A method for preparing powder metallurgy tensile eutectic high-entropy alloys by 3D printing

A high-entropy alloy, 3D printing technology, applied in the directions of additive manufacturing, energy efficiency improvement, process efficiency improvement, etc., can solve the problems of increasing technical development difficulty, increasing technical difficulty, lack of reference blueprint, etc. Process optimization, superior performance, and the effect of increasing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1 (success)

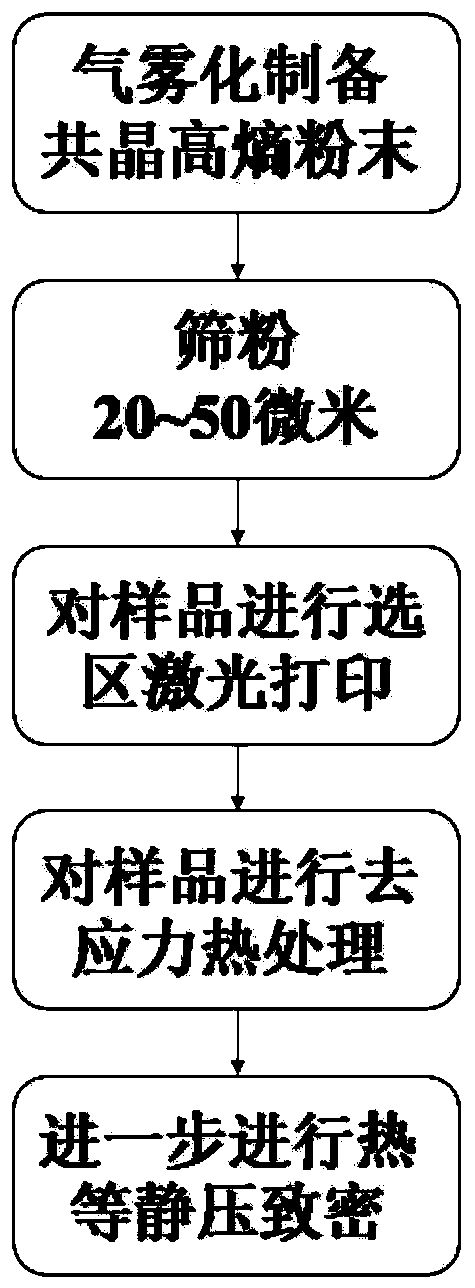

[0034] Preparation of FeCoCrNiTa Eutectic High Entropy Alloy Powder Cr by Gas Atomization 20 Fe 28 co 22 Ni 17 Ta 13 (The ratio mentioned above is the molar ratio), and then further sieved, and the powder with a particle size within 5 to 50 microns is used for selective laser cladding, and the substrate preheating temperature is 80°C. The laser power used for printing is 200W, the laser printing speed is 1000m / s, and the atmosphere is argon. Then cool down with the furnace.

[0035] The printed samples were taken out in a muffle furnace for stress relief annealing, the heating rate was 40°C / min, the holding temperature was 300°C, and the holding time was 3 hours. Then cool in the oven. In order to further increase the density of the material, the sample was subjected to hot isostatic pressing treatment. As for the pressure at 900°C, the pressure was 20MPa, and the holding time was 1 hour.

Embodiment 2

[0036] Example 2 (success)

[0037] Preparation of FeCoCrNiTa Eutectic High Entropy Alloy Powder Cr by Gas Atomization 21 Fe 27 co 23 Ni 16 Ta 13 (The ratio mentioned above is the molar ratio), and then further sieved, and the powder with a particle size within 5 to 50 microns is used for selective laser cladding, and the substrate preheating temperature is 90°C. The laser power used for printing is 300W, the laser printing speed is 1200m / s, and the atmosphere is argon. Then cool down with the furnace.

[0038]After the printed samples were taken out, they were subjected to stress relief annealing in a muffle furnace. The heating rate was 40°C / min, the holding temperature was 300°C, and the holding time was 4 hours. Then cool in the oven. In order to further improve the density of the material, the sample was subjected to hot isostatic pressing treatment. As for 1000°C, the pressure was 30 MPa, and the holding time was 2 hours.

Embodiment 3

[0039] Example 3 (success)

[0040] Preparation of FeCoCrNiTa Eutectic High Entropy Alloy Powder Cr by Gas Atomization 21 Fe 27 co 23 Ni 16 Ta 13 (The ratio mentioned above is the molar ratio), and then further sieved, and the powder with a particle size within 5 to 50 microns is used for selective laser cladding, and the substrate preheating temperature is 100°C. The laser power used for printing is 400W, the laser printing speed is 1400m / s, and the atmosphere is argon. Then cool down with the furnace.

[0041] The printed samples were taken out and placed in a muffle furnace for stress relief annealing at a heating rate of 40°C / min, a holding temperature of 400°C, and a holding time of 5 hours. Then cool in the oven. In order to further improve the density of the material, the sample was subjected to hot isostatic pressing treatment. As for the pressure at 1100°C, the pressure was 40 MPa, and the holding time was 3 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap