Elevator control device

A technology for elevator control devices and accumulators, which is applied in the direction of AC motor control, control systems, electrical components, etc., to achieve the effects of reducing costs, reducing requirements for model selection, and reducing instantaneous current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

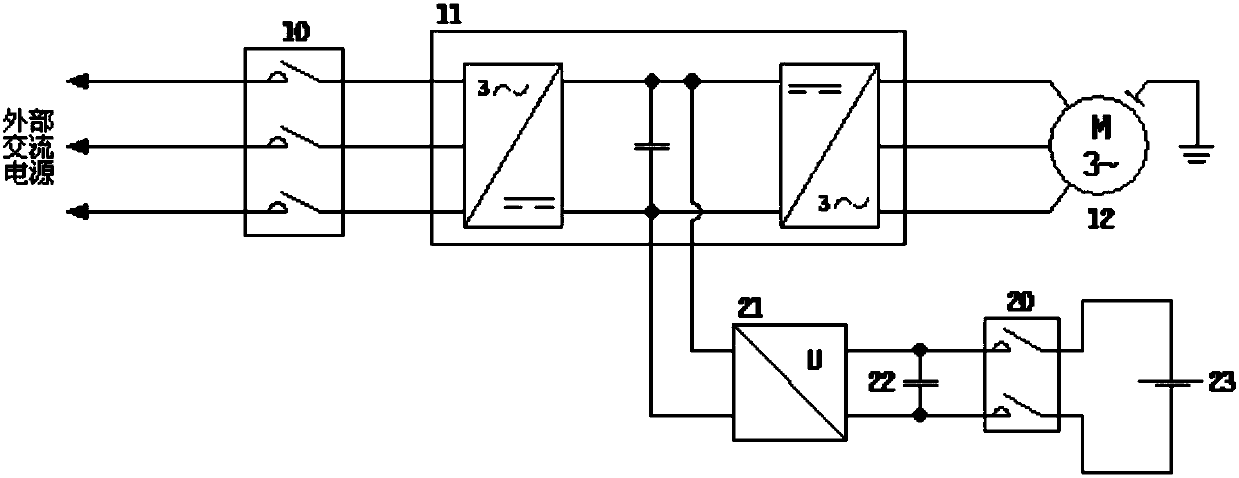

[0053] Such as figure 1 As shown, the elevator control device includes a second contactor 20, a frequency converter 11, a motor 12, a DC converter 21, a buffer capacitor 22, and an accumulator 23.

[0054] The frequency converter 11 includes a rectifier 111 and an inverter 112 for supplying power to the motor 12 and driving the motor to run;

[0055] The input terminal of the rectifier 111 is connected to an external AC power source, and a DC voltage is output to the input terminal of the inverter 112;

[0056] The inverter 112 inverts the DC voltage at its input end into an AC voltage to supply power to the motor 12;

[0057] The high-voltage terminal of the DC converter 21 is connected to the input terminal of the inverter 112;

[0058] The second contactor 20 is connected between the low-voltage end of the DC converter 21 and the accumulator 23;

[0059] The buffer capacitor 22 is disposed between the DC converter 21 and the second contactor 20, and both ends of the buffer capacitor...

Embodiment 2

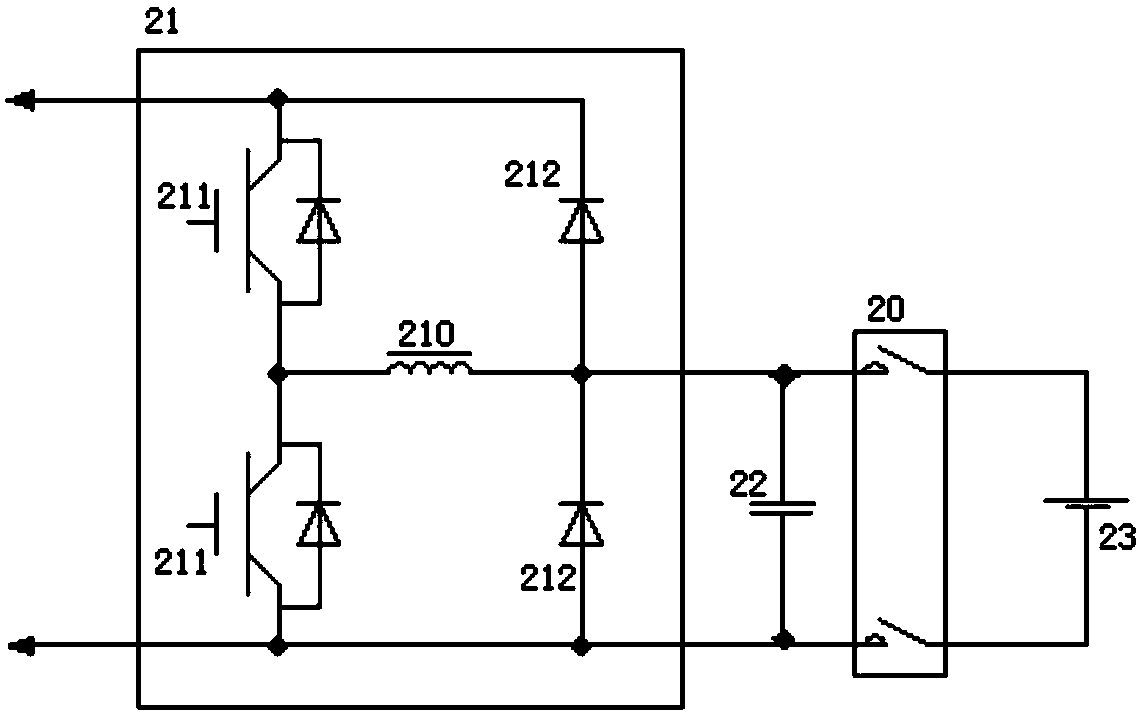

[0065] The elevator control device based on the first embodiment, such as figure 2 As shown, the DC converter 21 includes two power switch tubes 211, two diodes 212, and a built-in inductor 210;

[0066] The power switch tube 211 includes a control terminal, a first terminal, and a second terminal. The conduction or cut-off between the first terminal and the second terminal is controlled by a voltage signal applied at the control terminal;

[0067] The first terminal of the first power switch tube 211 is connected to the positive input terminal of the inverter 112;

[0068] The second end of the first power switch tube 211 is connected to the first end of the second power switch tube 211;

[0069] The second terminal of the second power switch tube 211 is connected to the negative input terminal of the inverter 112;

[0070] The negative terminal of the first diode 212 is connected to the positive input terminal of the inverter 112;

[0071] The negative terminal of the second diode 212 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com