Method for determining reasonable design area of roots pump rotor molding line and application of method

A technology of rotor profile and rational design, applied to pumps, pump components, mechanical equipment, etc., can solve problems such as improper selection of design parameters, and achieve the effect of improving design efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

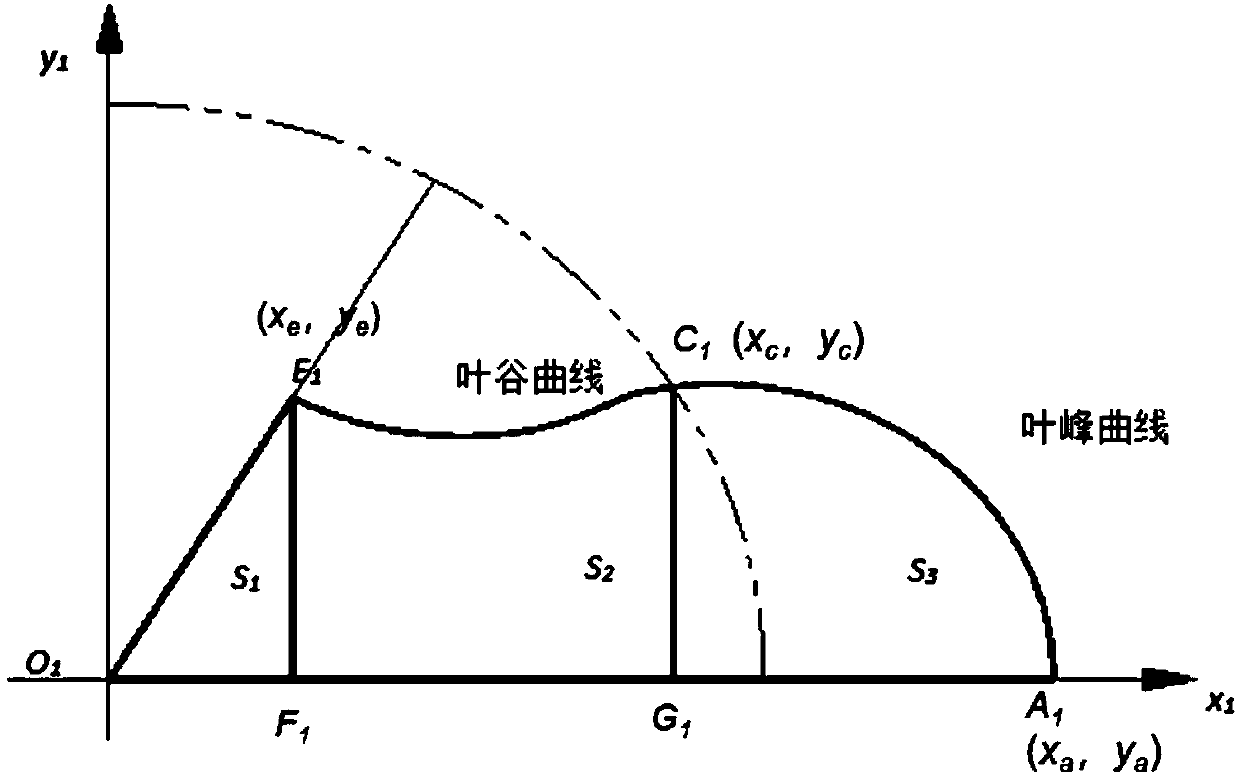

[0065] This embodiment provides a method for determining the reasonable design area of the Roots pump rotor profile, see figure 1 , the method includes:

[0066] Step 1: Establish the relationship between the rotor profile and performance parameters of the Roots pump; use the pumping rate of the Roots pump as an index to measure the performance of the Roots pump. The Roots pump has two rotors, and each rotor has Z teeth, where Z is an integer greater than or equal to 2. The embodiment of the present invention is described by taking Z=3 as an example.

