Device and method for realizing glass ceramic crystallization through microwave-electric hybrid heating

A glass-ceramic and microwave heating technology, applied in electric furnace heating, lighting and heating equipment, charge composition/state, etc., can solve the problems of difficulty in ensuring crystallization quality, high energy consumption, etc., to avoid product cracking, improve quality, eliminate effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

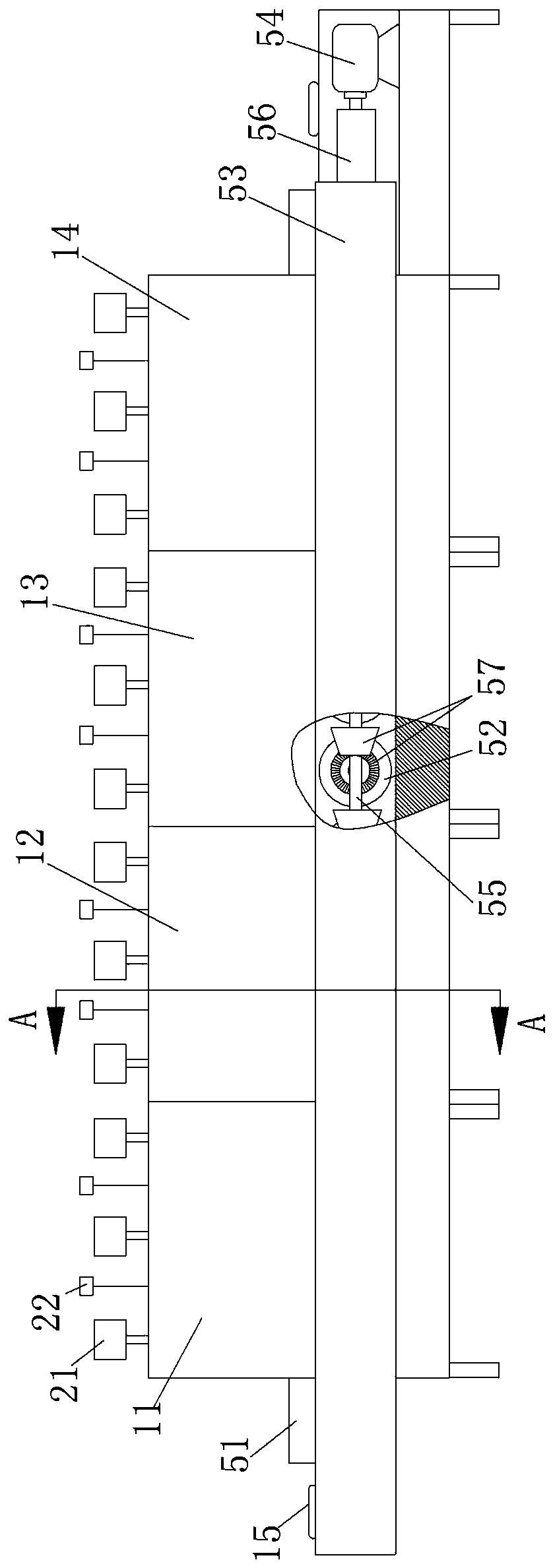

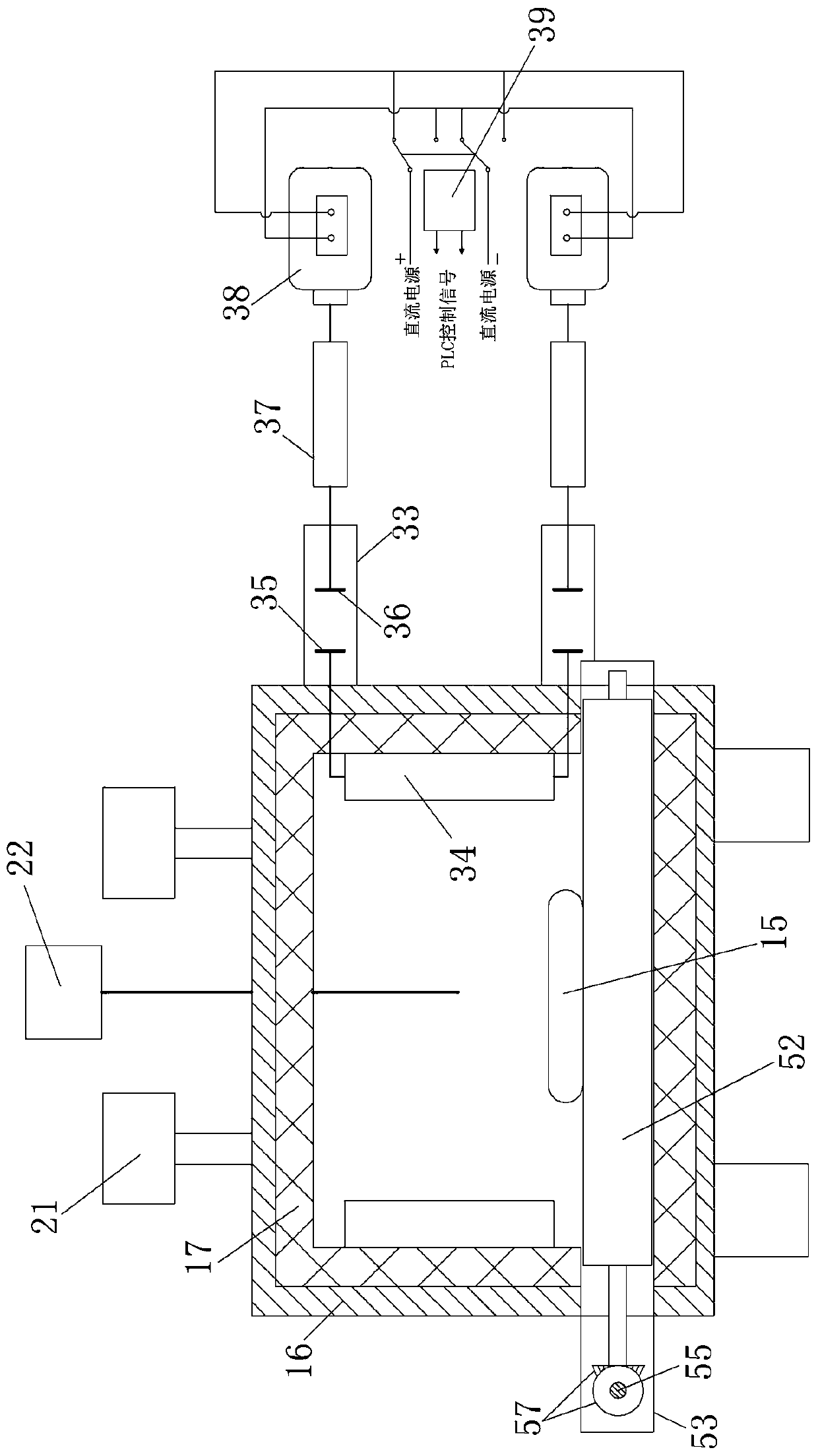

[0029] Embodiment one: see Figure 1-3 , a microwave-electric hybrid heating device for crystallizing glass ceramics, including a main furnace body, a microwave heating system, an electric heating system, and a transmission system;

[0030] The main furnace body includes a heating section (11), a crystallization section (12), a cooling section (13) and a cooling section (14) which are sealed and docked in sequence; a furnace (16) is arranged inside each section of the main furnace body, An insulating layer (17) is provided on the inner wall of the furnace (16), and a microwave heating system comprising a microwave emission system (21) and a thermocouple (22) is formed on the top of each section of the main furnace body, and the thermocouple (22) run through the main furnace body and extend into the interior of the main furnace body;

[0031] The sides of each section of the main furnace body are equipped with an electric heating system; the electric heating system includes el...

Embodiment 2

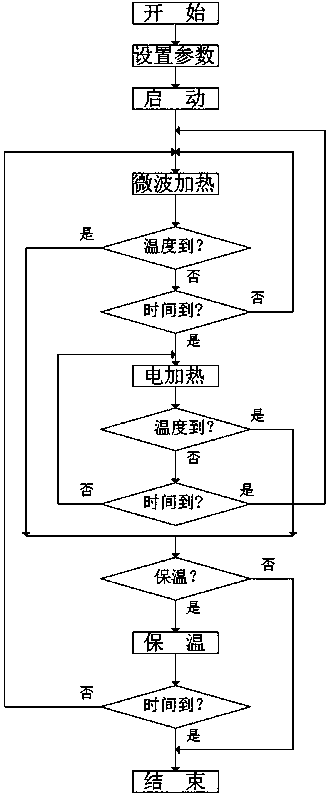

[0053] Embodiment two: see Figure 1-3 A method for crystallizing glass-ceramics by utilizing the microwave-electric hybrid heating of Embodiment 1 to realize the glass-ceramic crystallization device comprises the following steps:

