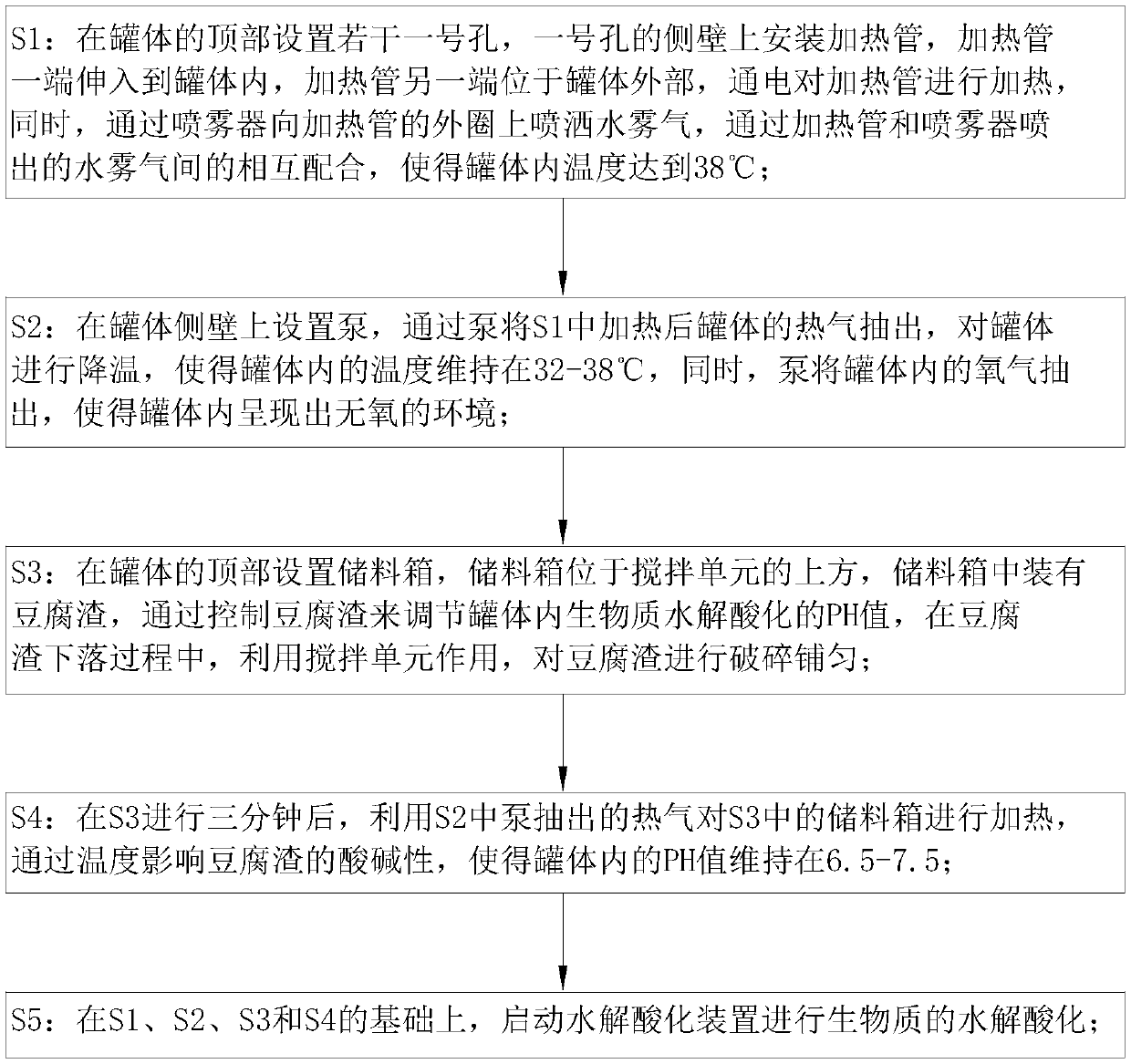

Biomass hydrolytic acidification process

A technology of hydrolysis, acidification and biomass, applied in waste fuel, fermentation and other directions, can solve the problem of slow hydrolysis and acidification of straw, and achieve the effect of increasing the crushing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

