Multi-channel current collecting system with wide temperature range and high precision

An acquisition system and high-precision technology, applied in the direction of measurement using digital measurement technology, can solve the problems of rough and inaccurate acquisition methods, and achieve the effects of light weight, high current accuracy, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

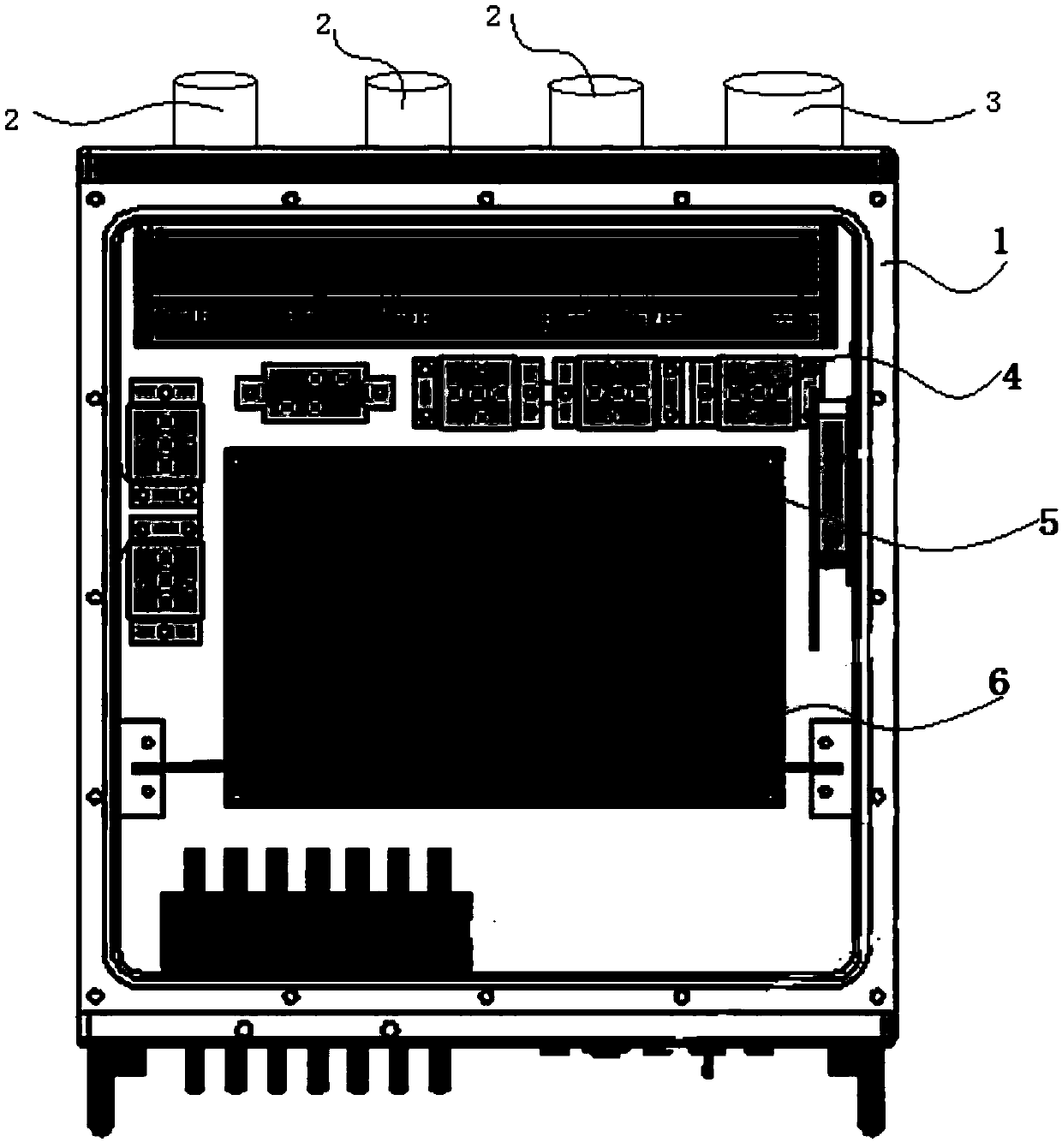

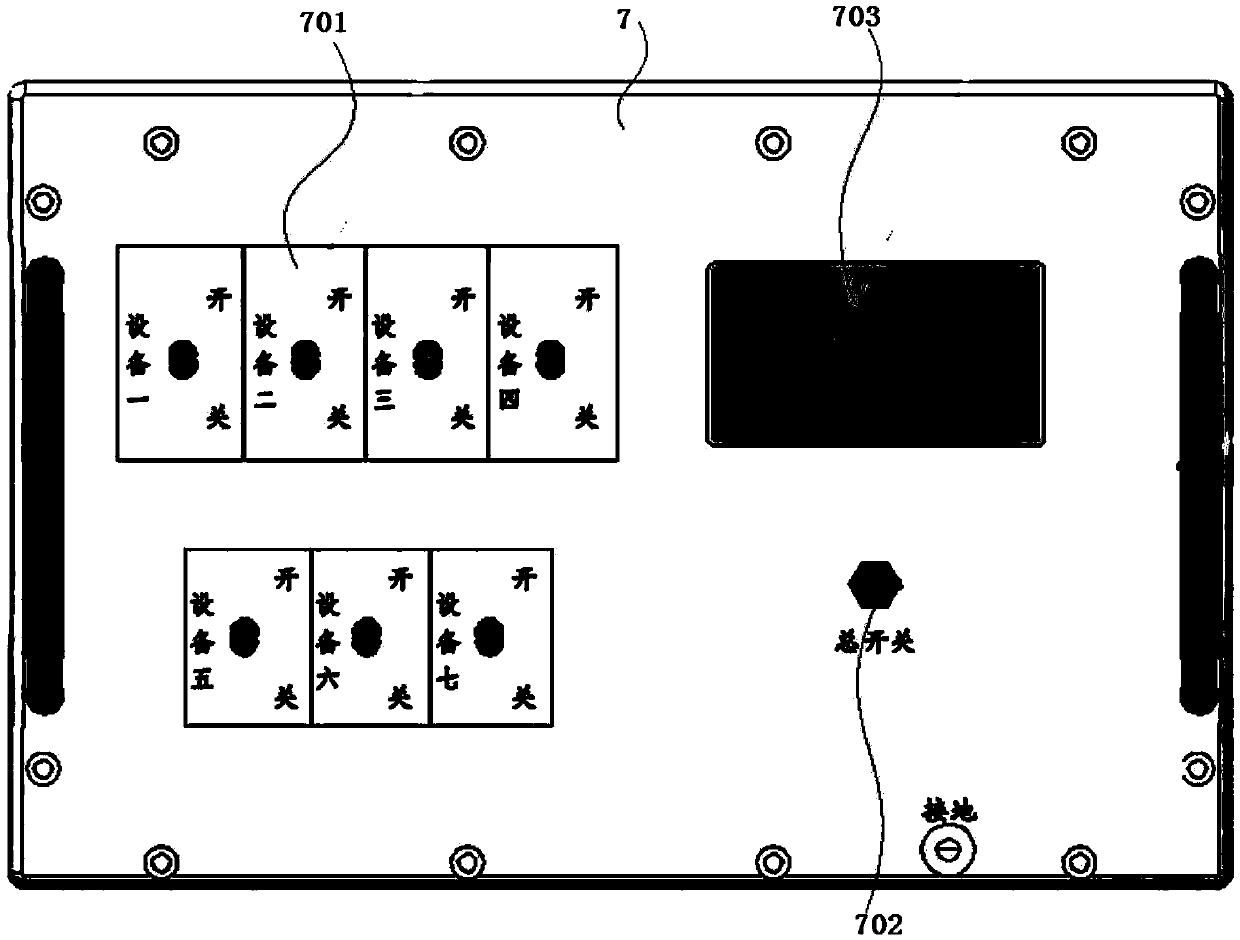

[0059] see Figure 1 to Figure 3 , Wide-temperature high-precision multi-channel current acquisition system, mainly includes a housing 1, a power input socket 2, an output socket 3, a relay 4, n sensing modules 5, a control circuit board 6 and a front panel 7. n=7.

[0060] The housing 1 is a box, and the six outer surfaces are respectively marked as a first side wall, a second side wall, a third side wall, a fourth side wall, a fifth side wall and a sixth side wall. And the first side wall is opposite to the third side wall, the second side wall is opposite to the fourth side wall, and the fifth side wall is opposite to the sixth side wall.

[0061] The power input socket 2 and the output socket 3 are arranged on the first side wall of the casing 1 .

