Method for extracting and preparing 4,4'-dimethylsterol from shea nut butter

A technology of dimethyl sterol and shea butter, applied in the field of separation engineering, can solve the problems of low product yield, cumbersome process, complicated process, etc., and achieve the effect of high purity, simple process and high extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Take 30 grams of shea butter, put it into a flask for saponification, add 200 mL of potassium hydroxide ethanol solution with a concentration of 1 mol / L, reflux and saponify at 105° C. for 1 hour, and collect the oily liquid after saponification;

[0035] (2) Add 120mL of n-hexane to the oily liquid after saponification, separate layers, let go of the lower liquid, take the upper liquid organic layer, wash twice with 40°C warm water 240mL, and separate the liquid to obtain The feed liquid of base sterol;

[0036] (3) Distill the feed solution containing 4,4'-dimethylsterol at 37°C and -0.09MPa to remove n-hexane to obtain 2.3 grams of 4,4'-dimethylsterol enrichment;

[0037] (4) Add 2.3 grams of 4,4'-dimethyl sterol enrichment to 23 mL of ethanol and raise the temperature to 60°C to dissolve, then cool the solution to 25°C to crystallize, grow crystals for 8 hours, and separate to obtain 4,4' - Dimethyl sterol crystals, yield 46.9%.

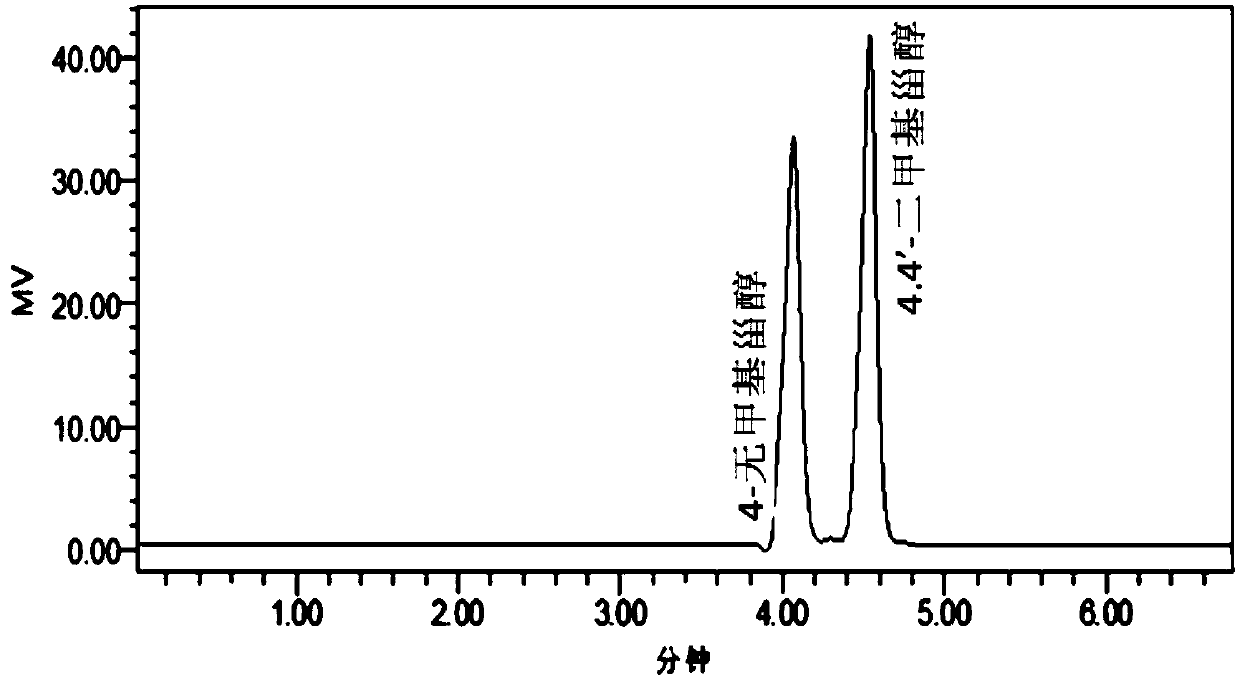

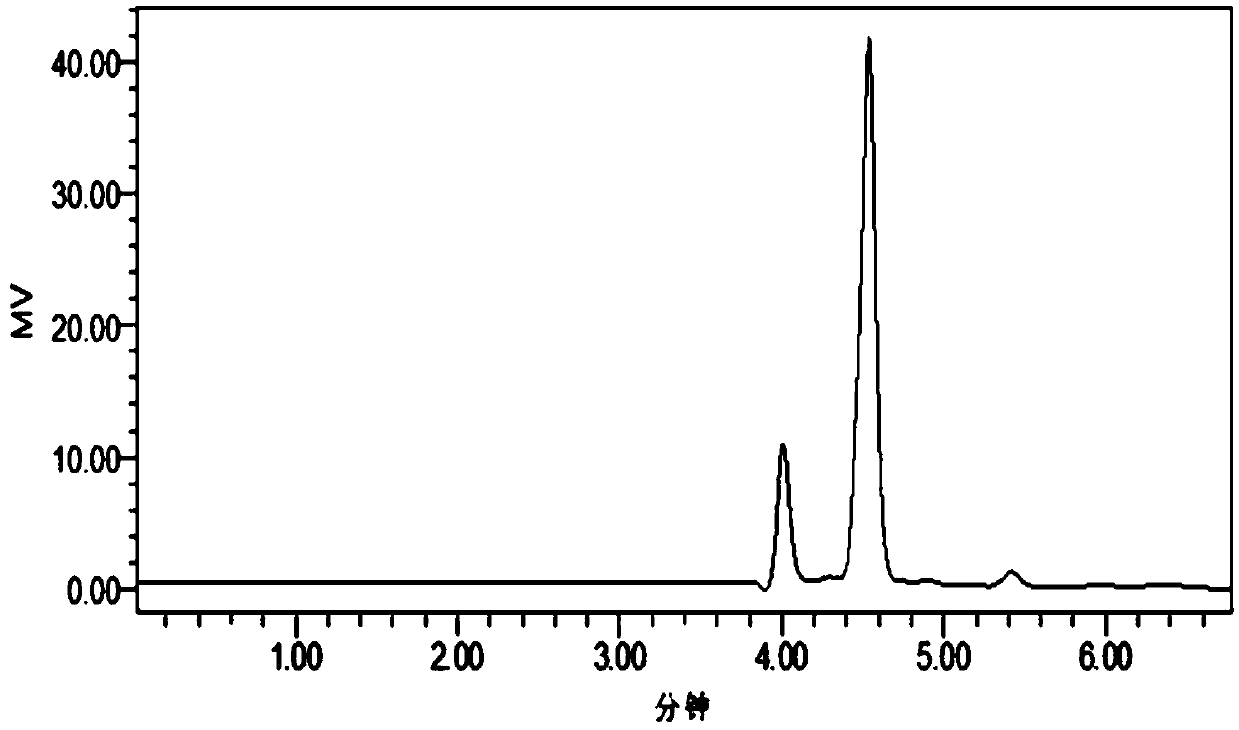

[0038] figure 1 It is the no...

Embodiment 2

[0042] (1) Take 30 grams of shea butter, put it into a flask for saponification, add 200 mL of potassium hydroxide ethanol solution with a concentration of 1 mol / L, reflux and saponify at 105° C. for 1 hour, and collect the oily liquid after saponification;

[0043] (2) Add 250mL of petroleum ether to the oily liquid after saponification, separate layers, let go of the lower liquid, take the upper liquid organic layer, wash twice with 55°C warm water 250mL, and separate the liquid to obtain The feed liquid of base sterol;

[0044] (3) Evaporate the feed liquid containing 4,4'-dimethyl sterol at 37°C and -0.09 MPa to remove petroleum ether to obtain 3.2 grams of 4,4'-dimethyl sterol enrichment;

