Liquid-swellable alginate chitosan composite fiber, preparation method and application thereof

An alginate and composite fiber technology, applied in the direction of alginate rayon, fiber chemical characteristics, absorption pads, etc., can solve the problems of affecting wound healing, slow absorption, poor bacteriostatic and sterilizing effect, etc. Growth of fungi and bacteria, high fluid absorption, and fast wound healing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

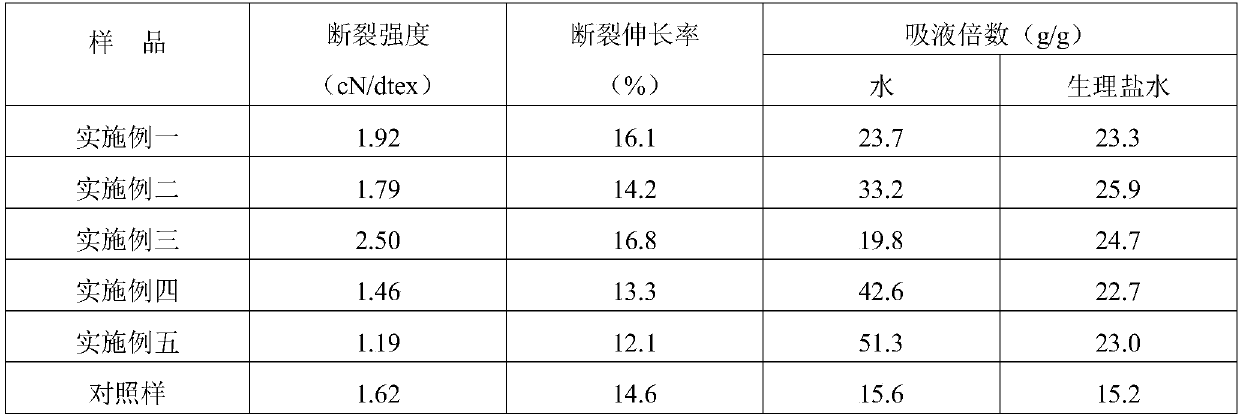

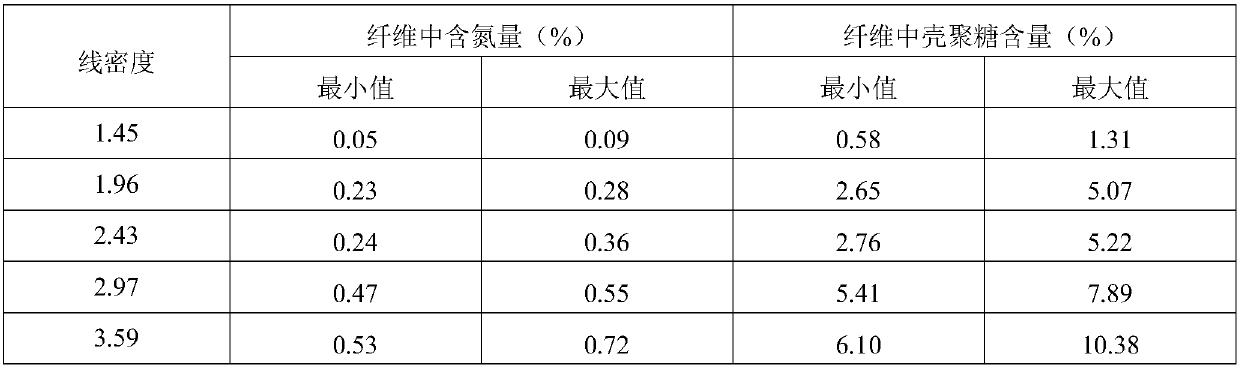

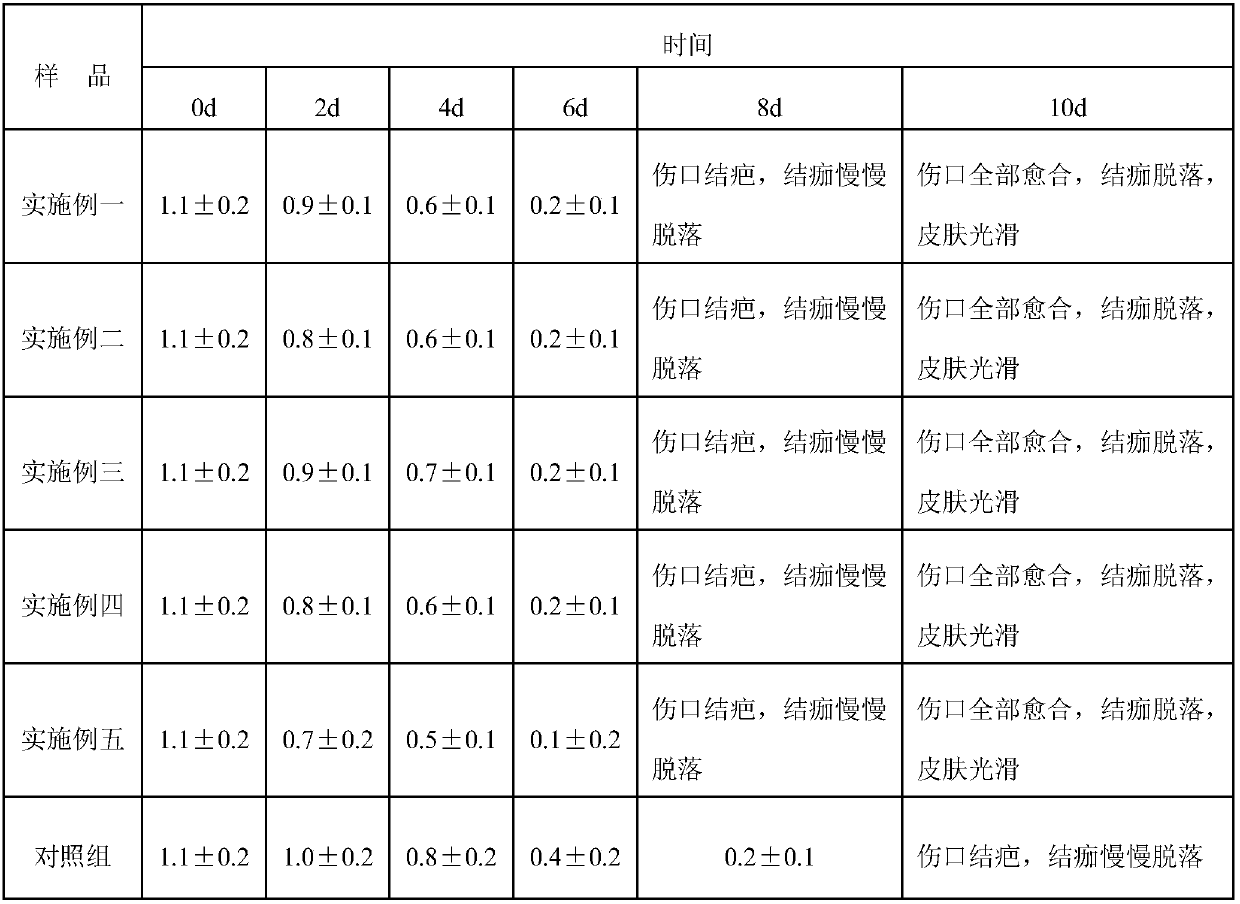

Examples

preparation example Construction

[0028] A kind of preparation method of the alginate-chitosan composite fiber of liquid absorption swelling of the present invention, comprises the following steps:

[0029] 1) Take calcium chloride aqueous solution or calcium ion slow-release system, add chitosan oligosaccharide, stir, adjust the pH value to make the pH value 4.5-6.2, add grass coral extract, peppermint extract, hyaluronic acid and borneol, mix well, get coagulation bath;

[0030] 2) Take alginate, add it into deionized water, stir at 20-25°C for 4-6 hours, filter, stand for defoaming, and stand for 24-48 hours to obtain alginate solution;

[0031] 3) Spray the alginate solution obtained in step 2) into the coagulation bath obtained in step 1) through a spinneret, the temperature of the coagulation bath is 15-25°C, stretching, washing with water, and drying to obtain alginate chitosan Composite fibers.

[0032] Preferably, deionized water is used for washing in step 3), and the temperature of the deionized w...

Embodiment 1

[0036] A kind of preparation method of the alginate-chitosan composite fiber of liquid absorption swelling of the present invention, comprises the following steps:

[0037] 1) Preparation of coagulation bath

