Integrated type power assembly and electric vehicle

A powertrain and integrated technology, applied in the direction of power units, electric power units, vehicle components, etc., can solve problems such as loss of power transmission efficiency and vibration, and achieve the effects of reducing processing costs, improving transmission efficiency, and reducing vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

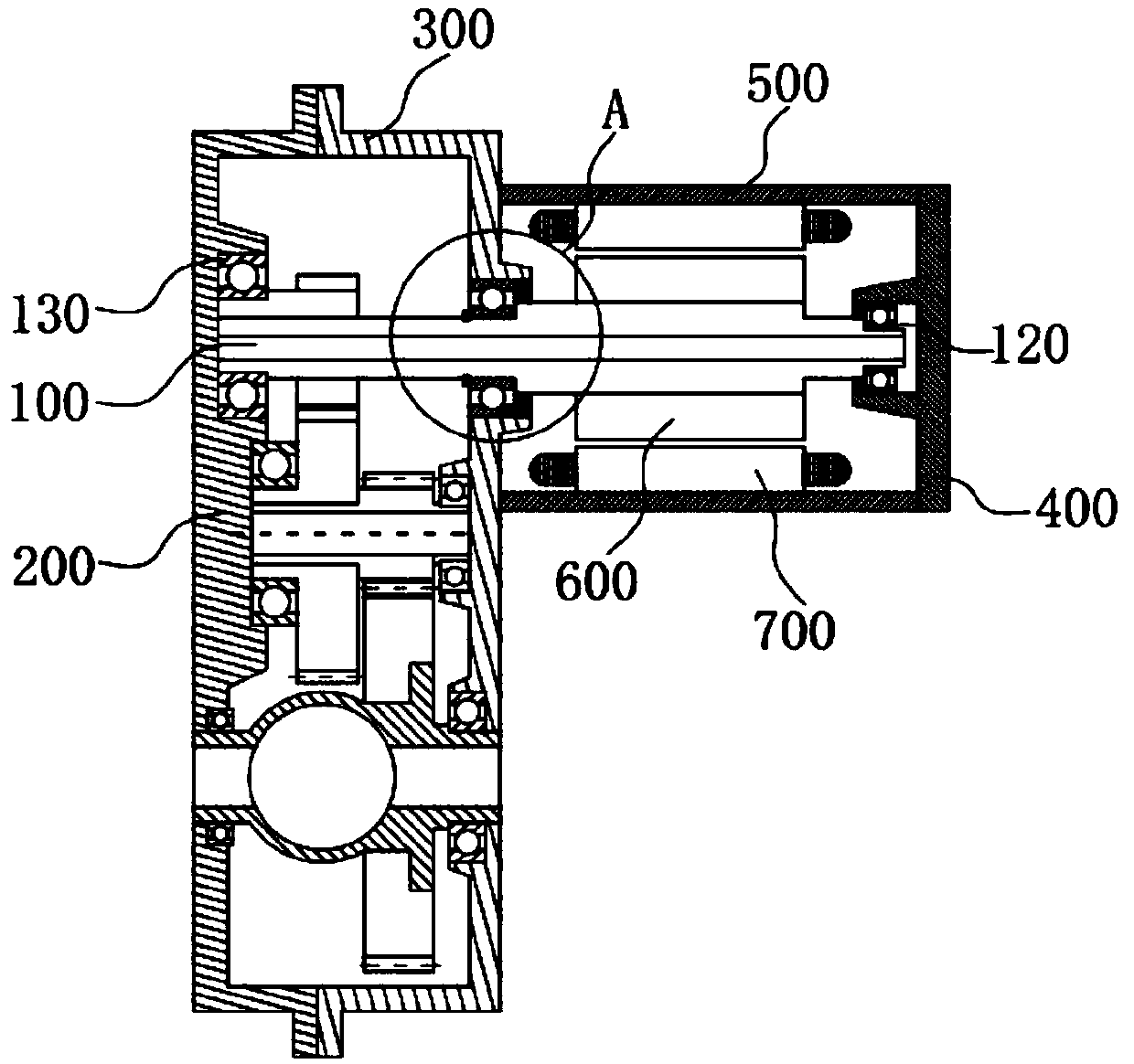

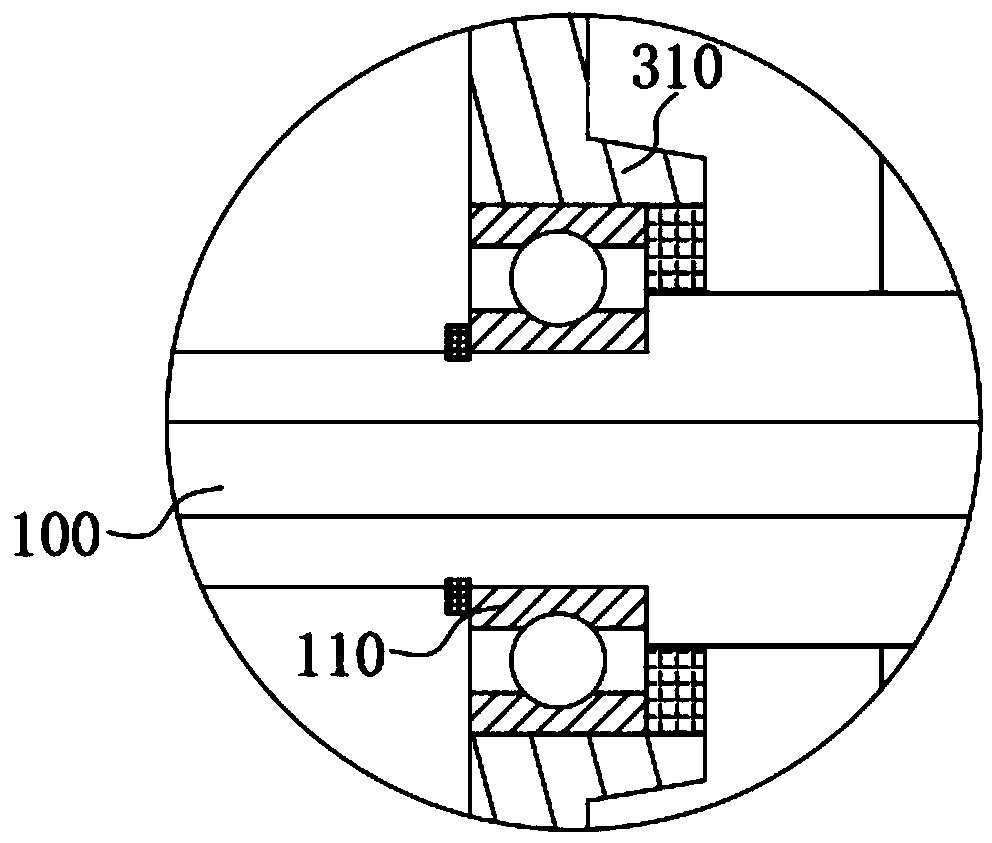

[0042] like figure 1 As shown, the first embodiment provides an integrated power assembly, including: a motor and a reducer, the motor and the reducer are connected in transmission; the rotor shaft of the motor and the input shaft of the reducer are integrally formed to form an integrated shaft 100 .

[0043] In this integrated powertrain, the rotor shaft of the motor and the input shaft of the reducer are integrally formed to form an integrated rotating shaft 100. Compared with the powertrain in the prior art, the rotor shaft and the input shaft in this embodiment Made into one, the two do not need to be connected by other parts, eliminating the spline or flange connection structure used in the prior art to connect the two, and the input shaft of the reducer is directly driven by the rotation of the rotor 600 Rotation, so as to realize the direct transmission of power.

[0044] Since the rotating shaft 100 in this embodiment is integrally formed, it can avoid the efficiency ...

Embodiment 2

[0069] Embodiment 2 provides an electric vehicle, including: the integrated powertrain in Embodiment 1.

[0070] The electric vehicle includes an integrated power assembly, wherein the specific structure, connection relationship, and beneficial effects of the integrated power assembly have been described in detail in the above text, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com