A kind of glycosylated pesticide nano-microcapsule and preparation method thereof

A nano-microcapsule and glycosylation technology, applied in botany equipment and methods, chemicals for biological control, fungicides, etc., can solve the problem of difficult particle size control, unsuitable for industrial production, low loading rate, etc. problems, to achieve the effect of increasing the degradable characteristics, improving the utilization rate of pesticides, and increasing the adhesion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

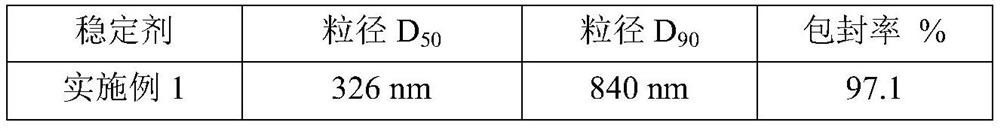

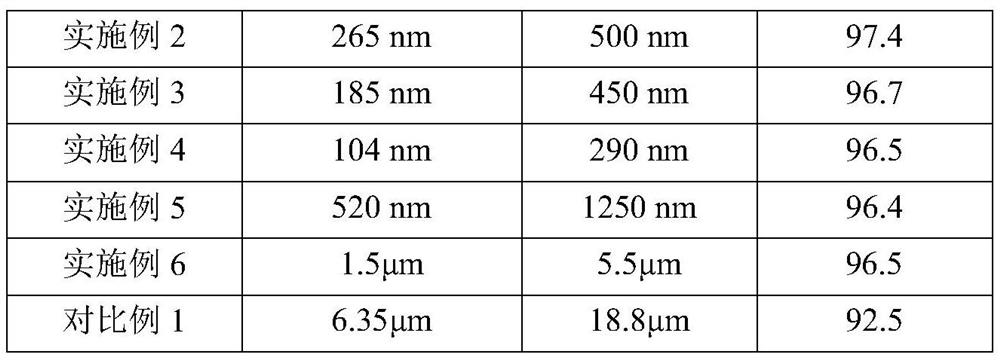

Embodiment 1

[0041] Weigh 3.00g of dried starch in a single-necked flask; weigh 1.76g of p-toluene isocyanate, mix p-toluene isocyanate with 20.00g of anhydrous ethyl acetate and add it to the single-necked flask containing starch, Install the spherical condenser, place in a water bath at 80°C, start magnetic stirring, and stop heating after 8 hours of reaction. Suction filtration, repeated washing with ethanol to obtain toluene isocyanate modified starch (modified starch A), dried for later use.

[0042] Weigh 9.28g of 97% pyraclostrobin technical substance, dissolve it with 9g of cyclohexanone and 1g of xylene, and then add 1.00g of diphenylmethane diisocyanate to form the oil phase.

[0043] Weigh 9g styrylphenol polyoxyethylene polyoxypropylene ether (emulsifier), 10g calcium lignosulfonate (dispersant) and 0.85g modified starch A (stabilizer), dissolve in 60g water, which is the water phase .

[0044] The oil phase and the water phase were mixed and ultrasonically emulsified for 11 ...

Embodiment 2

[0046]Weigh 3.00g of dried starch in a single-necked flask; weigh 2.15g of 4-ethylphenylisocyanate, mix 4-ethylphenylisocyanate with 20.00g of anhydrous ethyl acetate and add it to In the single-necked flask filled with starch, install a spherical condenser, place it in a water bath at 80°C, start magnetic stirring, and stop heating after reacting for 8 hours. Suction filtration and repeated washing with ethanol to obtain 4-ethylphenylisocyanate modified starch (modified starch B), which was dried for later use.

[0047] Weigh 9.28g of 97% pyraclostrobin technical substance, dissolve it with 9g of cyclohexanone and 1g of xylene, and then add 1.00g of diphenylmethane diisocyanate to form the oil phase.

[0048] Weigh 9g styrylphenol polyoxyethylene polyoxypropylene ether (emulsifier), 10g calcium lignosulfonate (dispersant) and 0.85g modified starch B (stabilizer), dissolve in 60g water, which is the water phase .

[0049] The oil phase and the water phase were mixed and ultr...

Embodiment 3

[0051] Weigh 3.00g of dried starch in a single-necked flask; weigh 2.35 g of 4-isopropylphenylisocyanate, mix 4-isopropylphenylisocyanate with 20.00g of anhydrous ethyl acetate and add it to the container In the single-necked flask with starch, install a spherical condenser, place it in a water bath at 80°C, start magnetic stirring, and stop heating after 8 hours of reaction. Suction filtration, repeated washing with ethanol to obtain 4-isopropylphenylisocyanate modified starch (modified starch C), dried for later use.

[0052] Weigh 9.28g of 97% pyraclostrobin technical substance, dissolve it with 9g of cyclohexanone and 1g of xylene, and then add 1.00g of diphenylmethane diisocyanate to form the oil phase.

[0053] Weigh 9g styrylphenol polyoxyethylene polyoxypropylene ether (emulsifier), 10g calcium lignosulfonate (dispersant) and 0.85g modified starch C (stabilizer), dissolve in 60g water, which is the water phase .

[0054] The oil phase and the water phase were mixed a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com