Underwater fence board preparation and positioning installation method and underwater fence board positioning installation system

A technology for positioning installation and fence boards, which is applied in the directions of transportation, packaging, and load hanging components, etc., which can solve the problems of high cost, complicated preparation of fence boards, and increased installation and construction costs of fence boards, and achieve accurate installation, simple preparation and low cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

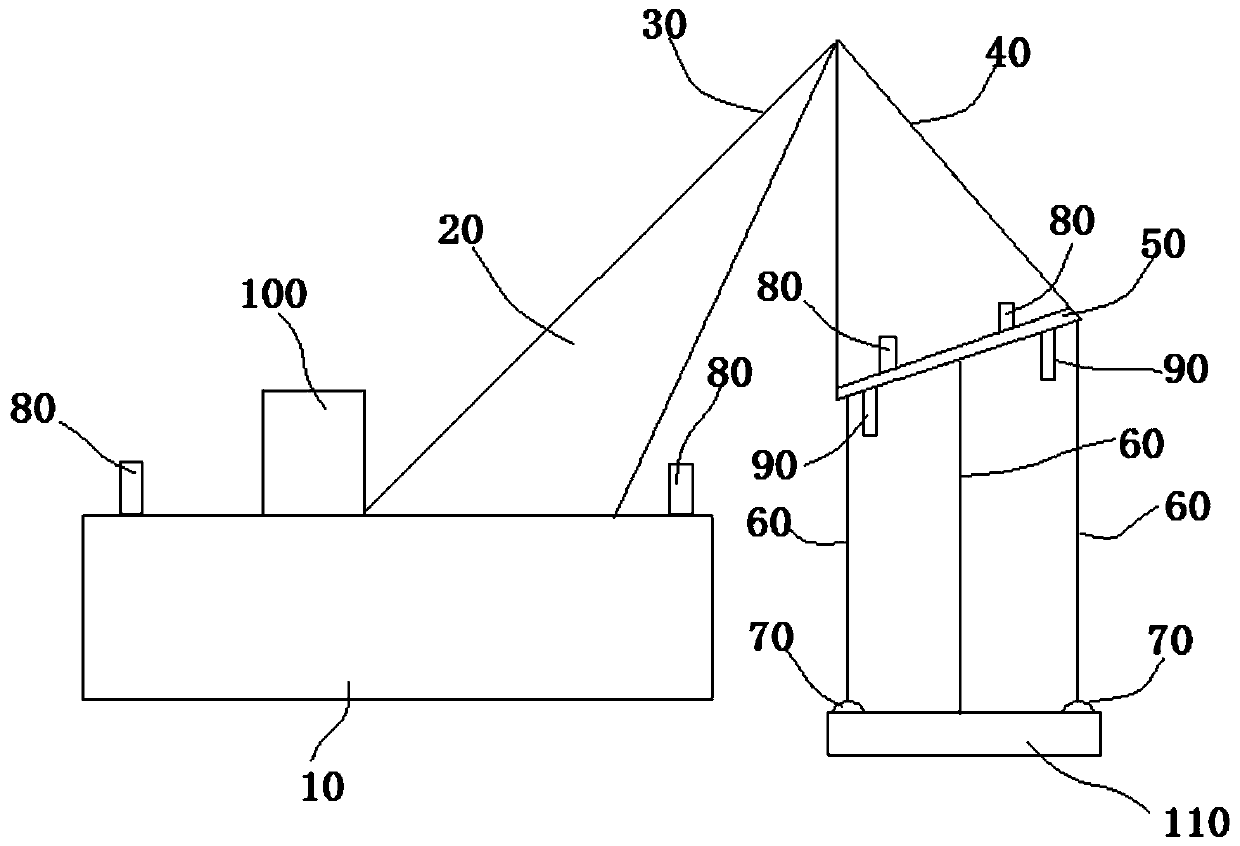

[0041] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

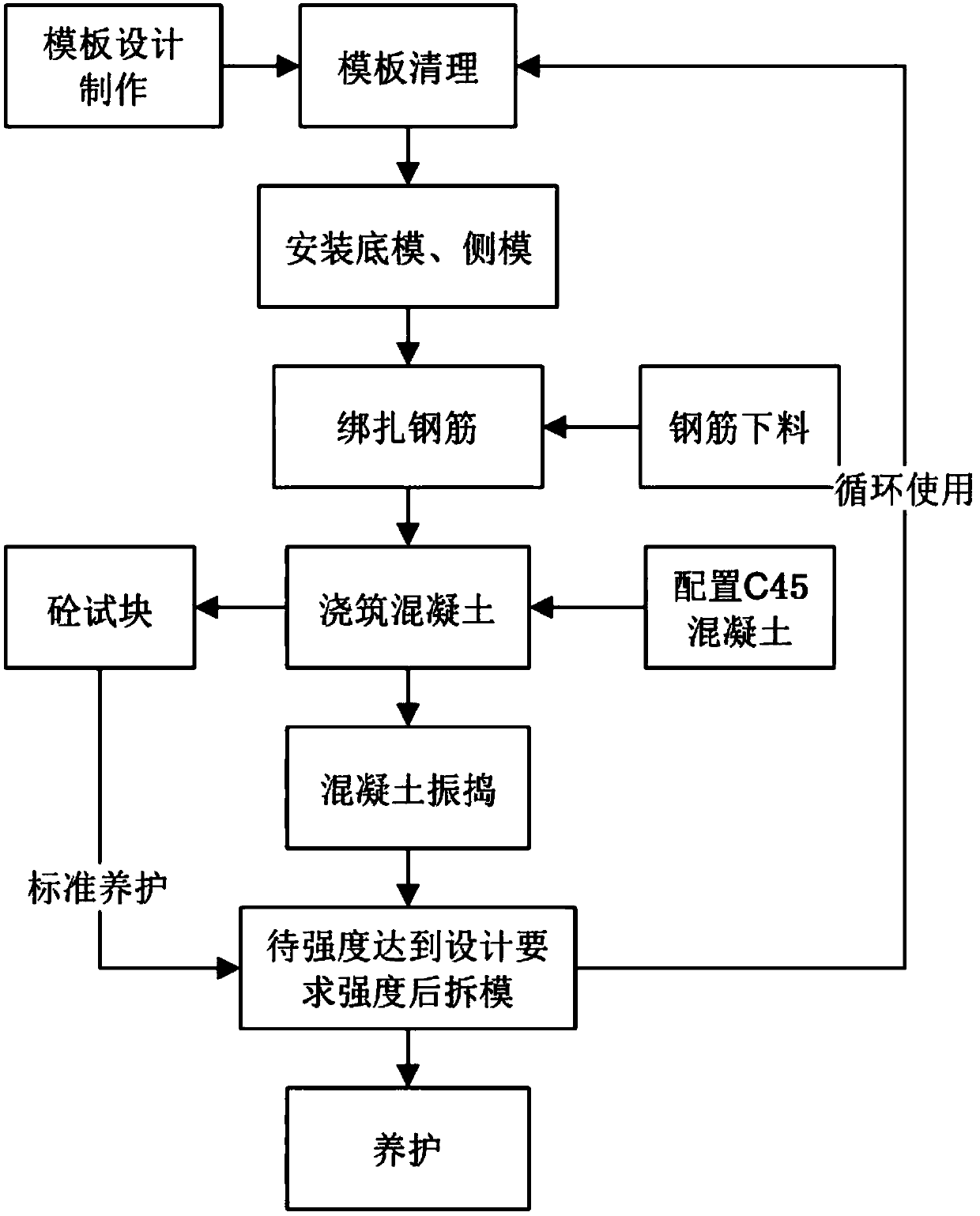

[0042] see figure 1 and figure 2 As shown, the present invention discloses an underwater fence board preparation, positioning and installation method, which is characterized in that the preparation, positioning and installation method includes the following steps:

[0043] (1), fence board preparation

[0044] (1.1) Clean up the formwork to be smooth and clean, and apply the release agent continuously and evenly; the formwork is made of steel formwork, and the thickness of the formwork is 6mm; this step can also include formwork design and manufacture, and customize the formwork that meets the fence board according to requirements;

[0045] (1.2) Install the bottom mold and side mold, and fasten them with bolts when joining the molds. There s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com