Vacuum arc propeller based on multi-anode structure

A multi-anode and thruster technology, which is applied in the direction of thrust reverser, machine/engine, and plasma utilization, can solve the problems of increasing the mass and volume of the thruster, unfavorable vacuum arc thruster application, increasing the mass and volume of the thruster, etc. , to improve propulsion performance, achieve long-gap vacuum breakdown, and reduce radial diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] An embodiment of the present invention provides a vacuum arc thruster based on a multi-anode structure, which improves the propulsion performance of the vacuum arc thruster through a unique anode structure setting and a vacuum gap breakdown discharge mechanism.

[0059] A vacuum arc thruster based on a multi-anode structure provided by an embodiment of the present invention adopts a vacuum gap breakdown discharge mechanism. The discharge mechanism is field-induced electron emission near the cathode caused by a strong electric field. The explosion, the generated plasma is generally called metal plasma, which is mainly composed of metal ions and electrons.

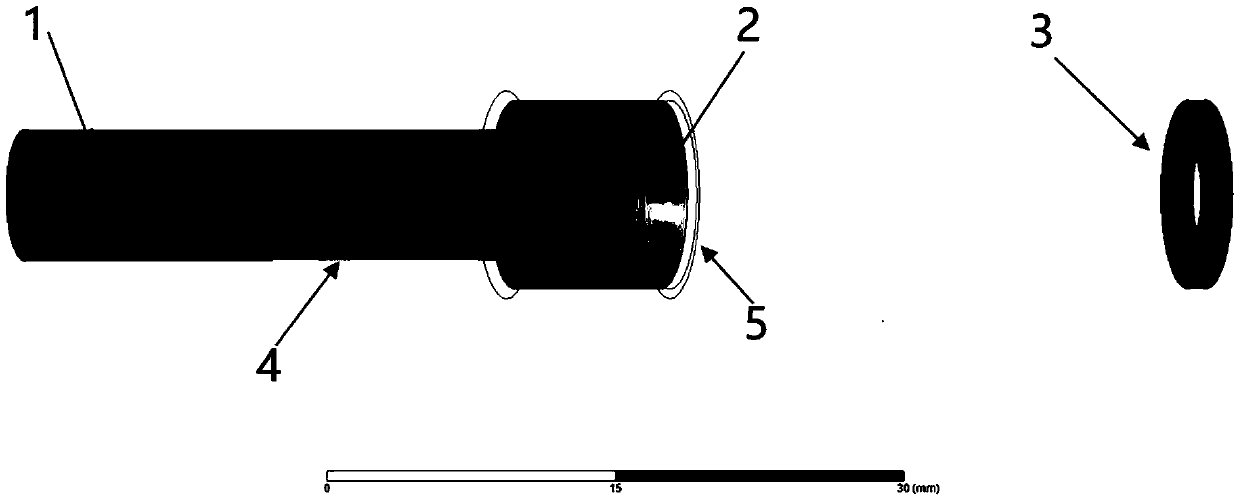

[0060] A schematic structural diagram of a vacuum arc thruster based on a multi-anode structure provided by an embodiment of the present invention is as follows figure 1 As shown, the vacuum arc thruster is a coaxial electrode structure, including: a cathode structure 1, a multi-anode structure (2, 3) and an insulatin...

Embodiment 2

[0089] This embodiment provides an experimental system of a vacuum arc thruster based on a multi-anode structure, and performs experimental verification of the vacuum arc thruster proposed by the present invention. The realization structure of the experimental system is as follows figure 2 As shown, the specific contents may include the following:

[0090] An application system of a vacuum arc thruster based on a multi-anode structure includes: a pulse power supply, a vacuum discharge device and a diagnosis system.

[0091] Pulse power supplies use energy storage capacitors as the energy source for discharge. Before discharging, the energy storage capacitor C is charged to a specific voltage. When the switch SG is closed, the voltage of the capacitor C starts to be applied to both ends of the electrodes through the current limiting resistor R1 and the inductor L. Therefore, a discharge occurs due to breakdown of the vacuum gap. The diode D connected in series with the circ...

Embodiment 3

[0116] This embodiment provides a vacuum arc thruster based on a multi-anode structure, and compares the influence of the distance between the cathode structure and the remote anode (abbreviated as D) on the discharge characteristics of the multi-anode electrode structure. The specific comparison results are as follows:

[0117] Under the same voltage, when D is 100mm, 80mm, 60mm, and 40mm respectively, according to the value of D and the time when the inter-electrode voltage drops to the arc voltage, the propagation velocity of the plasma can be calculated as: 6.38km / s, 6.24km / s, 6.22km / s, 6.02km / s.

[0118] According to the electric field simulation, when D is 100mm, 80mm, 60mm, and 40mm respectively, the initial positions of the cathode structure from the A area are: 25.64mm, 25.81mm, 23.48mm, and 18mm, respectively. Assuming that the velocity of the metal plasma remains constant during propagation, the durations of T1 are: 4.02 μs, 4.14 μs, 3.95 μs, and 2.96 μs, respective...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cone angle | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com