Waterborne polyurethane coating agent and preparation method thereof

A water-based polyurethane and finishing agent technology, which is applied in textiles and papermaking, can solve the problems of water-based polyurethane finishing agents such as easy yellowing, achieve excellent ultraviolet reflection, avoid deterioration, and improve dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

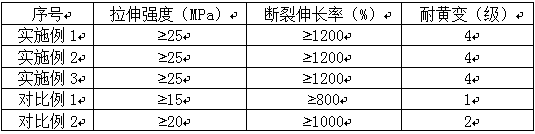

Examples

Embodiment 1

[0029] A water-based polyurethane finishing agent, which is composed of the following components in parts by weight: 90 parts of water-based polyurethane prepolymer, 45 parts of spirulina small molecule peptide, 50 parts of deionized water, and 5 parts of hyperbranched cationic polyacrylamide.

[0030] The preparation method of above-mentioned aqueous polyurethane prepolymer, it may further comprise the steps:

[0031] (1) Weigh the following raw materials in parts by weight: 80 parts of polymer polyol, 50 parts of acetone, 15 parts of hydrophilic chain extender, 10 parts of neutralizing agent, 3 parts of polyaspartic acid ester, modified nano titanium dioxide 30 parts, 40 parts of isocyanate; Described polymer polyol is polyester polyol or polyether polyol; Described isocyanate is toluene diisocyanate, diphenylmethane diisocyanate, polymethylene polyphenyl polyol One or more mixtures of isocyanates; the hydrophilic chain extender is one or more mixtures of dimethylol propionic ...

Embodiment 2

[0040] A water-based polyurethane finishing agent, which is composed of the following components in parts by weight: 80 parts of water-based polyurethane prepolymer, 40 parts of spirulina small molecule peptide, 40 parts of deionized water, and 4 parts of hyperbranched cationic polyacrylamide.

[0041] The preparation method of above-mentioned aqueous polyurethane prepolymer, it may further comprise the steps:

[0042] (1) Weigh the following raw materials in parts by weight: 60 parts of polymer polyol, 40 parts of acetone, 5 parts of hydrophilic chain extender, 20 parts of neutralizing agent, 2 parts of polyaspartic acid ester, modified nano titanium dioxide 15 parts, 60 parts of isocyanate; Described polymer polyol is polyester polyol or polyether polyol; Described isocyanate is toluene diisocyanate, diphenylmethane diisocyanate, polymethylene polyphenyl polyol One or more mixtures of isocyanates; the hydrophilic chain extender is one or more mixtures of dimethylol propionic...

Embodiment 3

[0051] A water-based polyurethane finishing agent, which is composed of the following components in parts by weight: 100 parts of water-based polyurethane prepolymer, 50 parts of spirulina small molecule peptide, 30 parts of deionized water, and 3 parts of hyperbranched cationic polyacrylamide.

[0052] The preparation method of above-mentioned aqueous polyurethane prepolymer, it may further comprise the steps:

[0053] (1) Weigh the following raw materials in parts by weight: 90 parts of polymer polyol, 60 parts of acetone, 30 parts of hydrophilic chain extender, 5 parts of neutralizing agent, 1 part of polyaspartic acid ester, modified nano titanium dioxide 5 parts, 20 parts of isocyanate; Described polymer polyol is polyester polyol or polyether polyol; Described isocyanate is toluene diisocyanate, diphenylmethane diisocyanate, multiple methylene polyphenyl polyol One or more mixtures of isocyanates; the hydrophilic chain extender is one or more mixtures of dimethylol propi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com