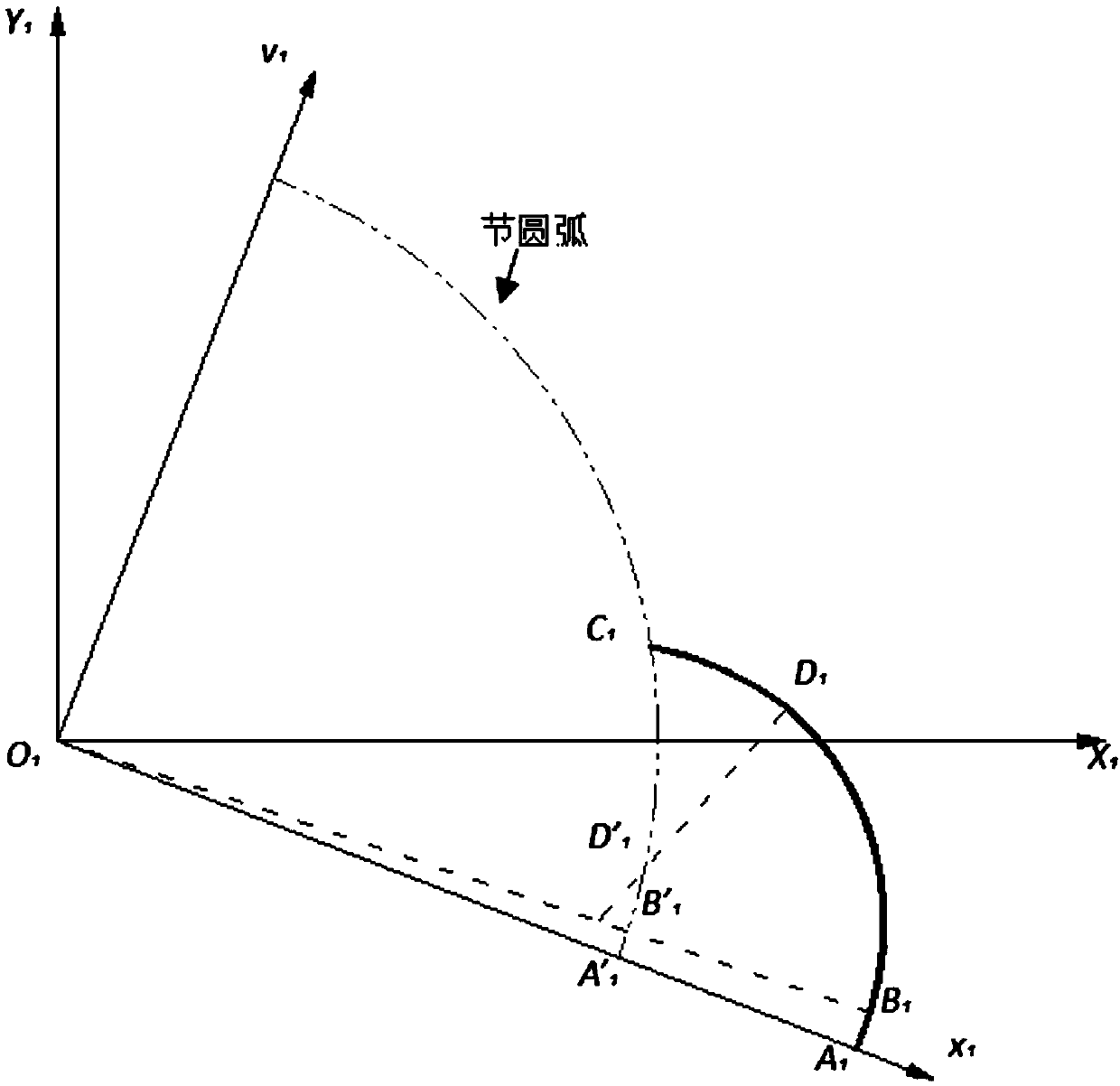

[0067] Such as figure 1 As shown in (a), the shape of the two rotors of the Roots pump is the same. Further, the tooth profile on each tooth of the rotor is the same, and the tooth profile on each tooth is axisymmetric. Such as figure 1 As shown in (b), the tooth profile on half a tooth is composed of a blade peak curve and a blade valley curve, bounded by the pitch circle, the part outside the pitch circle is called the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com