[0054] ①The material to be crystallized (15) enters the heating section (11) through the roller table formed by the rotating roller (52) through the entrance microwave suppression device (51). (36) Propel and contact with the end (35) of the lead wire of the electric heating element by the forward and backward actuator (37), then power on after a delay of 3 seconds, adjust the electric heating power to 40KW, and heat up to 400°C at a rate of 3°C per minute; Then open the microwave-electric hybrid heating system, that is, cut off the electric heating power supply earlier, and after a delay of 3 seconds, the power line contact (36) withdraws from the advance and retreat actuator (37) by 50mm; The output power is 30KW, turn off the microwave heating ...

Embodiment 3

[0058] Embodiment three: see Figure 1-3 A method for crystallizing glass-ceramics by utilizing the microwave-electric hybrid heating of Embodiment 1 to realize the glass-ceramic crystallization device comprises the following steps:

[0059] ①The material to be crystallized (15) enters the heating section (11) through the roller table formed by the rotating roller (52) through the entrance microwave suppression device (51). (36) Propel and contact with the end (35) of the lead wire of the electric heating element by the advancing and retreating actuator (37), then power on after a delay of 4 seconds, adjust the electric heating power to 45KW, and raise the temperature to 420°C at a rate of 2°C per minute, Then turn on the microwave-electric hybrid heating and cut off the electric heating power supply first, and after a delay of 4 seconds, the power line contact (36) withdraws 55mm from the advance and retreat actuator (37); simultaneously start the microwave emission system (2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com