[0062] The power input socket 2 is connected to the power supply, and the current of the power supply flows through the relay 4 and n sensing modules 5 and then is output to the external device through the output socket 3 . ...

Embodiment 2

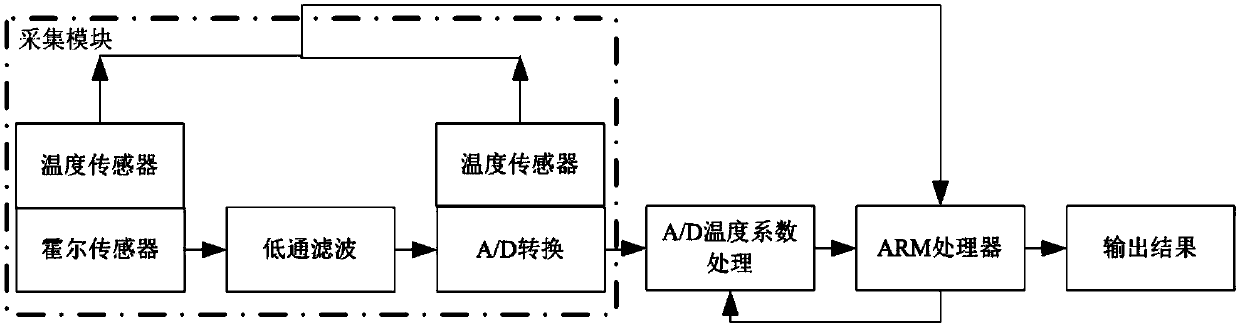

[0124] see Figure 4 , the circuit structure of the wide-temperature high-precision multi-channel current acquisition system is as follows:

[0125] The input current is input into 7 external devices through 7 input switches, and the input current is respectively recorded as I1, I2, I3, I4, I5, I6 and I7.

[0126] The 7 sensing modules respectively measure the voltage values and corresponding temperature values of 7 external devices.

[0127] The voltage values are respectively recorded as Vin1, Vin2, Vin3, Vin4, Vin5, Vin6 and Vin7.

[0128] The temperature values are recorded as t1, t2, t3, t4, t5, t6 and t7, respectively.

[0129] The voltage Vin1 flows through the resistor R1. Voltage Vin2 flows through resistor R2. Voltage Vin3 flows through resistor R3. Voltage Vin4 flows through resistor R4. Voltage Vin5 flows through resistor R5. Voltage Vin6 flows through resistor R6. Voltage Vin7 flows through resistor R7.

[0130] The resistor R1 and the capacitor C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com