A recyclable preparation method of microporous iron-nitrogen doped carbon catalyst material

A nitrogen-doped carbon, cyclic preparation technology, applied in structural parts, electrical components, battery electrodes, etc., can solve the problems of increasing production and processing complexity, large size, and sparse micro-mesoporous pores, to improve catalytic performance and current. The effect of density, mild experimental conditions, and simple synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

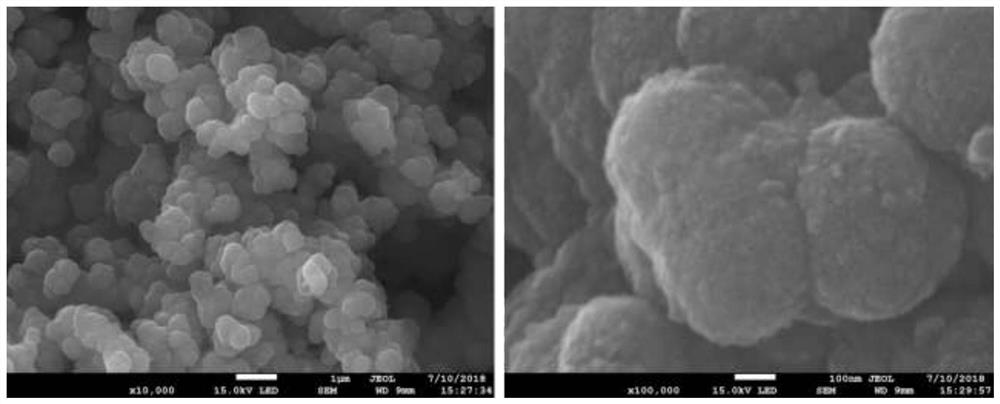

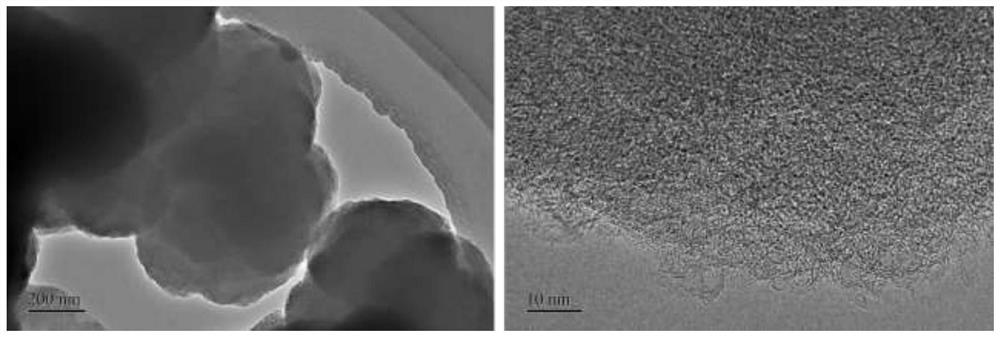

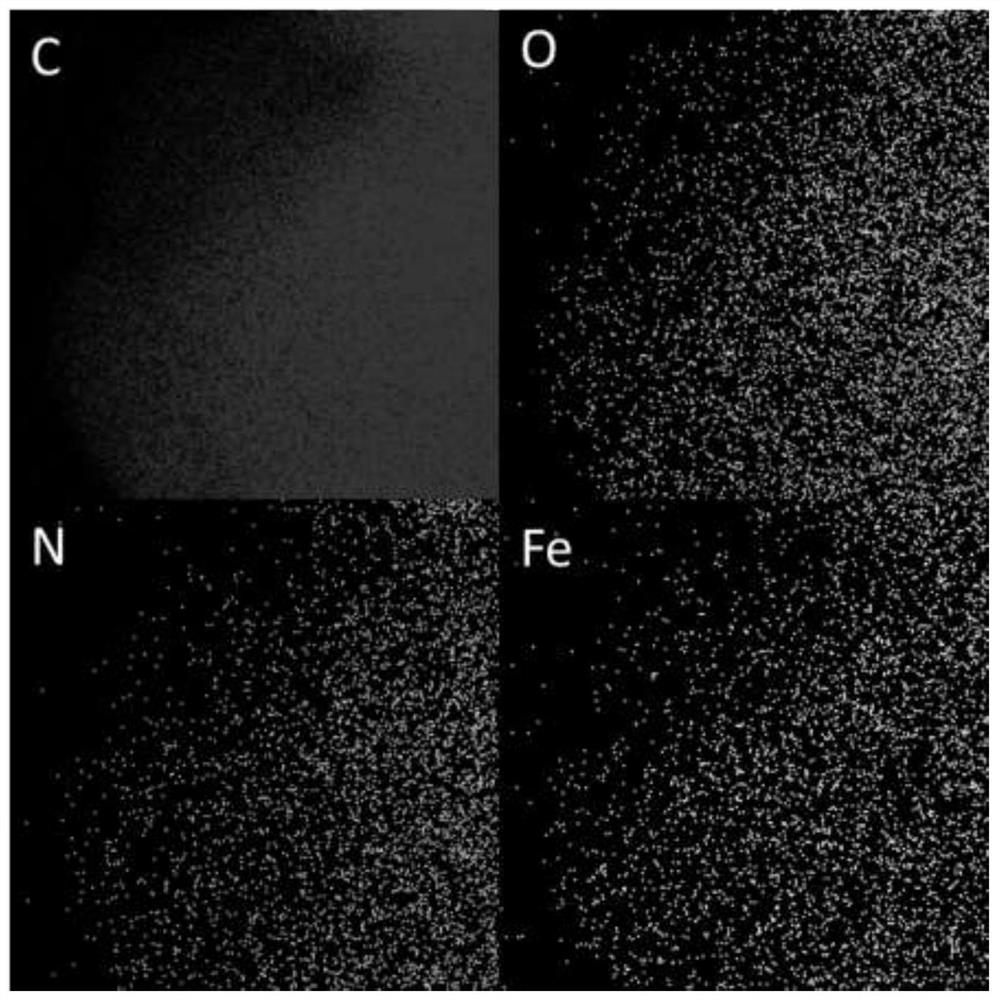

Image

Examples

Embodiment 1

[0034] It is weighed 4.97 g of hexahydroform chloride, and stirred in 38 ml of water and dissolved 40 ml of ferric chloride solution, stirred at room temperature for 0.5 hours, rapid addition of 0.2 ml of pyrrole liquid, pyrrole monomer concentration of 0.2 mol / L; continued at room temperature 5 After an hour, a polypyrrol precursor having a iron ion was obtained by filtration (Fe ions / PPY ① ) And iron ion filtrate ① Will FE ions / PPY ① After mixing with 5 g of zinc chloride and 15 ml of water, it is placed in a 60 ° C blast drying oven to dry the Zinc chloride outsourcing. ions / PPY ① Precurable body (ZnCl 2 / Fe ions PPY ① );

[0035] Will dry the ZnCl 2 / Fe ions / PPY ① In the tubular furnace, after 0.5 hours of 5 ° C / min, the heating rate was raised to 900 ° C at a heating rate of 5 ° C / min, and the carbide product was cooled.

[0036] The carbide was polished into a powder, adding 20 ml, 1 mol / L hydrochloric acid, 1 hour, to obtain microporous iron-nitrogen dopin...

Embodiment 2

[0045] About 38ml iron ion filtrate collected in Example 1 ① 1 ml, 30% by weight of hydrogen oxygen was added, stirred for 0.5 hours, rapidly added 0.55 ml of pyrrole liquid, and stirred at room temperature for 5 hours, and the polypyrrol precursor having iron ions were obtained by filtration (Fe ions / PPY ② ) And iron ion filtrate ② ;

