Rotary electric trimmer inner cutter head

A trimmer and rotary technology, applied in metal processing and other directions, can solve problems such as poor sound and sharpness, nasal cavity strain, and inability to install multiple cutter heads, achieving high sound consistency, improving shaving comfort, and shaving at the same time Good axis and sharpness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

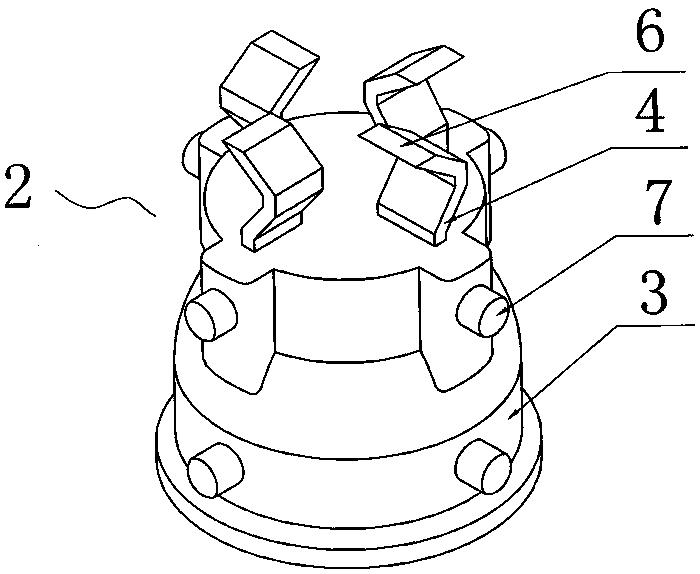

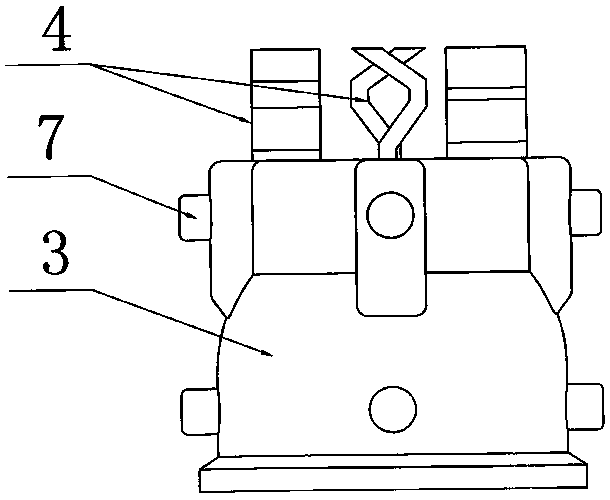

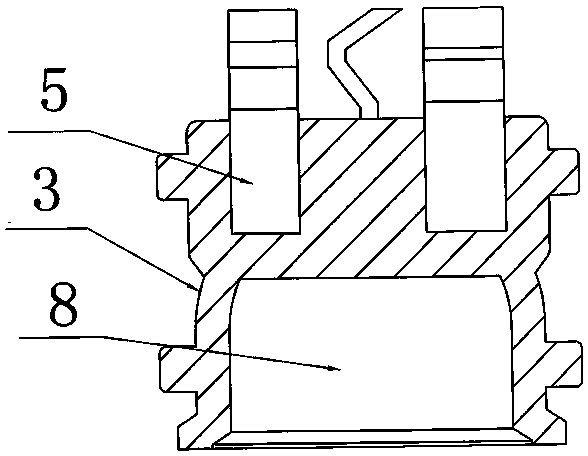

[0016] Embodiment 1: As shown in the accompanying drawings, a rotary electric trimmer inner cutter head includes an outer cutter 1 and an inner cutter 2, and the inner cutter 2 includes a plastic part 3 and four blades 4, and the blades 4 Fixedly connected with the connecting piece 3, the blade 4 includes a connecting portion 5, and the connecting portion 5 is fixedly inserted into the matching slot provided in the plastic part 3, and the upper end of the blade 4 is provided with a blade 6, the The plastic part 3 is provided with 8 protrusions 7 which are socketed with the outer knife 1. The protrusions 7 are arranged in two rows up and down, and 4 of each row are evenly distributed on the outer ring of the plastic part 3. Also be provided with the groove 8 that connects linkage shaft. The height of the outer knife 1 is 3mm shorter than the height of the inner knife 2 . The inner blade height of the rotary electric trimmer is 11mm.

Embodiment 2

[0017] Embodiment 2: Another internal cutter head of a rotary electric trimmer, including an outer cutter 1 and an inner cutter 2, the inner cutter 2 includes a plastic part 3 and two blades 4, and the height of the outer cutter 1 is higher than that of the inner cutter 2 1mm shorter. The inner blade height of the rotary electric trimmer is 10mm.

[0018] Embodiment 2: Another inner cutter head of a rotary electric trimmer, including an outer cutter 1 and an inner cutter 2, the inner cutter 2 includes a plastic part 3 and six blades 4, and the height of the outer cutter 1 is higher than that of the inner cutter 2 4mm shorter. The inner blade height of the rotary electric trimmer is 13mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com