Integral inertial particle separator and aero-engine based on wall bounce characteristics

An integral, separator technology, applied in the field of aero-engines, can solve the problem of low separation efficiency of particle separators, and achieve the effects of reducing particles, improving separation efficiency and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

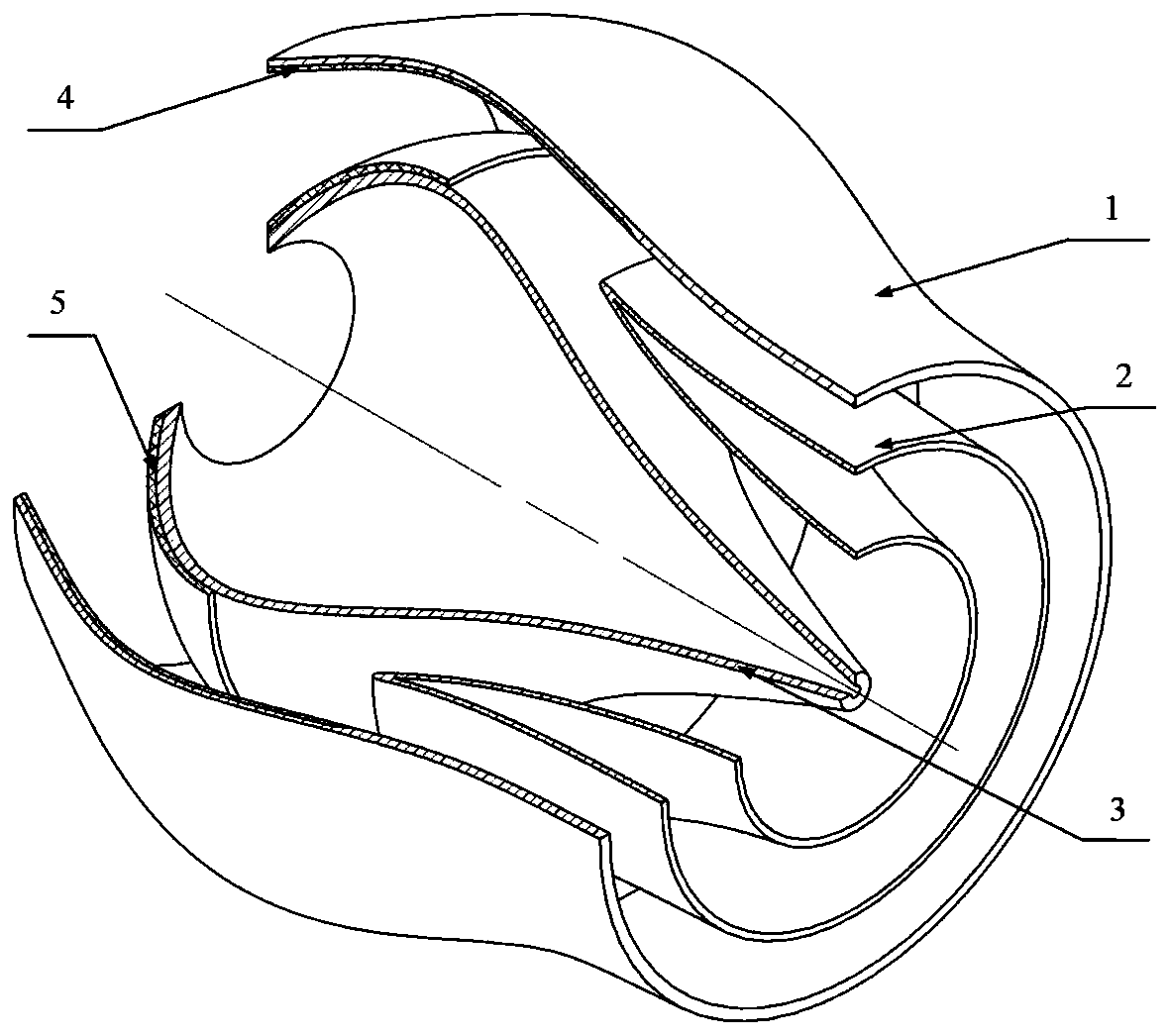

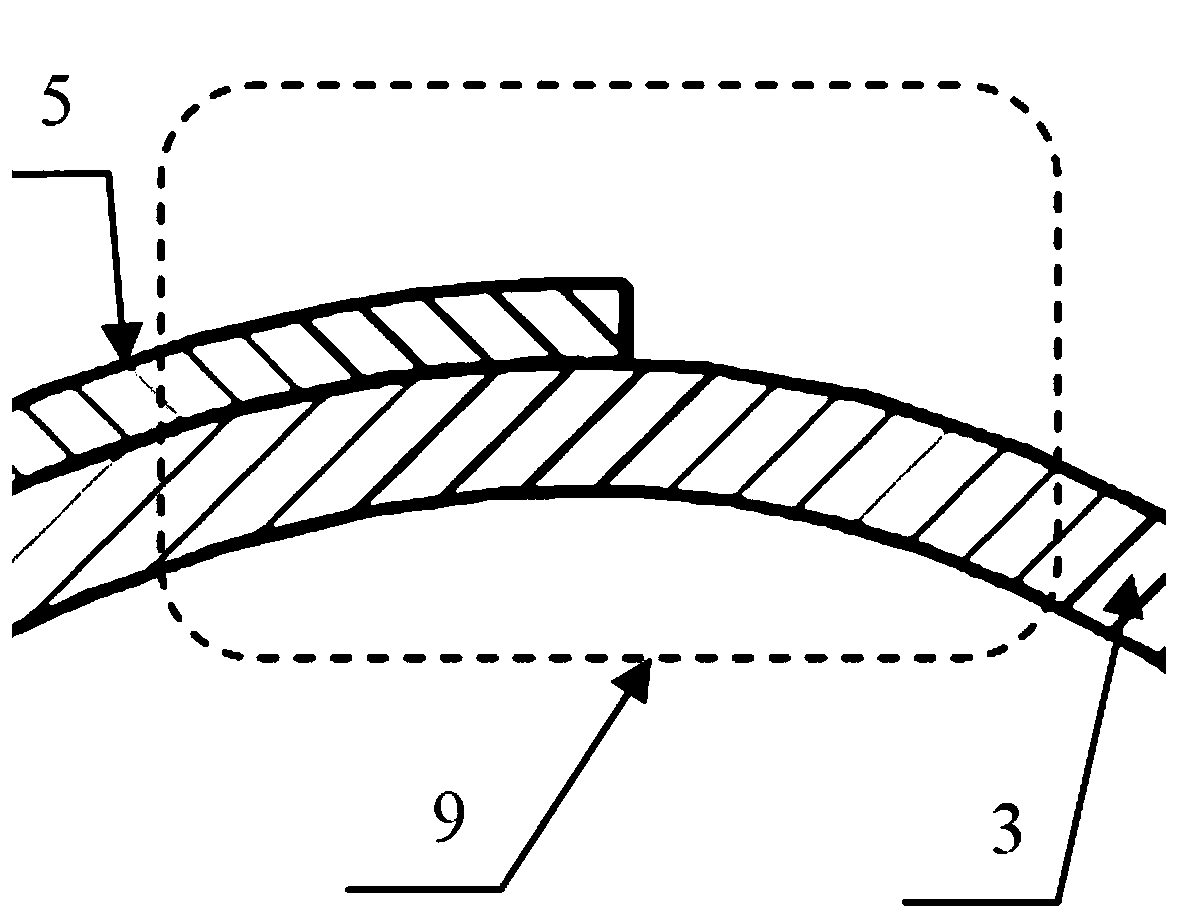

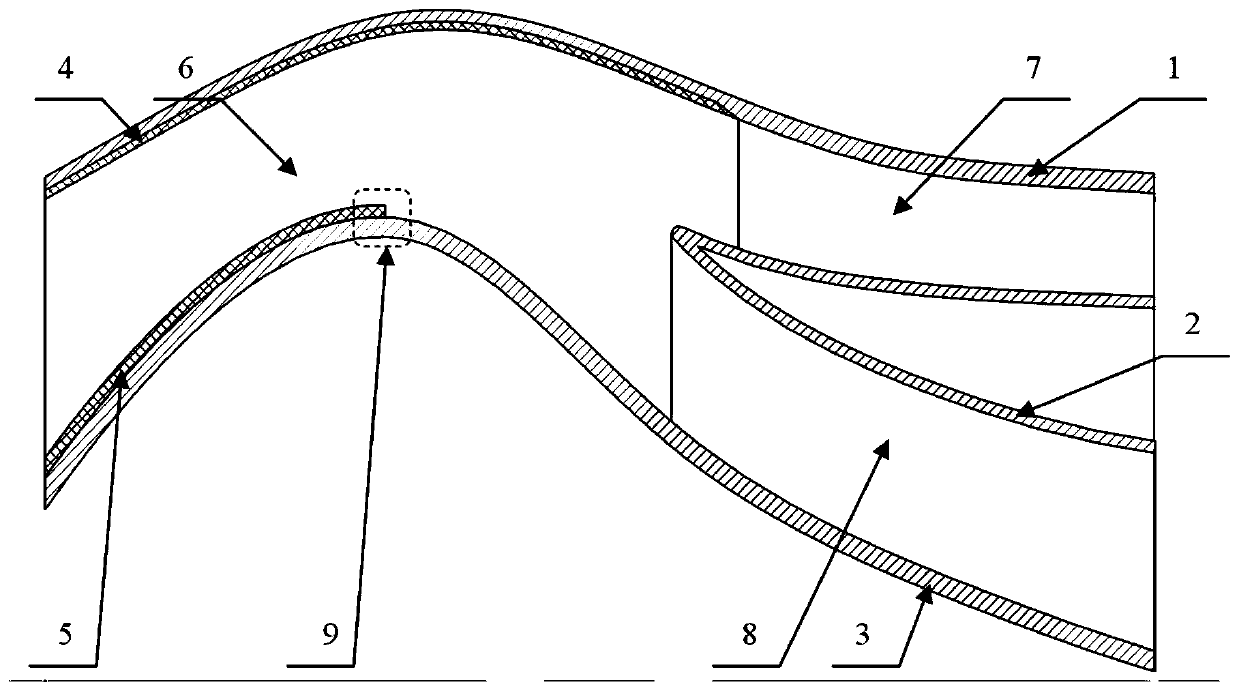

[0033] refer to figure 1 and image 3 At present, there are mainly two types of integral particle separators used in engines. One is with pre-rotating blades and the other is without pre-rotating blades. The working principle of the integral inertial particle separator is as follows:

[0034] Particle separator with pre-rotating blades, whose blades make the air entering the flow channel of the particle separator and the foreign matter contained in it obtain circumferential velocity. Under the action of inertia, foreign objects with large mass are thrown to the outer wall of the flow path and enter the cleaning flow path to be discharged out of the machine.

[0035] Compared with the parti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com