[0038] Take calcium chloride, dissolve it in deionized water, and make a calcium chloride aqueous solution with a concentration of 1.10% w / v (g / mL), add chitosan oligosaccharide, stir, add an appropriate amount of dilute hydrochloric acid solution, and adjust the pH value , so that the pH value is 4.98, add grass coral extract, peppermint extract and hyaluronic acid, stir, mix well, and get a coagulation bath;

[0039] The addition of chitosan oligosaccharide is 5% w / v (g / mL) of the volume of deionized water, and the addition of the grass coral extract is 0.5% w / v (g / mL) of the volume of deionized water , the addition of peppermint extract is 0.6% w / v (g / mL) of the volume of deionized water, and the addition of hyaluronic acid is 0.6% w / v (g / mL) of the volume of deioniz...

Embodiment 2

[0045] A kind of preparation method of the alginate-chitosan composite fiber of liquid absorption swelling of the present invention, comprises the following steps:

[0046] 1) Preparation of coagulation bath

[0047] Get calcium gluconate, be dissolved in deionized water, make the calcium gluconate solution that concentration is 0.8%w / v (g / mL), add chitosan oligosaccharide, stir, add appropriate acetic acid solution, adjust pH value, Make the pH value 5.1, add grass coral extract, hyaluronic acid and borneol to get a coagulation bath;

[0048] The addition amount of chitosan oligosaccharide is 2% w / v (g / mL) of the volume of deionized water, and the addition amount of grass coral extract is 1% w / v (g / mL) of the volume of deionized water , the addition of hyaluronic acid is 0.1% w / v (g / mL) of the volume of deionized water, and the addition of borneol is 0.7% w / v (g / mL) of the volume of deionized water;

[0049] The preparation method of oligo-chitosan is: get the chitosan of d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Absorptive capacity | aaaaa | aaaaa |

| Absorptive capacity | aaaaa | aaaaa |

| Water absorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com