Regenerated cellulose fibers containing ceramide micro-capsules and preparation method of regenerated cellulose fibers

A technology of regenerated cellulose and ceramide, applied in the field of textiles, can solve the problems of destroying the physical and chemical properties of aloe vera gel, not being able to obtain the effect of skin care and moisturizing, and affecting the performance of aloe viscose fiber, so as to enhance the effect of isolation protection and promote Epidermal cell division and the effect of preventing the invasion of external stimuli

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Preparation of viscose spinning solution:

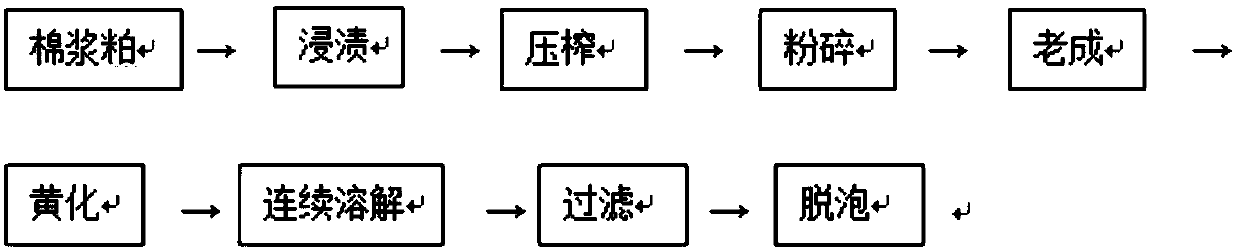

[0031] The raw material is cotton pulp with a degree of polymerization of 500-600, its methyl fiber content is greater than 90%, and according to figure 1 Process route shown Glue production:

[0032] The viscose spinning liquid methyl fiber content that is made according to above-mentioned process is 8.9%, and NaOH mass fraction is 6.0, and viscosity is (falling ball method) 59s, and maturity is (10%NH 4 Cl) 8.8 mL.

[0033] Falling ball method: the time required for a 2mm steel ball to fall 20cm from the viscose solution.

[0034] Preparation of microcapsules:

[0035] Prepare a mass fraction of 10% ceramide solution in reactor 1, the solvent is glycerin, and the mass fraction of emulsifier is 1%, stir evenly and let stand; prepare mass fraction in reactor 2 and be 5% ceramide solution, solvent It is water, the mass fraction of the emulsifier is 1%, and it is stirred evenly and then left to stand; the core material emu...

Embodiment 2

[0041] Preparation of viscose spinning solution:

[0042] The raw material is cotton pulp with a degree of polymerization of 500-600, its methyl fiber content is greater than 90%, and according to figure 1 Process route shown Glue production:

[0043] The viscose spinning liquid methyl fiber content that is made according to above-mentioned process is 8.9%, and NaOH mass fraction is 5.8, and viscosity is (falling ball method) 60s, degree of maturity is (10%NH 4 Cl) 8.7 mL.

[0044] Falling ball method: the time required for a 2mm steel ball to fall 20cm from the viscose solution.

[0045] Preparation of microcapsules:

[0046] Prepare mass fraction in reactor 1 and be 15% ceramide solution, solvent is glycerin, the mass fraction of emulsifier is 2%, after stirring evenly, let stand; Prepare mass fraction in reactor 2 and be 8% ceramide solution, solvent It is water, the mass fraction of the emulsifier is 1%, and it is stirred evenly and then left to stand; the core mater...

Embodiment 3

[0052] Preparation of viscose spinning solution:

[0053] The raw material is cotton pulp with a degree of polymerization of 500-600, its methyl fiber content is greater than 90%, and according to figure 1 Process route shown Glue production:

[0054] The viscose spinning solution made according to the above-mentioned process has a cellulose content of 8.9%, a NaOH mass fraction of 6.3, a viscosity of (falling ball method) 62s, and a degree of maturity of (10%NH 4 Cl) 8.9 mL.

[0055] Falling ball method: the time required for a 2mm steel ball to fall 20cm from the viscose solution.

[0056] Preparation of microcapsules

[0057] Prepare a ceramide solution with a mass fraction of 20% in the reactor 1, the solvent is glycerin, and the mass fraction of the emulsifier is 3%, stir evenly and let it stand; prepare a 10% ceramide solution in the reactor 2 with a solvent It is water, the mass fraction of the emulsifier is 3%, and it is stirred evenly and left to stand; the core...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com