Pull rod type oil level monitoring device for oil storage cabinets

A monitoring device and oil conservator technology, which is used in measuring devices, lubrication indicating devices, liquid/fluid solids measurement, etc., can solve the problem that the connection between the float ball and the pendulum rod is easily damaged, affects the normal operation of the transformer, and the pendulum rod cannot swing normally. and other problems, to achieve the effect of good protection, simple structure and normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

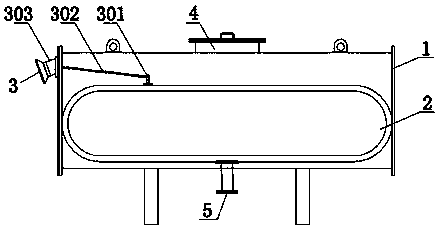

[0023] Embodiment 1, with reference to figure 1 with 2 , a pull rod type oil level monitoring device for an oil conservator, comprising an oil conservator 1, a transformer capsule 2, a first valve pipe 4 and a second valve pipe 5, the upper and lower ends of the oil conservator 1 are respectively welded with first The valve pipe 4 and the second valve pipe 5, the outer wall of the oil conservator 1 is sprayed with anti-static material, anti-static material polyethylene, which can strengthen the safety of the oil conservator 1, the top of the oil conservator 1 is left and right Both sides are welded with lifting lugs, which can facilitate the suspension of the oil conservator 1 during transportation. The inner cavity of the oil conservator 1 is clamped with a transformer capsule 2 along the left and right directions. The left top of the oil conservator 1 One end of the monitoring mechanism is clamped, and the other end of the monitoring mechanism 3 extends into the inner cavit...

Embodiment 2

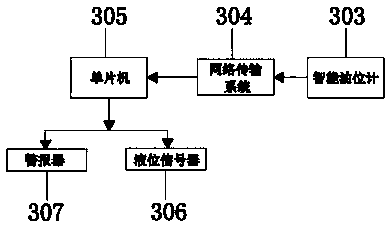

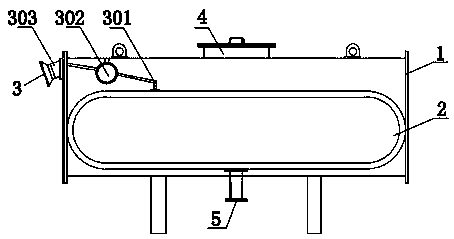

[0026] Embodiment 2, with reference to image 3 , 4 and 5, a pull rod type oil level monitoring device for an oil conservator, comprising an oil conservator 1, a transformer capsule 2, a first valve pipe 4 and a second valve pipe 5, the upper and lower ends of the oil conservator 1 are respectively welded with The first valve pipe 4 and the second valve pipe 5, the outer wall of the oil conservator 1 is sprayed with antistatic material, antistatic material polyethylene, which can enhance the safety of the oil conservator 1, the oil conservator 1 Lifting lugs are welded on the left and right sides of the top, through which the oil conservator 1 can be hung during transportation. One end of the monitoring mechanism is clamped on the top of the side, and the other end of the monitoring mechanism 3 extends into the inner cavity of the oil conservator 1 and is clamped with the transformer capsule 2. The monitoring mechanism 3 includes a cylindrical box 302, and the cylindrical box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com