An online automatic storage moisture-proof and oxidation-proof nitrogen gas cabinet

An automatic storage and anti-oxidation technology, applied in the field of nitrogen gas cabinets, can solve problems such as low efficiency and inability to meet the needs of automated production, and achieve the effects of reducing costs, shortening transportation distances, and improving storage efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

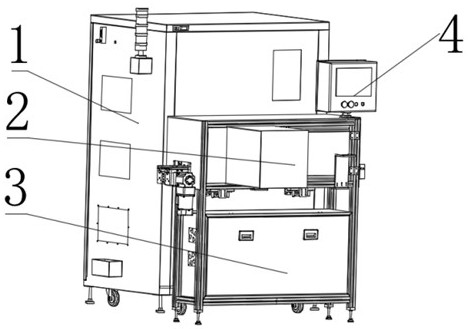

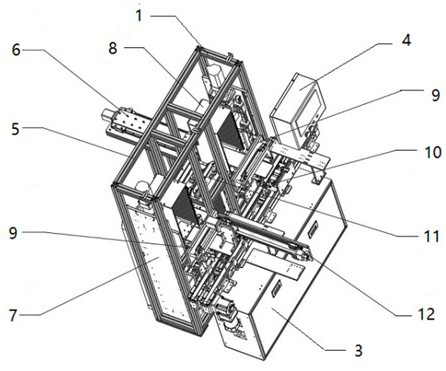

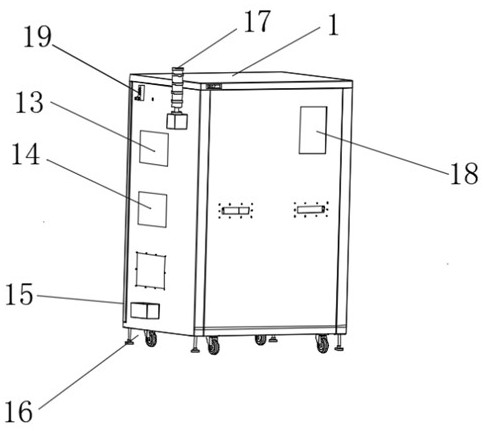

[0035] Such as Figure 1-3 As shown, in the embodiment of the present invention, an online automatic storage moisture-proof and anti-oxidation nitrogen cabinet includes a connecting line body 2 and a sheet metal welding cabinet body 1, and the connecting line body 2 is installed on the sheet metal welding cabinet body 1 Above, two material frames 8 are installed inside the sheet metal welding cabinet body 1, a first transfer mechanism 11 is installed inside the sheet metal welding cabinet body 1 between the two material frames 8, and a door sealing mechanism assembly is installed at the front end of the material frame 8. 9, a first jacking mechanism 10 is installed at the front end of the door sealing mechanism assembly 9, a feeding mechanism 12 is installed at the front end of the sheet metal welding cabinet body 1, and a pushing mechanism 6 is installed on the rear end surface of the sheet metal welding cabinet body 1. A lifting mechanism 7 is respectively installed on both ...

Embodiment 2

[0040] An online automatic storage moisture-proof and oxidation-proof nitrogen gas cabinet, such as Figure 4-10 As shown, the embodiment of the present invention is further limited on the basis of embodiment 1.

[0041] Further, preferably, the pushing mechanism 6 is provided with a base plate 62, the upper end of the base plate 62 is equipped with a first screw mandrel 63, the port of the first screw mandrel 63 is equipped with a first stepping motor 61, and the lower end of the first screw mandrel 63 is A guide rail 64 is installed, and a push plate 65 is installed on the upper end of the first screw mandrel 63 .

[0042] Further, preferably, a first support plate 76 is installed on the lifting mechanism 7, a first servo motor 71 is installed on the top of the first support plate 76, a first reducer 72 is installed at the lower end of the first servo motor 71, and the first support The first linear guide rail 73 and the second screw mandrel 74 are installed on the plate 76...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com