A hot rolling equipment for aluminum foam sandwich panel

A sandwich panel and aluminum foam technology, which is applied in metal processing equipment, workpiece surface treatment equipment, metal rolling, etc., can solve the problems of increasing equipment production costs and achieve the effect of saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

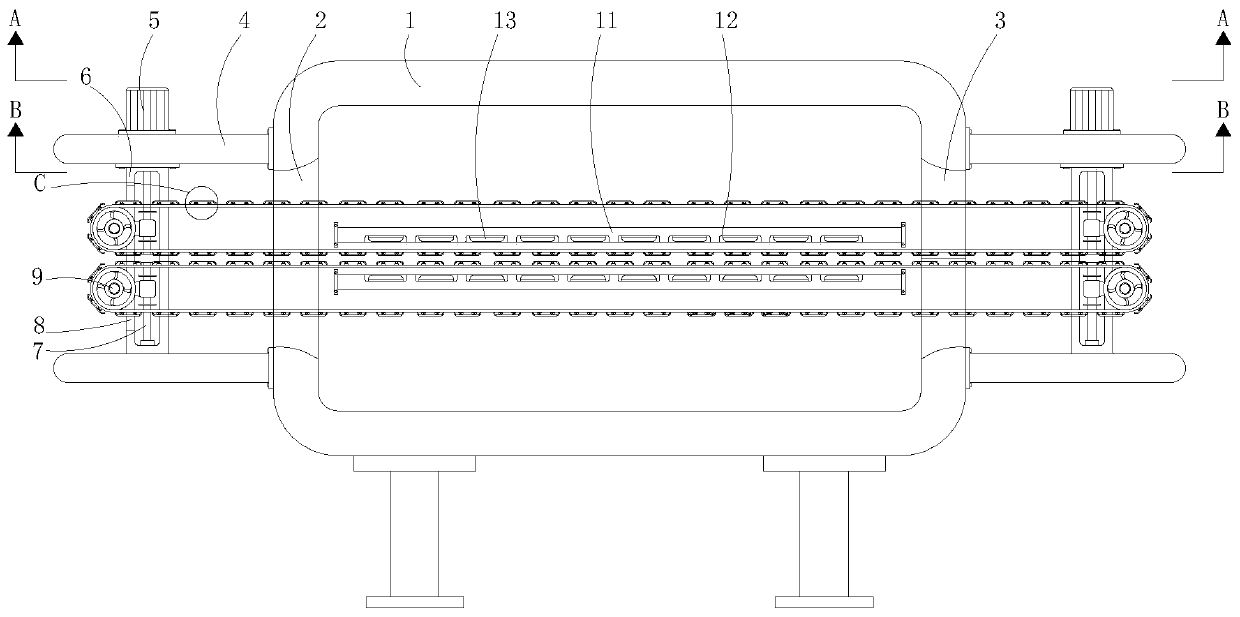

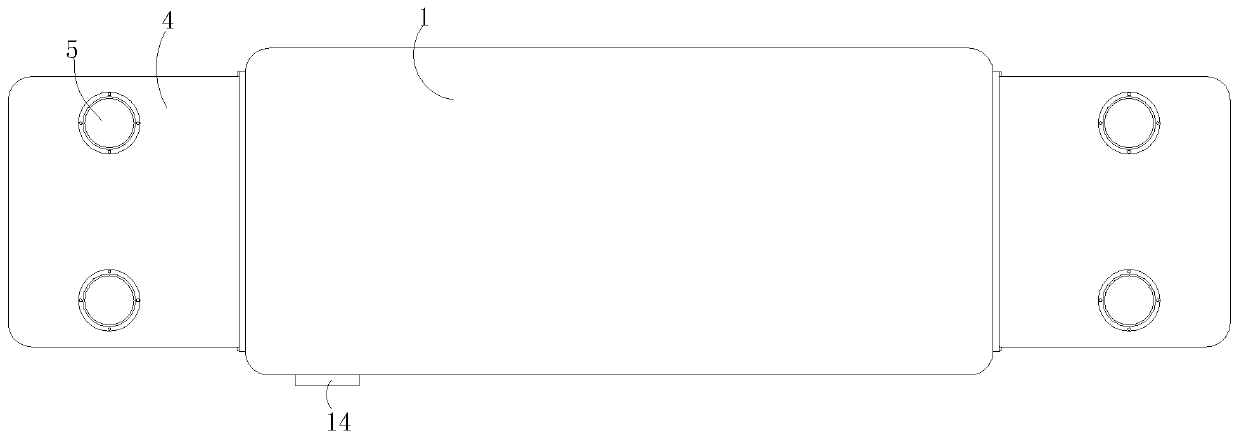

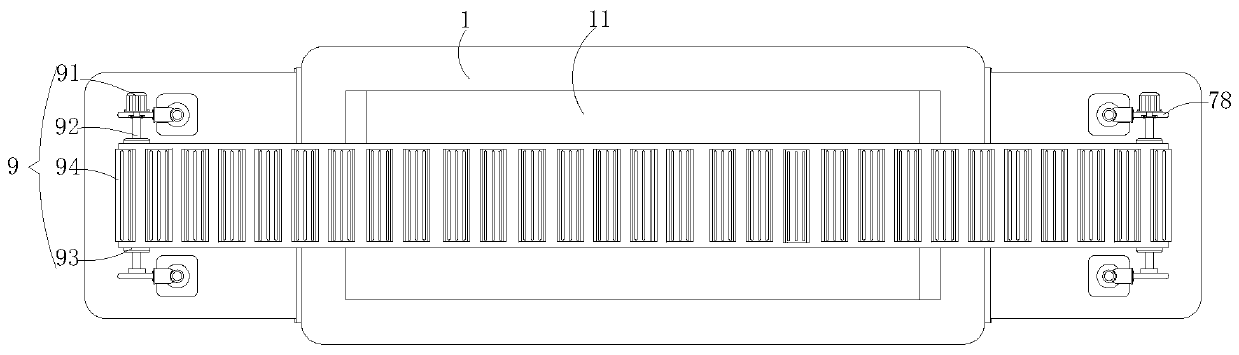

[0024] Such as Figure 1-6As shown, the present invention provides a technical solution: a hot rolling equipment for aluminum foam sandwich panels, including a machine body 1, a material guide port 2, a discharge port 3, two mounting frames 4, four synchronous motors 5, Four vertical installation cylinders 6, four symmetrical adjustment mechanisms 7, four vertical movable slots 8, two transmission mechanisms 9, contact pressing mechanism 10, two built-in plates 11, installation groove 12, heater 13 and control panel 14, The material guide port 2 and the discharge port 3 are set on the left and right sides of the machine body 1 respectively, two installation frames 4 are respectively installed at the material guide port 2 and the discharge port 3, and the four synchronous end machines 5 are installed in groups of two. On the top of the two mounting frames 4, four vertical mounting tubes 6 are symmetrically installed in two groups on the inner sides of the two mounting frames 4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com