LED light emitting device

A light-emitting device, LED light source technology, applied in the direction of lighting devices, fixed lighting devices, lighting device light guides, etc., can solve the problems of difficult design of light guide plate outlets, large number of LEDs, etc., to eliminate Hotspot defects and reduce cost, and the effect of reducing design difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

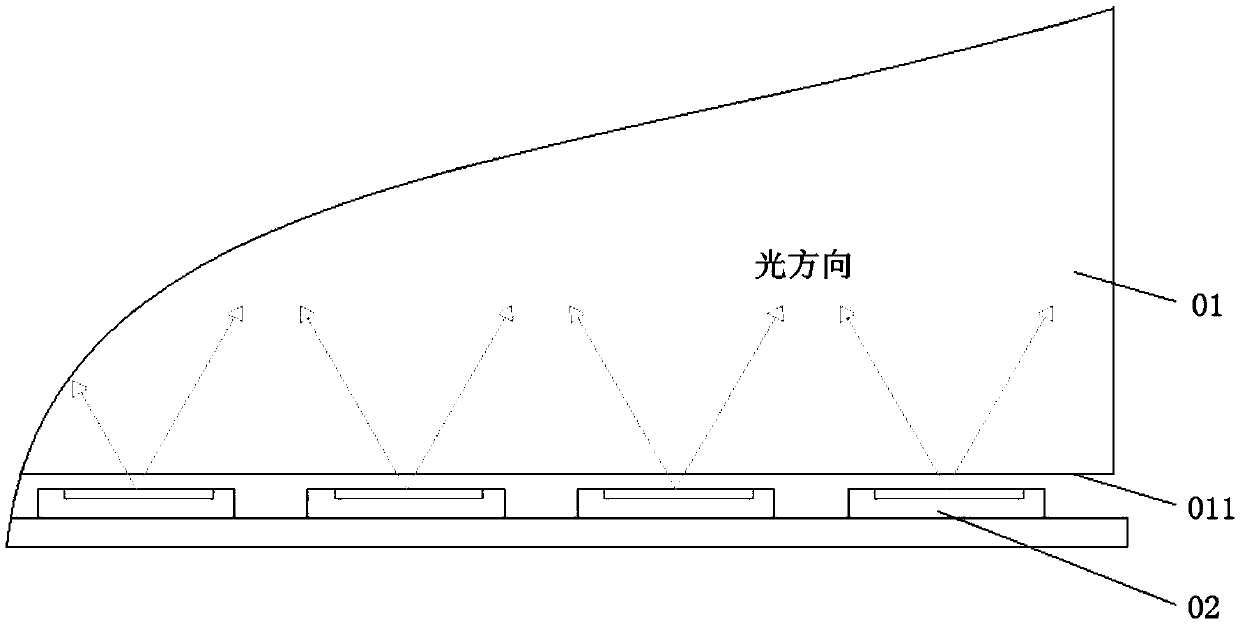

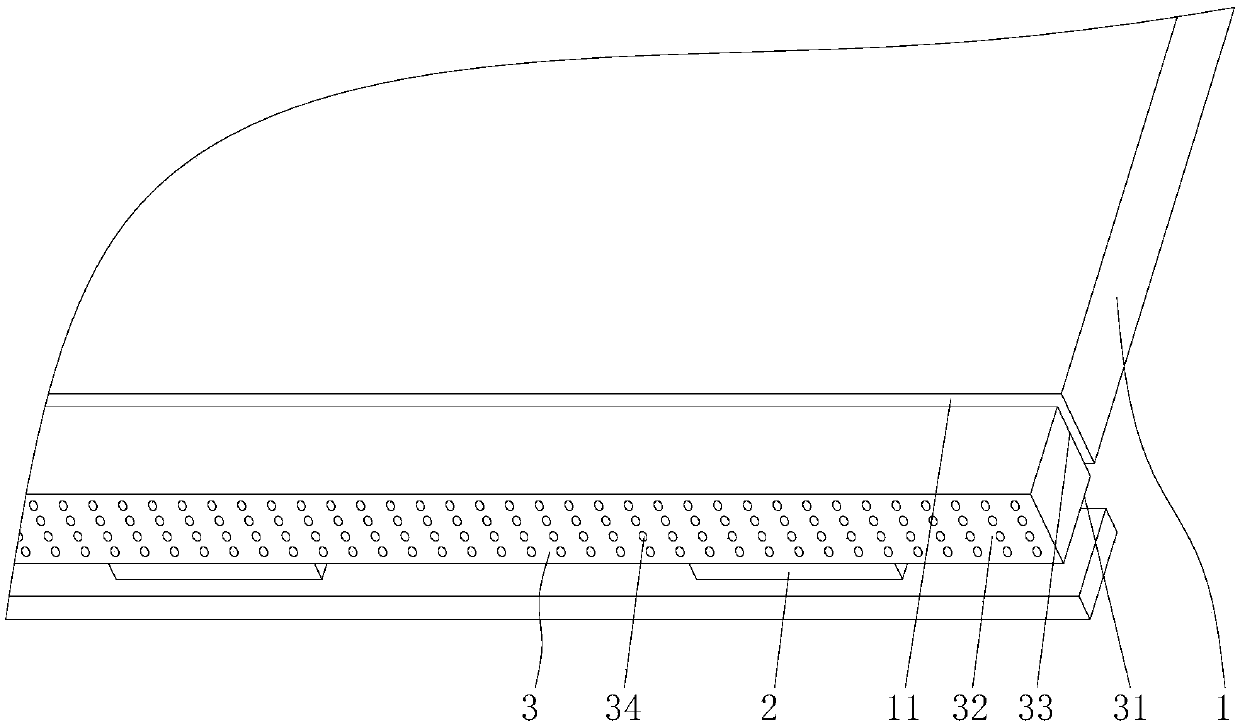

[0013] like figure 2 As shown, the LED light-emitting device of the present invention includes a backlight module, the backlight module includes an LED light source 2 and a light guide plate 1, and it also includes a light guide column 3, and the light guide column 3 includes an incident beam for receiving light beams. Surface 31, a bottom surface 32 connected to the incident surface 31 and an exit surface 33 opposite to the bottom surface 32, the bottom surface 32 is provided with a dot structure 34 for converting the incident light beam into parallel light exit, and the light guide column 3 is set On the light incident side of the light guide plate 1, and the exit surface 33 faces the light guide plate 1, the LED light source 2 is set corresponding to the incident surface 31 of the light guide column 3, and the light beam emitted by the LED light source 2 enters the light guide column 3 from the incident surface 31, passes through the dots After the structure 34 converts th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com