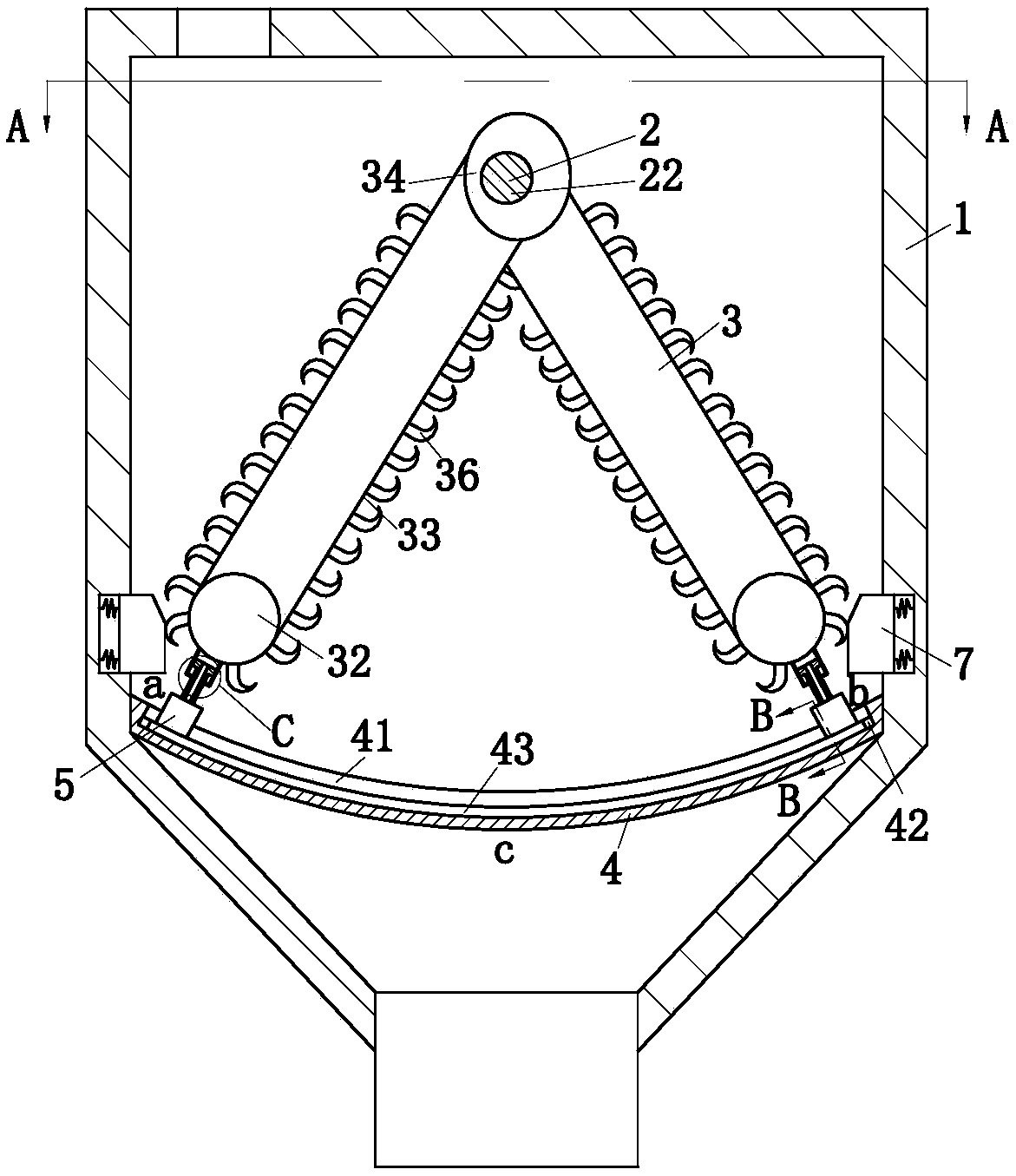

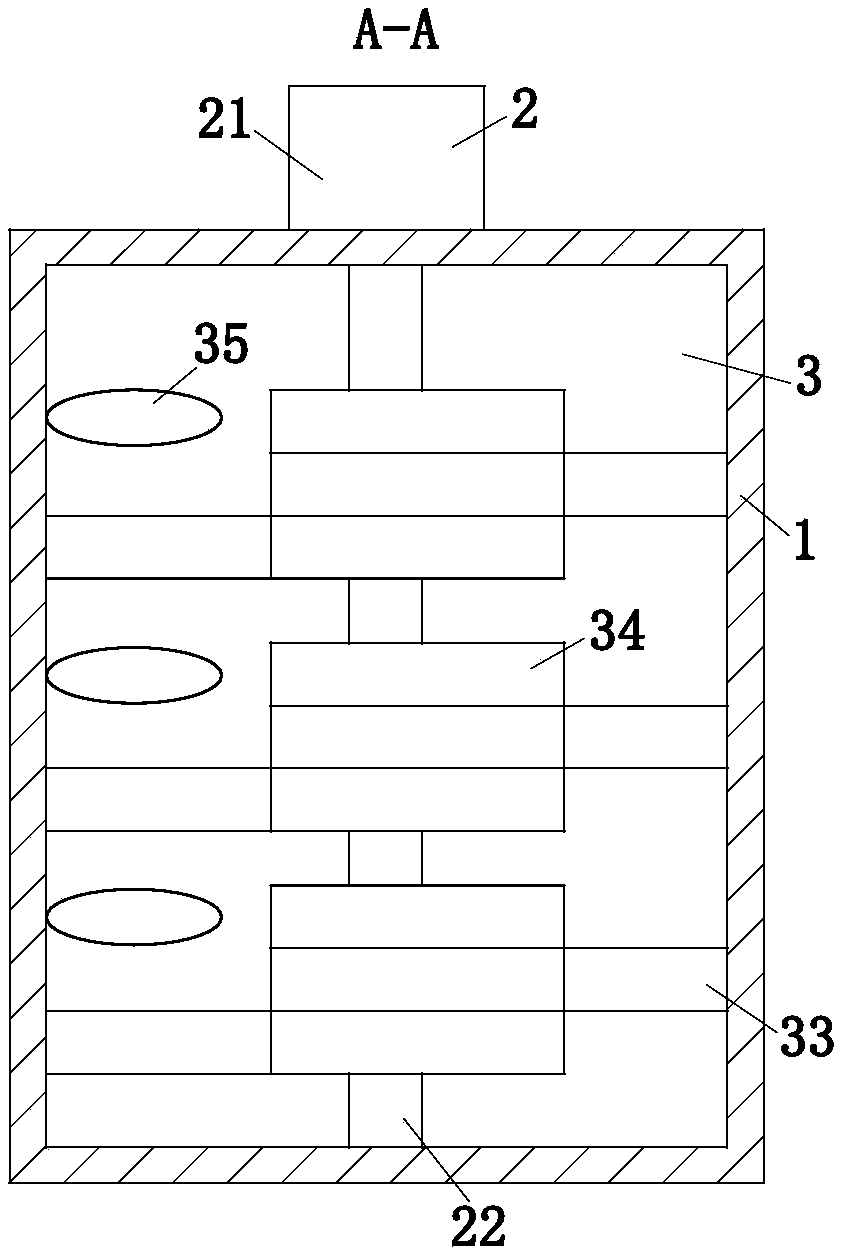

Embodiment approach

[0043] As an embodiment of the present invention, the No. 1 slider 5 is provided with a No. 1 channel 51; the piston plate in the No. 1 cylinder 6 is provided with a No. 2 channel 61; the arc plate 4 is provided with a No. 3 channel. Passage 44; said No. 1 passage 51, No. 2 passage 61 and No. 3 passage 44 communicate with each other. When the stirring unit 3 slides in the arc-shaped groove 41 through the No. 1 slider 5, the No. 1 cylinder 6 blows air outwards, The bulging gas is transported into the tank body 1 through the connected No. 1 channel 51 , No. 2 channel 61 and No. 3 channel 44 to aerate the biomass in the tank body 1 . In the present invention, through the mutual cooperation between the stirring unit 3, the No. 1 cylinder 6, the arc plate 4, the No. 1 slider 5 and the long balloon 43, the No. 1 cylinder 6 is squeezed and stretched, and the No. 1 cylinder 6 bulges outward. The bulging gas is sprayed to the tank body 1 through the connected No. 1 channel 51, No. 2 ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com