Organic solvent purification device and method

A technology for organic solvents and low-boiling point solvents, applied in the field of organic solvent purification devices, can solve the problems of environmental protection and high energy consumption, and achieve the effects of improving recovery rate and purity, energy saving and environmental protection, and simple and effective methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

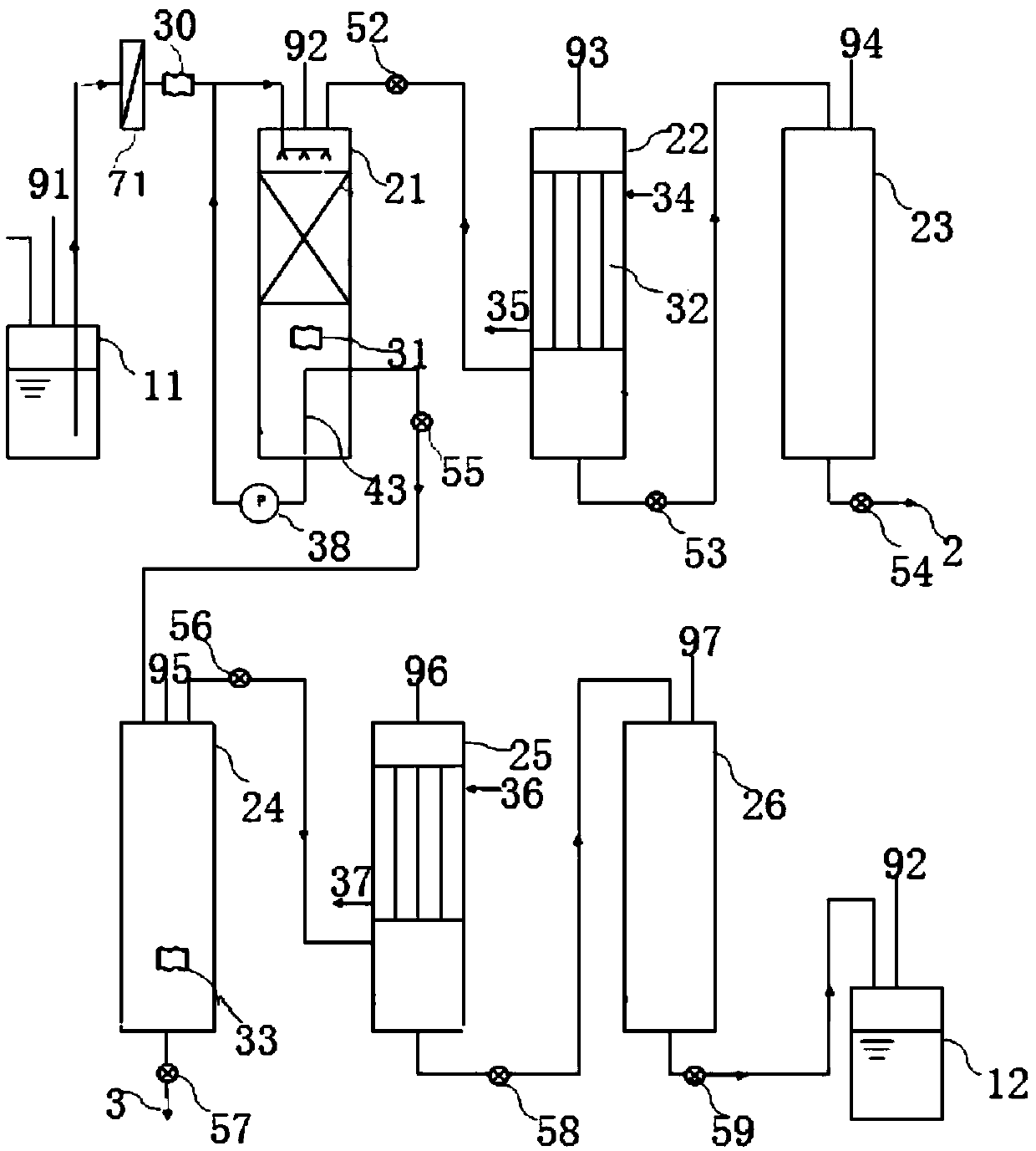

[0030] Such as figure 1 As shown, this embodiment discloses a purification device for organic solvents, including a low boiling point solvent separator 21 under vacuum conditions, a first cooler 22, a first relay tank 23, a high boiling point and residue separator 24 , the second cooler 25, the second relay tank 26;

[0031] The upper section and the lower section of the low boiling point solvent separator 21 are respectively communicated with the first cooler 22 and the high boiler and residue separator 24;

[0032] The lower section of the first cooler 22 communicates with the first relay tank 23;

[0033] The upper section of the high boiling point and residue separator 24 communicates with the second cooler 25 , and the lower section of the second cooler 25 communicates with the second relay tank 26 .

[0034] The discharge port at the lower end of the second relay tank 26 communicates with the finished product tank 12 .

[0035] The purification device also includes a ...

Embodiment 2

[0045] This embodiment discloses a method for separating an organic solvent using the organic solvent purification device described in Embodiment 1, comprising the following steps:

[0046] S1: remove the substances with lower boiling point in the organic solution through the low boiling point solvent separator and the first cooler to obtain the intermediate liquid;

[0047] S2: Remove substances with higher boiling points and metal ions in the intermediate liquid through the high boiling point and residue separator and the second cooler.

[0048]S0 is also included before S1: the raw waste liquid to be separated first enters the filter to obtain the filtered liquid, and the filtered liquid enters the preheater for preheating treatment.

[0049] S1 specifically includes the following steps: the low boiling point substance is heated and evaporated, enters the first cooler through the pipe in the form of steam, the ice water cooled by the first cooler becomes liquid, and the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com