space surrounded by the q...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com