Method for evaluating gas wettability effect by using core flooding experiment

A technology of core displacement and gas wettability, which is applied in the direction of material inspection and soil material testing, can solve the problems that the gas-liquid two-phase seepage in the formation cannot be truly simulated, and the core effect cannot be truly reflected, and the test results are simple. Intuitive, simple and easy method, widely applicable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

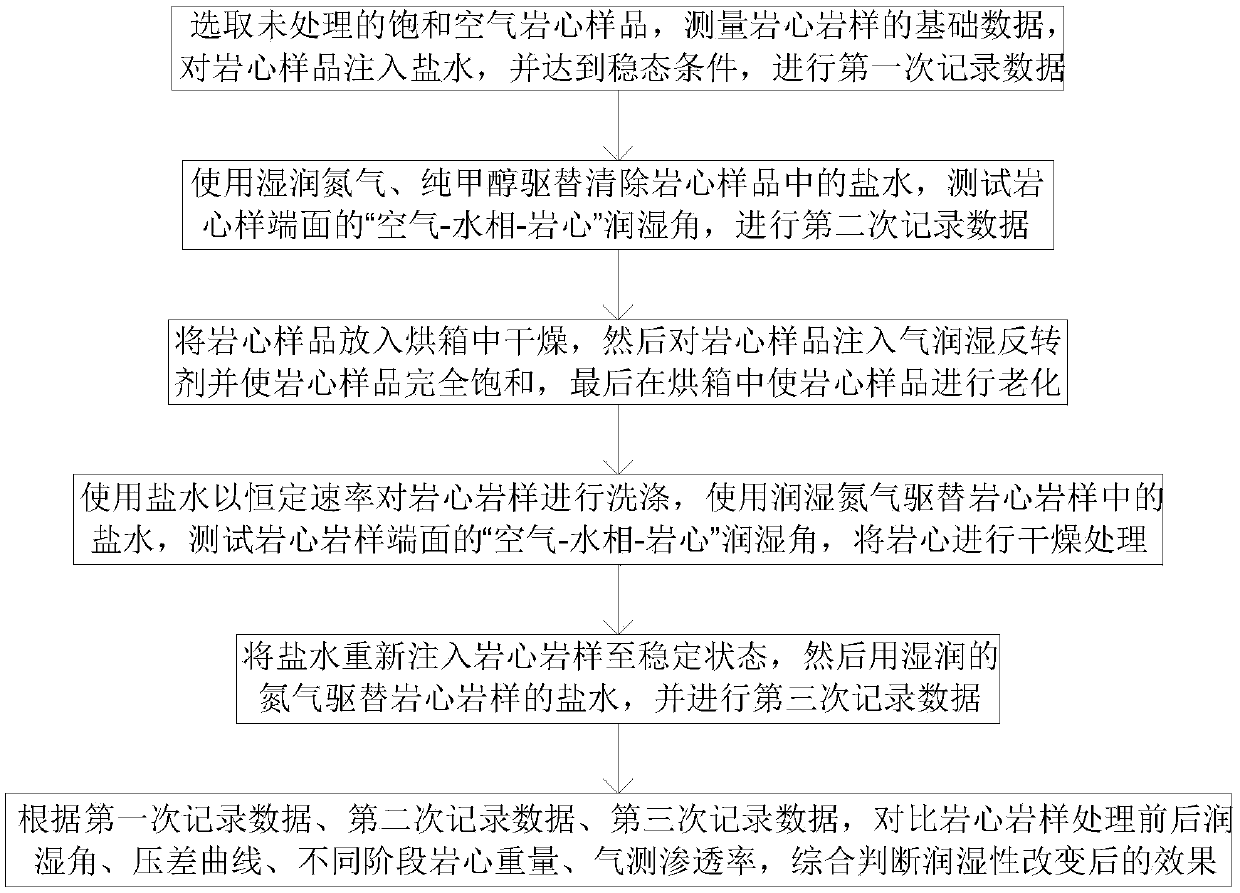

Method used

Image

Examples

Embodiment

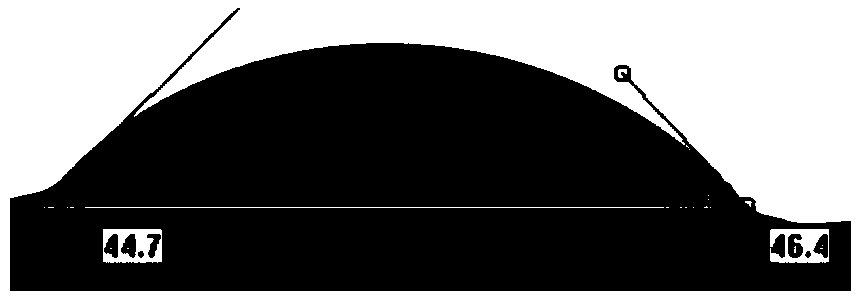

[0056] The length of rock sample 1 is selected as 3.516cm, the diameter is 2.492cm, the gas permeability is 0.6328mD, and the porosity is 9.82%. figure 2 Shown is the wetting angle of rock sample 1 before treatment, such as image 3 As shown, it is the wetting angle after the treatment of rock sample 1. When θ1 Figure 4 Shown is the comparison chart of gas flooding flowback rate before and after treatment of rock sample 1, η 1 2 It shows that the chemical agent increases the gas moisture of the core and enhances the flowback rate; the gas permeability results of rock sample 1 at different stages before and after treatment are shown in Table 1:

[0057] Table 1 Gas permeability at different stages before and after treatment of rock sample 1

[0058] Gas permeability K of core rock samples g1

[0059] K g2 g3 , it indicates that the chemical agent increases the gas-humidity of the core, which is beneficial to the flow of the gas-flooding liquid phase; Figure 5 S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com