[0046] Put feet ions / PPY ② After mixing with 5 g of zinc chloride and 15 ml of water, it is placed in a 60 ° C blast drying oven to dry the Zinc chloride outsourcing. ions / PPY ② Precurable body (ZnCl 2 / Fe ions / PPY ② );

[0047] Will dry the ZnCl 2 / Fe ions / PPY ② In the tubular furnace, after 0.5 hours of 5 ° C / min, the heating rate was raised to 900 ° C at a heating rate of 5 ° C / min, and the carbide product was cooled.

[0048] Grasite the carbide into powder, add hydrochloride ① Ultrasound 1 hour, the microporous iron-nitrogen doping carbon is obtained by filtration. ② Hydrochloric acid ② After the product is buckled with water 2...

Embodiment 3

[0050] About 36ml iron ion filtrate collected in Example 2 ② 1 ml, 30% by weight of hydrogen oxygen was added, stirred for 0.5 hours, rapidly added 0.55 ml of pyrrole liquid, and stirred at room temperature for 5 hours, and the polypyrrol precursor having iron ions were obtained by filtration (Fe ions / PPY ③ ) And iron ion filtrate ③ ;

[0051] Put feet ions / PPY ③ After mixing with 5 g of zinc chloride and 15 ml of water, it is placed in a 60 ° C blast drying oven to dry the Zinc chloride outsourcing. ions / PPY ③ Precurable body (ZnCl 2 / Fe ions / PPY ③ );

[0052] Will dry the ZnCl 2 / Fe ions / PPY ③ In the tubular furnace, after 0.5 hours of 5 ° C / min, the heating rate was raised to 900 ° C at a heating rate of 5 ° C / min, and the carbide product was cooled.

[0053] Grasite the carbide into powder, add hydrochloride ② Ultrasound 1 hour, the microporous iron-nitrogen doping carbon is obtained by filtration. ③ Hydrochloric acid ③ After the product is buckled with water 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com