Desulfurization wastewater droplet evaporation test device and method

A technology for desulfurization wastewater and droplet evaporation, which is used in measuring devices, material excitation analysis, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

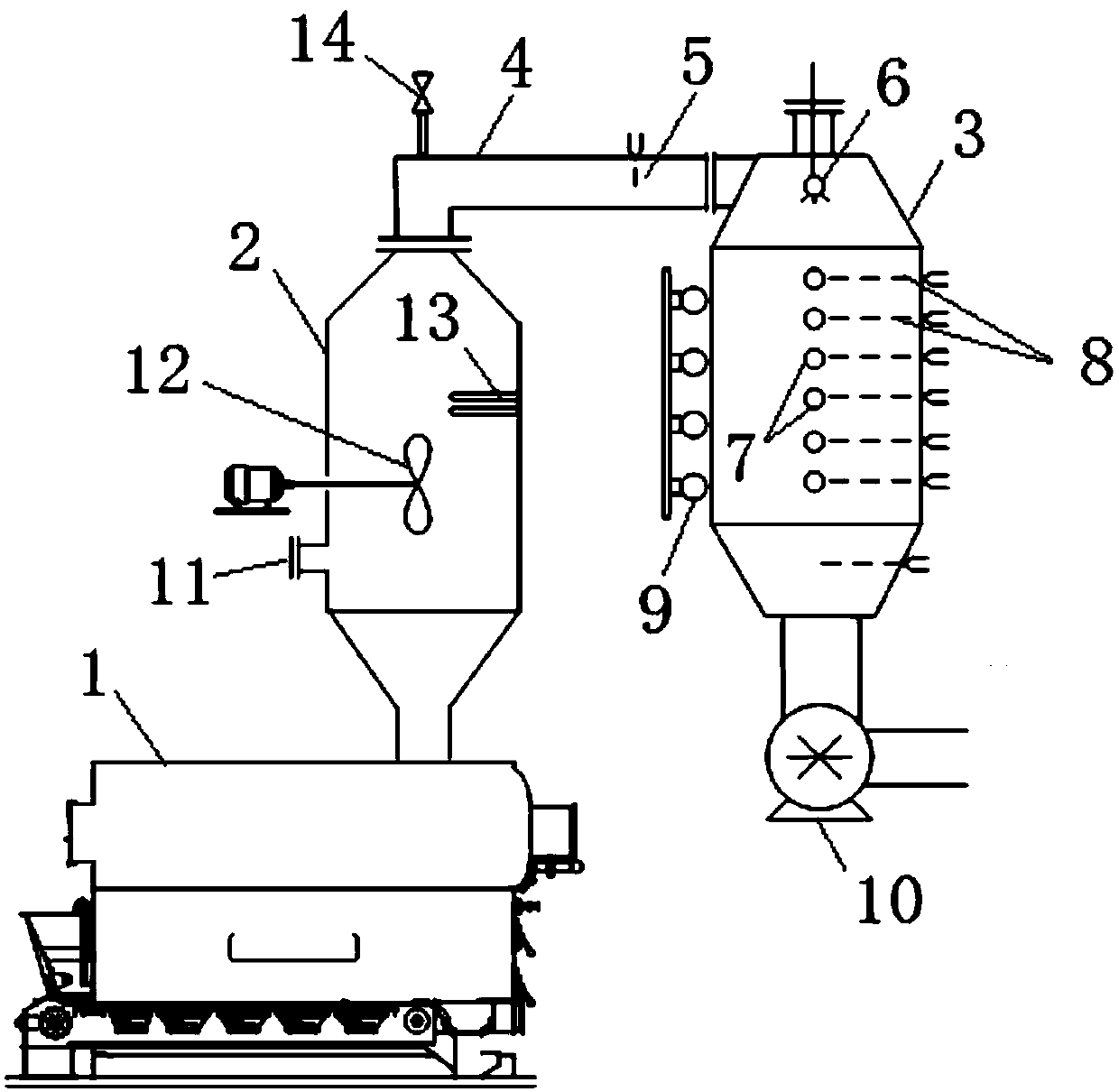

[0032] The present invention will be further described below in conjunction with accompanying drawing.

[0033] Such as figure 1 As shown, a desulfurization wastewater droplet evaporation test device includes a coal-fired boiler 1 and a buffer tank 2 and an evaporation chamber 3 arranged side by side above the coal-fired boiler 1, the flue gas outlet end of the coal-fired boiler 1 and the buffer tank 2 The lower inlet end is connected. In order to simulate different flue gas environments according to the needs, the buffer tank 2 is provided with a vent 11 near the lower inlet end; the upper outlet end of the buffer tank 2 communicates with the upper inlet end of the evaporation chamber 3 through the pipeline 4 ; The pipeline 4 is provided with a temperature and humidity sensor-5;

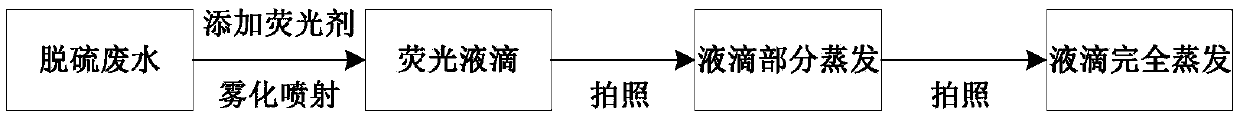

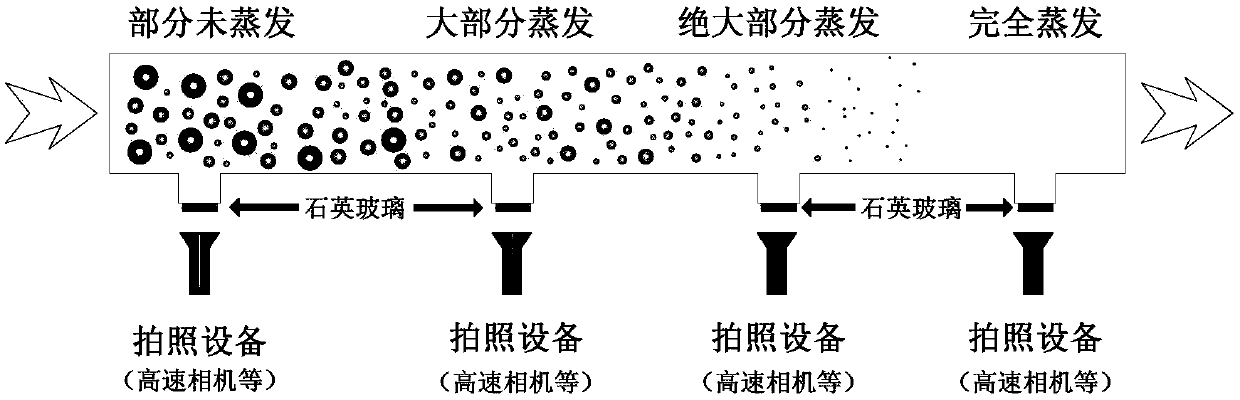

[0034] A nozzle 6 is arranged above the interior of the evaporation chamber 3, and the nozzle 6 communicates with the desulfurization wastewater added with a fluorescent agent through a liquid supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com