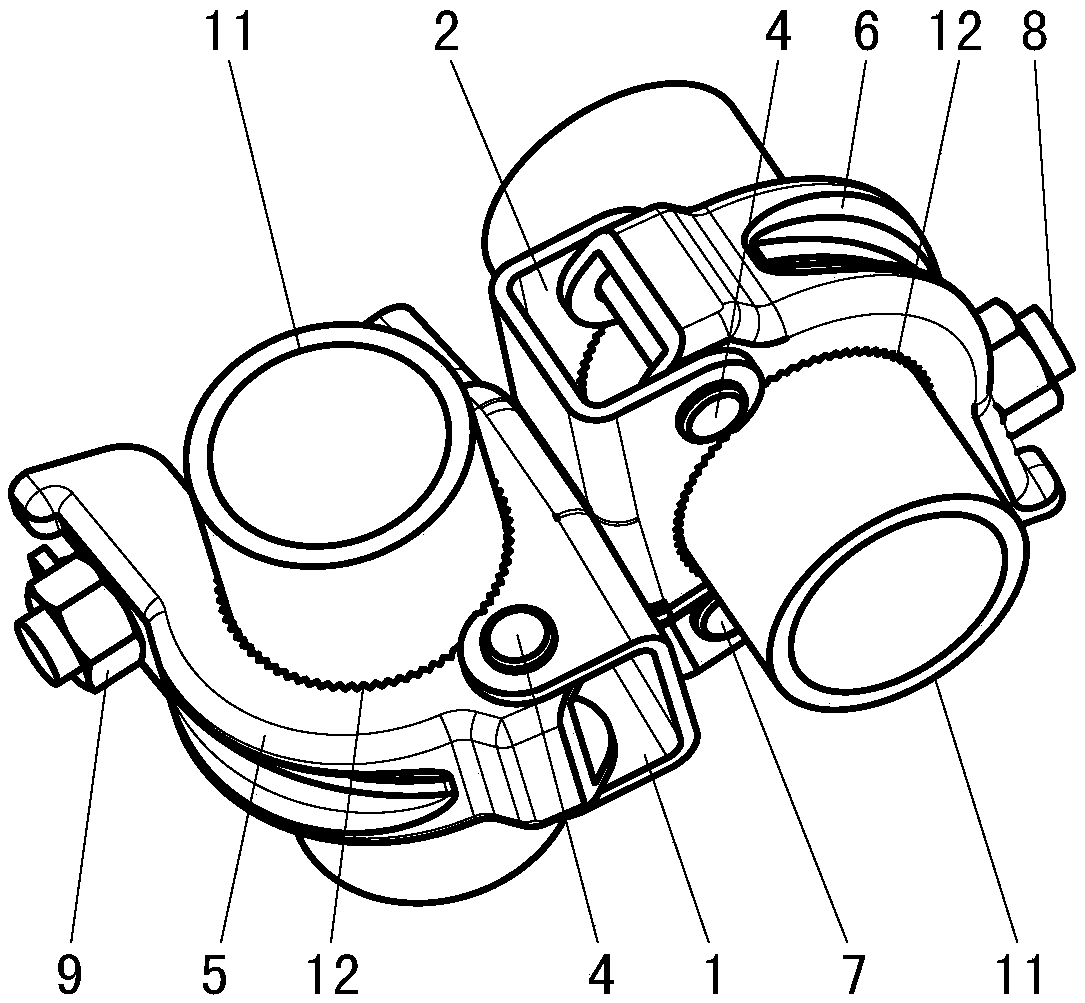

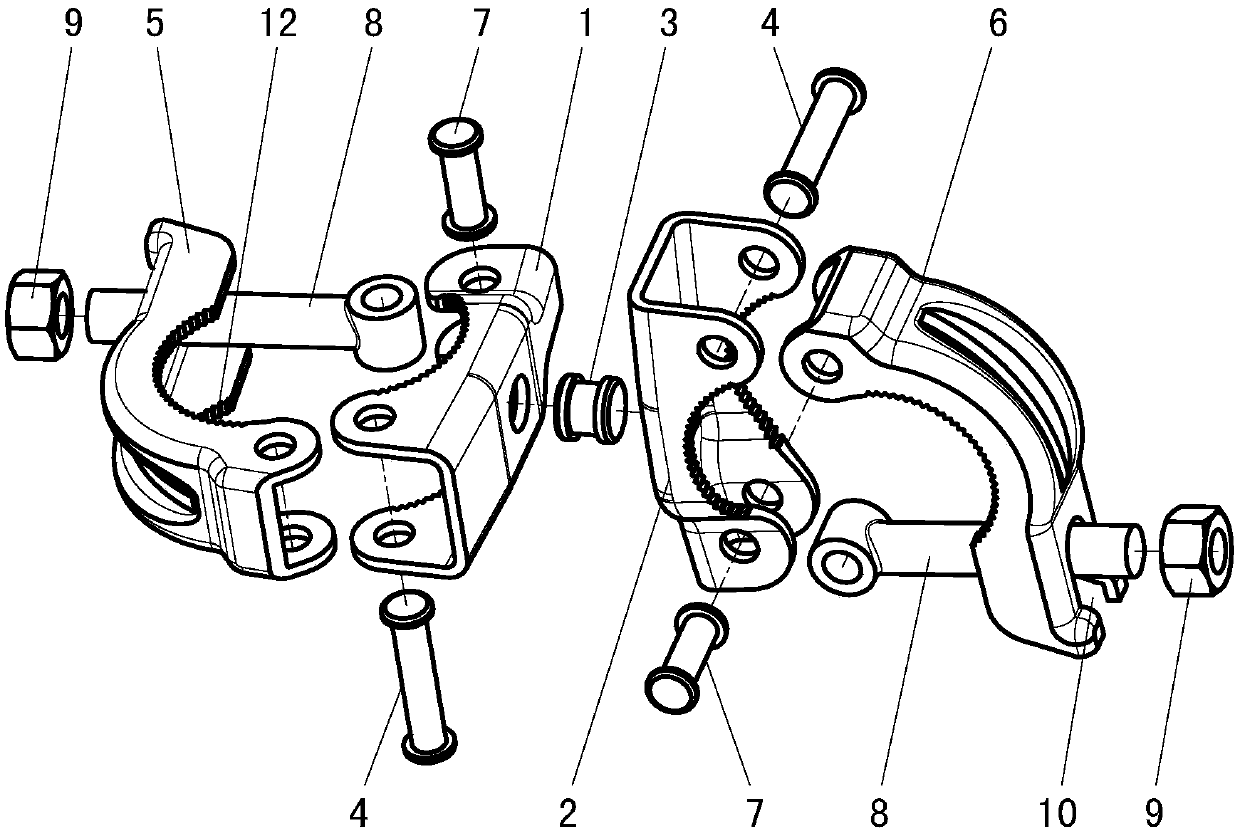

Light rotating anti-slip scaffold steel pipe buckle assembly

A scaffolding and anti-skid technology, which is applied in the connection of scaffolding, building structure support, building structure support, etc., can solve the problems of construction safety hazards, not tightly bonded with steel pipes, etc., to eliminate safety hazards, eliminate fastening illusions, strengthen Effect of detent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] During the specific implementation of this example, the left buckle, the right buckle, the left hasp and the right hasp all adopt the galvanized steel plate stamping and forming with a thickness of 3mm. The whole steel pipe buckle assembly is light, beautiful and achieves anti-corrosion effect. The steel pipe buckle assembly in this example adopts the concept of rotatable fasteners, which is suitable for cross connection fastening of two steel pipes at vertical and special angles. Considering the phenomenon that the steel pipe and the steel pipe buckle assembly are not tightly fitted, the toothed surface is used to increase the pressure, thereby greatly reducing the rotation of the steel pipe. The main parts of the steel pipe buckle assembly are processed with high strength and good corrosion resistance materials. Under the requirements of sufficient strength, durability and certain elasticity, the fastener is lighter and more beautiful than the traditional fastener, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com