Preparation method of whole wheat flour

A technology of whole wheat flour and wheat kernel flour, which is applied in the field of grain processing, can solve the problems of shortening the storage time of whole wheat flour, weakening the flavor of wheat, and lowering the quality of whole wheat flour products, so as to achieve easy quality and stability control and prevent the loss of nutrients , the effect of inhibiting fat oxidation and rancidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

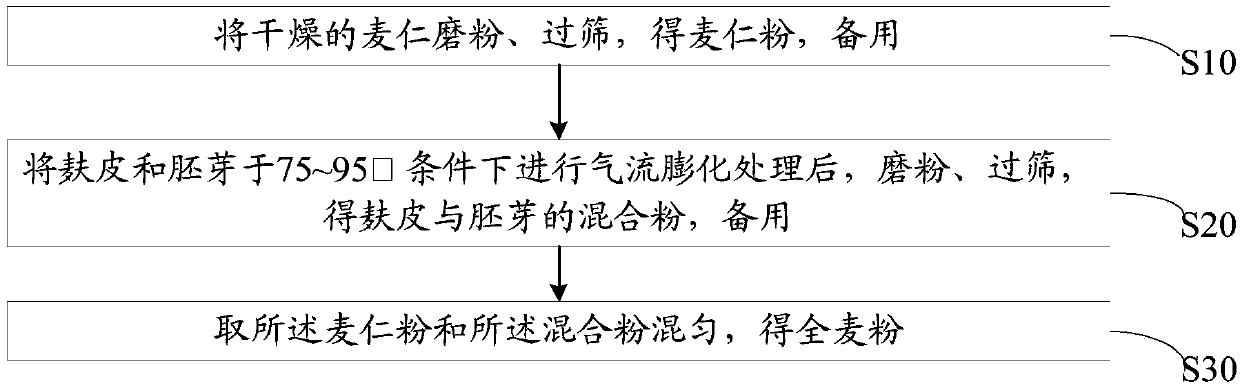

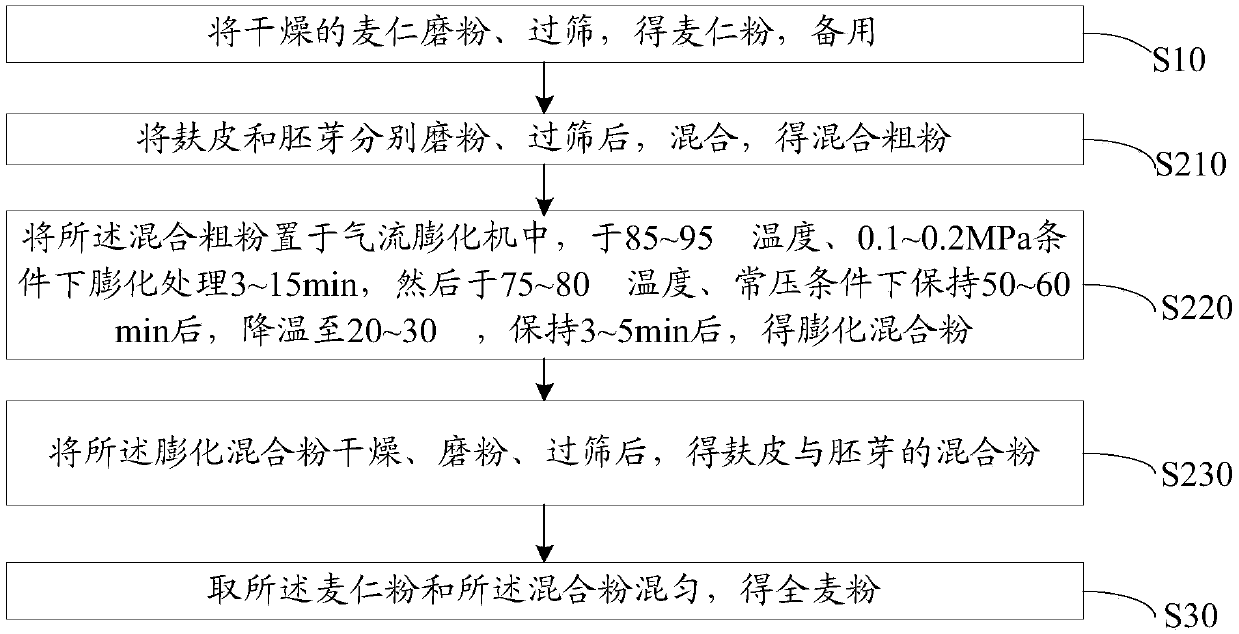

[0027] In view of this, the present invention proposes a kind of preparation method of whole wheat flour, combines figure 1 The schematic flow chart of the preparation method of whole wheat flour shown, the preparation method of described whole wheat flour comprises the following steps:

[0028] Step S10: Grinding and sieving the dried wheat kernels to obtain wheat kernel powder for later use.

[0029] Wherein, during the sieving, pass through a 80-100 mesh sieve.

[0030] Wheat kernel flour is the main component of whole wheat flour. In order to improve the taste and quality of whole wheat flour, it is necessary to filter out the wheat kernel flour with a suitable particle size range after the pre-treated dry wheat kernel is superfinely ground as the preparation of whole wheat flour. raw material. In this example, the process of screening wheat kernel flour with a suitable particle size range is achieved by passing through a 80-100 mesh sieve, which is in line with GB-T 140...

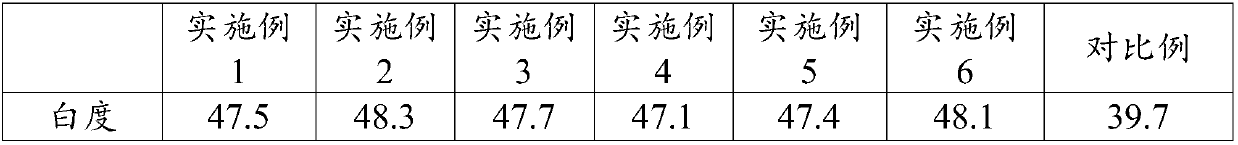

Embodiment 1

[0050] Grind the dried wheat kernels and pass through an 80-mesh sieve to obtain wheat kernel powder, which is set aside.