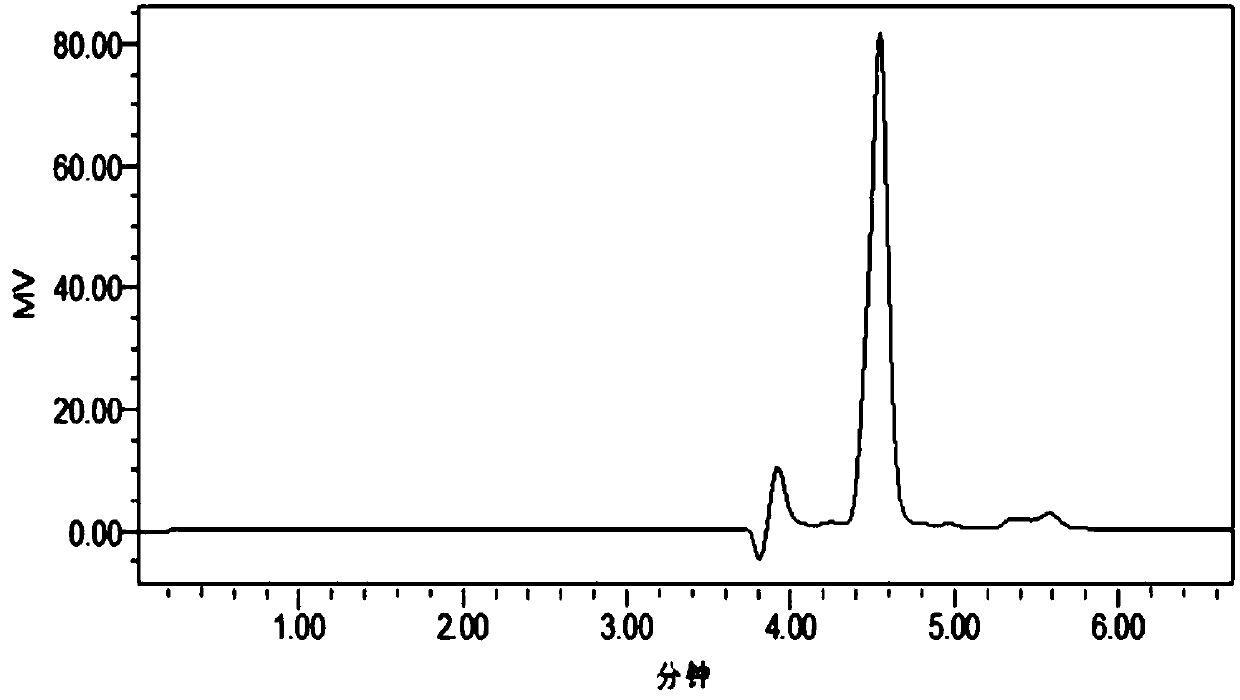

[0045] (4) Add 2.3 grams of 4,4'-dimethyl sterol enrichment into 50 mL of acetone and heat up to 65°C to dissolve, then cool the solution to 30°C to crystallize, grow crystals for 10 hours, and separate to obtain 4,4' - Dimethyl sterol crystals, yield 67.2%. image 3 For the prepared...

Embodiment 3

[0047] (1) Take 30 grams of shea butter, put it into a flask for saponification, add 200 mL of potassium hydroxide ethanol solution with a concentration of 1 mol / L, reflux and saponify at 105° C. for 1 hour, and collect the oily liquid after saponification;

[0048] (2) Add 250mL of n-hexane to the oily liquid after saponification, separate layers, let go of the lower liquid, take the upper liquid organic layer, wash twice with 300mL of warm water at 85°C, and separate liquids to obtain The feed liquid of base sterol;

[0049] (3) Evaporate the feed solution containing 4,4'-dimethyl sterol at 37°C and -0.09 MPa to remove n-hexane to obtain 4.2 grams of 4,4'-dimethyl sterol enrichment;

[0050] (4) Add 4.2 grams of 4,4'-dimethyl sterol enrichment to 100 mL of a mixed solution of ethanol and isopropanol (1:2, v / v) and heat up to 75°C to dissolve, and then the solution Cool to 25°C for crystallization, grow the crystals for 12 hours, and obtain 4,4'-dimethyl sterol crystals with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com