3D printing powder and preparation method thereof

A 3D printing and powder technology, applied in the field of 3D printing materials, can solve the problems of high cost and unsatisfactory performance, and achieve the effect of low cost, good toughness and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

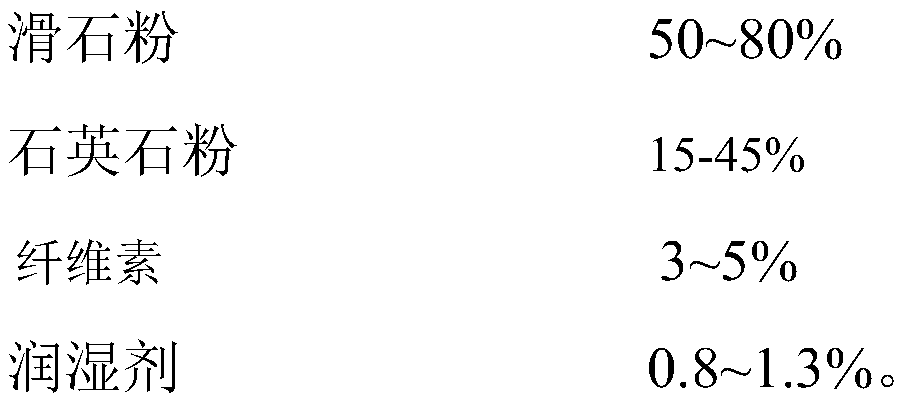

[0022] A kind of 3D printing powder, its raw material comprises by mass percentage:

[0023]

[0024] Further, the particle size of the talc powder is 150-800 mesh, and the particle size of the quartz stone powder is 150-800 mesh.

[0025] In the ingredients, increasing the proportion of talcum powder can improve the spreadability of the powder; increasing the proportion of quartz stone powder can improve the strength of the part (or model); as a binder, cellulose can be used to improve the part (or model) Toughness, but also improve its impact or vibration resistance; wetting agent is used to improve the wetting performance of powder and binder.

[0026] Simultaneously in the present invention, the size of raw material particle diameter has crucial effect to the production process of the printing powder of the present invention and final product, and raw material particle diameter is too small, the surface roughness of the part (or model) that is prepared into with powder ...

Embodiment 2

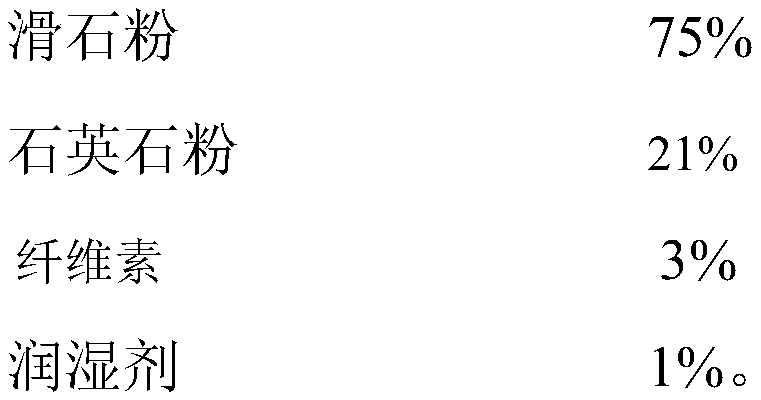

[0037] A kind of 3D printing powder, its raw material comprises by mass percentage:

[0038]

[0039] The wetting agent selected in this embodiment is ethanol.

[0040] Further, the particle size of the talc powder is 300 mesh, and the particle size of the quartz stone powder is 300 mesh.

[0041] The preparation method comprises the following steps:

[0042] (1) According to the corresponding ratio, the quartz stone powder and the particle diameter are mixed evenly with 250 mesh cellulose;

[0043] (2) Pour the wetting agent into the mixed material in step (1) and mix evenly;

[0044] (3) Pour the talcum powder into the mixed material in step (2) and mix evenly;

Embodiment 3

[0047] A kind of 3D printing powder, its raw material comprises by mass percentage:

[0048]

[0049] The wetting agent used in this example is prepared by mixing ethane and propane in a ratio of 1:1.

[0050] Further, the particle size of the talc powder is 300 mesh, and the particle size of the quartz stone powder is 300 mesh.

[0051] The preparation method comprises the following steps:

[0052] (1) According to the corresponding ratio, the quartz stone powder and the particle diameter are mixed evenly with 280 mesh cellulose;

[0053] (2) Pour the wetting agent into the mixed material in step (1) and mix evenly;

[0054] (3) Pour the talcum powder into the mixed material in step (2) and mix evenly;

[0055] (4) Seal the package to obtain the 3D printing powder of the embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com