Hydroxyl oxidize iron nano array, and preparation method and application thereof

A technology of iron oxyhydroxide and nano-array, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of anti-oxidation, poor corrosion resistance, high cost of carbon paper and carbon cloth, complicated processing process, etc., and achieve low cost , Excellent electrochemical catalytic performance and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

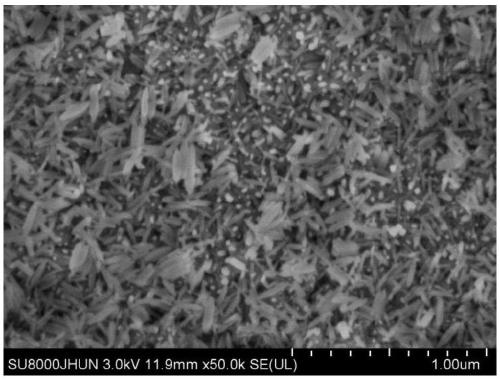

[0041] Weigh 9mmol ferric chloride (concentration: 0.3mol / L) and 6mmol sodium nitrate and dissolve them in 60mL deionized water. After the dissolution is complete, a yellow solution is obtained. Ultrasonic cleaning with L hydrochloric acid and deionized water, then pour the mixed solution of ferric chloride and sodium nitrate into a 100mL hydrothermal reaction kettle, and immerse the cleaned stainless steel mesh in the solution, and then put the reaction kettle into a blast oven Inside, heat at 160° C. for 1 hour, take out the stainless steel mesh and dry it at low temperature to obtain the iron oxyhydroxide nano-array supported by the stainless steel mesh. figure 1 It is the SEM image of the iron oxyhydroxide nanoparticles loaded on the stainless steel mesh prepared in Example 1.

Embodiment 2

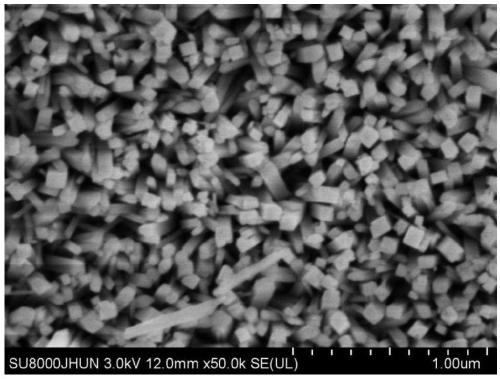

[0043] Weigh 9mmol ferric chloride (concentration: 0.1mol / L) and 6mmol sodium nitrate and dissolve them in 60mL deionized water. After the dissolution is complete, a yellow solution is obtained. Ultrasonic cleaning with L hydrochloric acid and deionized water, then pour the mixed solution of ferric chloride and sodium nitrate into a 100mL hydrothermal reaction kettle, and immerse the cleaned stainless steel mesh in the solution, and then put the reaction kettle into a blast oven Inside, heat at 40° C. for 24 hours, take out the stainless steel mesh and dry it at low temperature to obtain the stainless steel mesh-supported iron oxyhydroxide nano-array.

Embodiment 3

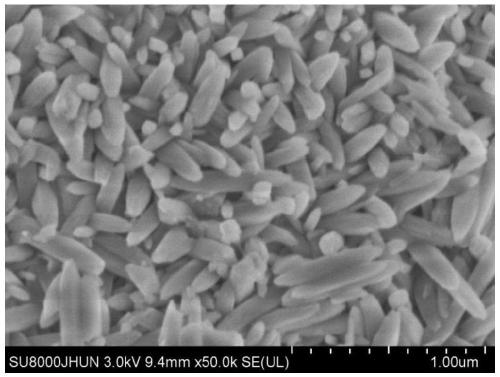

[0045] Weigh 9mmol (concentration: 0.05mol / L) ferric chloride and 6mmol sodium nitrate and dissolve them in 60mL deionized water. After the dissolution is complete, a yellow solution is obtained. Ultrasonic cleaning with L hydrochloric acid and deionized water, then pour the mixed solution of ferric chloride and sodium nitrate into a 100mL hydrothermal reaction kettle, and immerse the cleaned stainless steel mesh in the solution, and then put the reaction kettle into a blast oven Inside, heat at 80° C. for 12 hours, take out the stainless steel mesh and dry it at low temperature to obtain the iron oxyhydroxide nano-array supported by the stainless steel mesh. figure 2 It is the SEM image of the iron oxyhydroxide nano-array loaded on the stainless steel mesh prepared in Example 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com