[0051] Grind the bran and germ separately, pass through a 60-mesh sieve, and mix according to the weight ratio of 1:0.125 to obtain mixed coarse powder, and spread the mixed coarse powder evenly on the tray, and place it on the steel wire of the expansion tank of the air-flow extruder. On the sieve, turn on the steam generator and air compressor until the conditions in the tank reach 85°C and 0.1MPa. After keeping it for 15 minutes, open the condensation system and release the pressure until the condition in the tank reaches 76°C and normal pressure, and keep it under this condition for 50 minutes (perform dehumidification treatment every 15 minutes during this period). Then cool down to 20°C, keep for 5 minutes, take out the puffed mixed powder and grind it, pass through a 90-mesh sieve to get the mixed powder, and set aside.

[0052] Take 100g of the a...

Embodiment 2

[0054] The dried wheat kernels are ground and passed through a 90-mesh sieve to obtain wheat kernel powder, which is set aside.

[0055] Grind the bran and germ separately, pass through a 70-mesh sieve, and mix according to the weight ratio of 1:0.15 to obtain the mixed coarse powder, and spread the mixed coarse powder evenly on the tray, and place it on the steel wire of the expansion tank of the air-flow extruder. On the sieve, turn on the steam generator and air compressor until the conditions in the tank reach 88°C and 0.15MPa. After keeping it for 10 minutes, open the condensing system and release the pressure until the condition in the tank reaches 80°C and normal pressure, and keep it under this condition for 60 minutes (during this period, dehumidification treatment is performed every 20 minutes). Then cool down to 22°C, keep for 3 minutes, take out the puffed mixed powder and grind it, pass through a 100-mesh sieve to get the mixed powder, and set aside.

[0056] Tak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com