Weeding corrosion inhibition granule and preparation method thereof

A technology of slow-release granules and granules, applied in herbicides and algaecides, botanical equipment and methods, biocides, etc. The effect of avoiding repeated application, short process route and preventing product waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

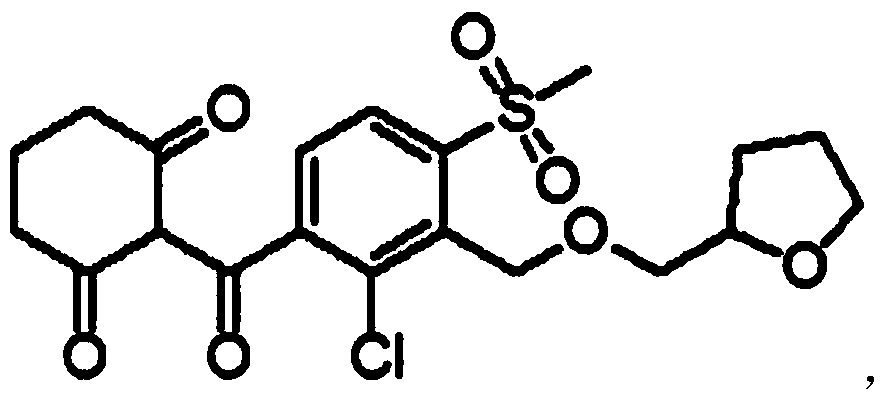

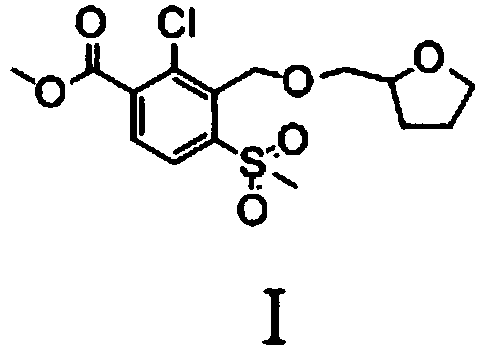

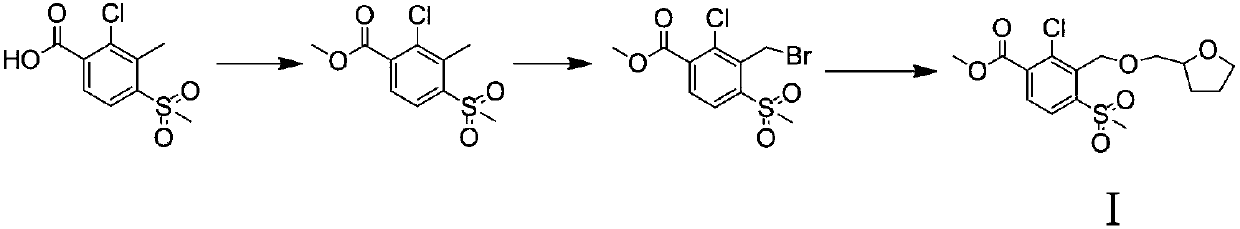

[0050] The process of preparing furansulcotrione is as follows:

[0051] Take 20ml of methanol into a three-neck bottle, then weigh 3g of 2-chloro-3-methyl-4-methanesulfonylbenzoic acid and add it, then put it into the rotor, add 10ml of methanol, install a reflux device and a thermometer, and The mouth is coated with vacuum ester, so that the whole reaction is carried out in a sealed environment. Move the device to a magnetic stirrer and start stirring, then slowly add 1.35 g of thionyl chloride dropwise in batches. After the addition, heat up and control the temperature at 60°C. After stirring for 3 hours, the reaction is complete, and the solution turns into an oily clear liquid. Stop stirring and stop heating. Take a 350ml beaker and add tap water, the amount added is half of the capacity of the beaker, after the reaction solution is naturally cooled, pour the reaction solution into the beaker, the reaction solution quickly crystallizes into a white solid, then suck the s...

Embodiment 2-5

[0056] To prepare herbicidal sustained-release granules:

[0057] (1) Raw materials are prepared according to the proportioning in Table 1; furansulcotrione is prepared in the manner of Example 1;

[0058] (2) Add 4000 g of bentonite powder with a particle size of 4000 g of water to prepare a suspension reaction system, mix furansultrione, cyprosulfuron-methyl and penoxsulam evenly and add to the reaction system, stir evenly, and then Add fatty alcohol polyoxyethylene ether sodium sulfate to it, and react the reaction system at 0.5-0.8 atmospheric pressure for 40 minutes to obtain a slurry; fatty alcohol polyoxyethylene ether sodium sulfate is a surfactant foaming agent, non-toxic, Easy to degrade, it can be used as both surfactant and foaming agent;

[0059] (3) Extrude the above slurry into a cake with a cake press machine, dry it in vacuum, and then pulverize and granulate it, with a particle size of 0.5-2 mm.

[0060] Table 1 embodiment 2-5 raw material ratio

[0061] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com