Non-silicon release agent for aluminum foil adhesive tape

A technology of aluminum foil tape and release agent, which is applied in the direction of adhesives, film/sheet adhesives, coatings, etc., can solve the problems of affecting the protection function and accelerating the aging speed of the release agent, and achieves enhanced corrosion resistance. Enhanced tensile strength and improved release properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

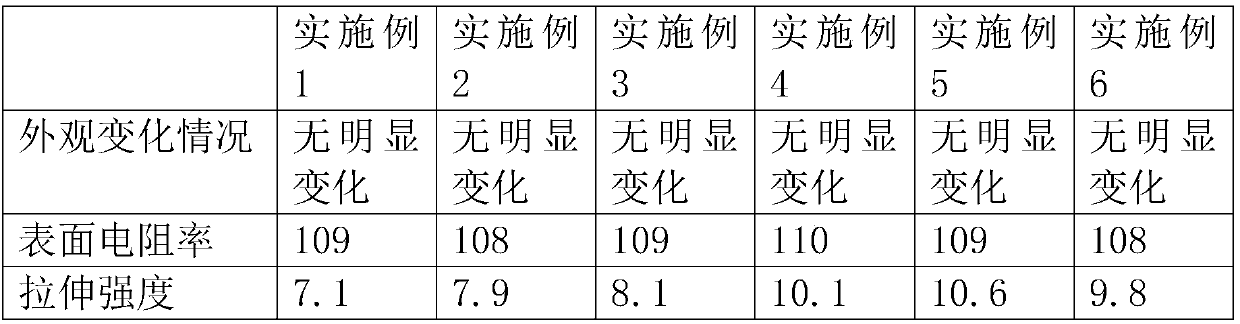

Examples

Embodiment 1

[0048] A non-silicon release agent for aluminum foil tape, comprising the following components in parts by mass:

[0049] 0.75kg stearyl acrylate; 102kg toluene; 21kg cyclohexanone; 4.5kg isocyanate; 0.45kg ethoxylated alkyl ammonium sulfate; 0.45kg carbon fiber; 0.45kg lignin coupling agent.

[0050] In this embodiment, the isocyanate is toluene diisocyanate. In other embodiments, diphenylmethane diisocyanate, dicyclohexylmethane diisocyanate, hexamethylene diisocyanate and the like can also be used as the isocyanate.

[0051] The preparation method of non-silicon release agent for aluminum foil tape is as follows:

[0052] (1) In a 200L stirred tank, under normal temperature conditions, add 4.5kg of isocyanate and stir at a speed of 40r / min;

[0053] (2) Add 0.75 kg of stearyl acrylate, 102 kg of toluene, 21 kg of cyclohexanone, 0.45 kg of ethoxylated alkyl ammonium sulfate, 0.45 kg of carbon fiber, and 0.45 kg of lignin coupling agent while stirring, and stir evenly. Form...

Embodiment 2

[0056] A non-silicon release agent for aluminum foil tape, comprising the following components in parts by mass:

[0057]0.87kg stearyl acrylate; 119kg toluene; 24.5kg cyclohexanone; 5.25kg isocyanate; 0.53kg ethoxylated alkyl ammonium sulfate; 0.53kg carbon fiber; 0.53kg lignin coupling agent.

[0058] In this example, the isocyanate is diphenylmethane diisocyanate.

[0059] The preparation method of non-silicon release agent for aluminum foil tape is as follows:

[0060] (1) In a 200L stirred tank, under normal temperature conditions, add 5.25kg of isocyanate and stir at a speed of 40r / min;

[0061] (2) While stirring, add 0.87kg of stearyl acrylate, 119kg of toluene, 24.5kg of cyclohexanone, 0.53kg of ethoxylated alkyl ammonium sulfate, 0.53kg of carbon fiber, and 0.53kg of lignin coupling agent, and stir evenly , forming a non-silicon release agent for aluminum foil tape;

[0062] (3) Apply the uniformly stirred non-silicon release agent on the back of the aluminum foil...

Embodiment 3

[0064] A non-silicon release agent for aluminum foil tape, comprising the following components in parts by mass:

[0065] Stearyl acrylate 1kg; toluene 136kg; cyclohexanone 28kg; isocyanate 6kg; ethoxylated alkyl ammonium sulfate 0.6kg; carbon fiber 0.6kg; lignin coupling agent 0.6kg.

[0066] In this embodiment, the isocyanate is dicyclohexylmethane diisocyanate.

[0067] The preparation method of non-silicon release agent for aluminum foil tape is as follows:

[0068] (1) In a 200L stirred tank, under normal temperature conditions, add 6kg of isocyanate and stir at a speed of 40r / min;

[0069] (2) While stirring, add 1 kg of stearyl acrylate, 136 kg of toluene, 28 kg of cyclohexanone, 0.6 kg of ethoxylated alkyl ammonium sulfate, 0.6 kg of carbon fiber, and 0.6 kg of lignin coupling agent, and stir evenly to form Aluminum foil tape non-silicon release agent;

[0070] (3) Apply the uniformly stirred non-silicon release agent on the back of the aluminum foil tape with a coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com