A knurled cutter head mounting assembly, straight cutter, and rotary cutter

A technology for installing components and knurling knives, which is applied in the field of knurling knives, can solve the problems of affecting the knurling effect of the knurling wheel, the swing of the knurling wheel, and the increase in the gap between the knurling wheel and the installation shaft, so as to improve convenience and avoid Oscillation, the effect of improving coaxiality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

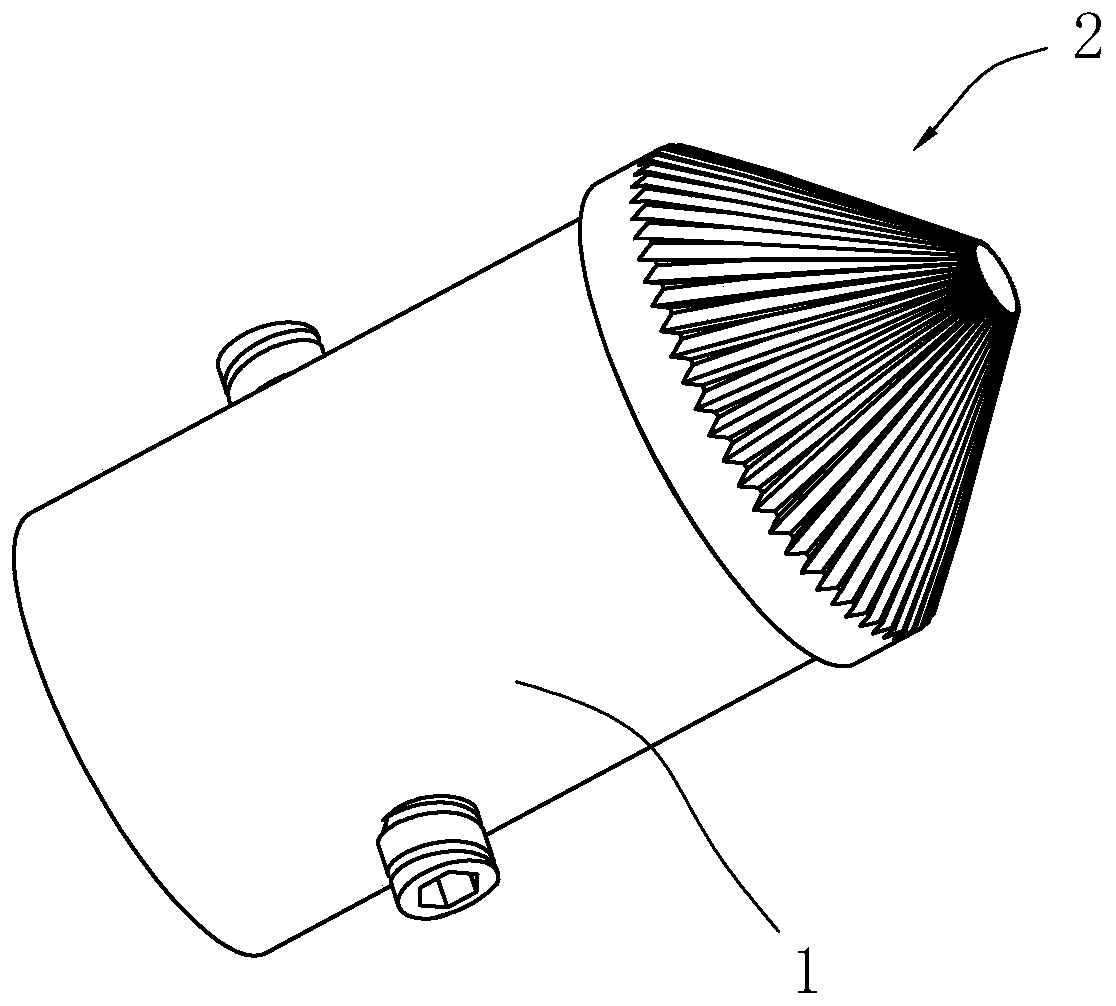

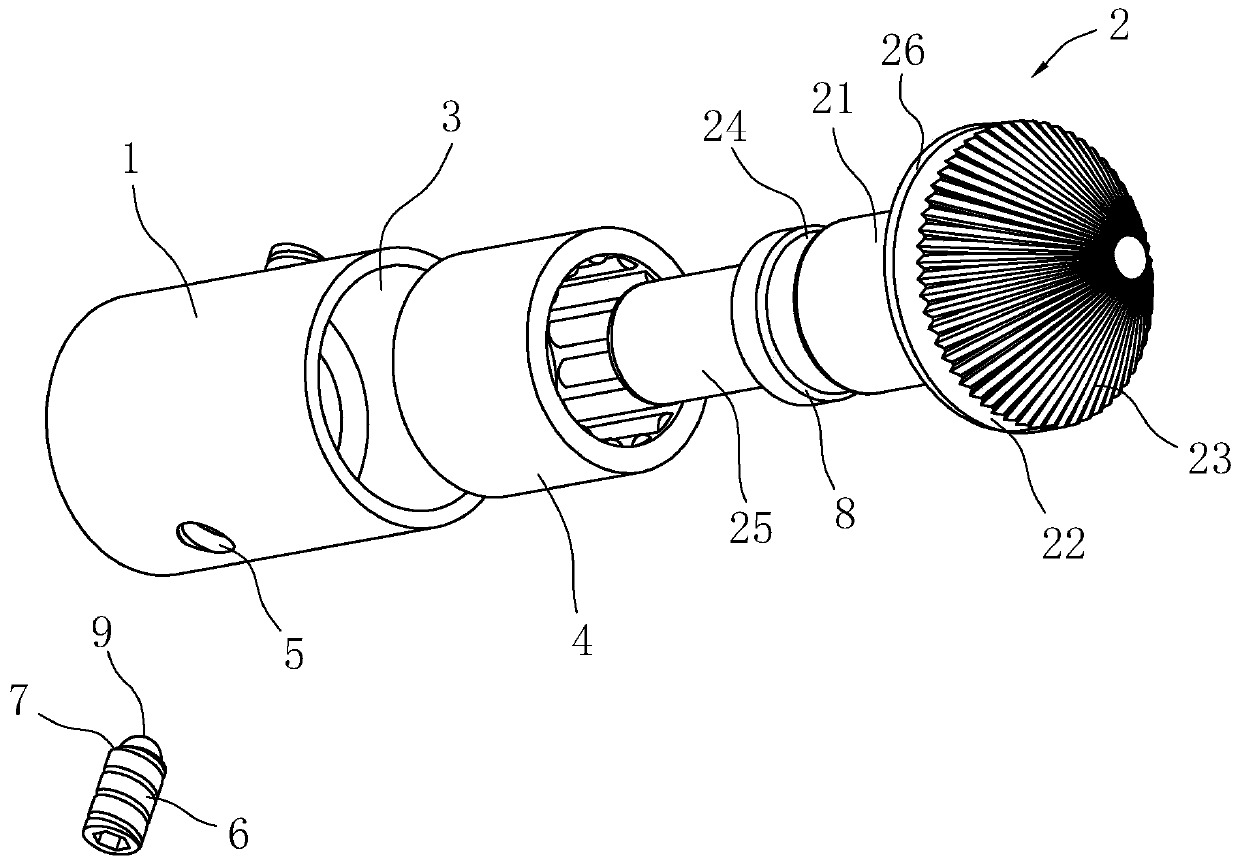

[0052] combine figure 1 and figure 2 As shown, a knurling cutter head mounting assembly includes a mounting head 1 and a knurling cutter head 2. A mounting hole 3 is opened on the mounting head 1, a needle bearing 4 is embedded in the mounting hole 3, and a needle bearing 4 is embedded in the mounting hole 3. There is a bearing hole, the bearing hole communicates with the mounting hole 3, the needle bearing 4 is embedded in the mounting hole 3 to be fixed, otherwise, the needle bearing 4 can be taken out from the mounting hole 3 by applying force to the needle bearing 4.

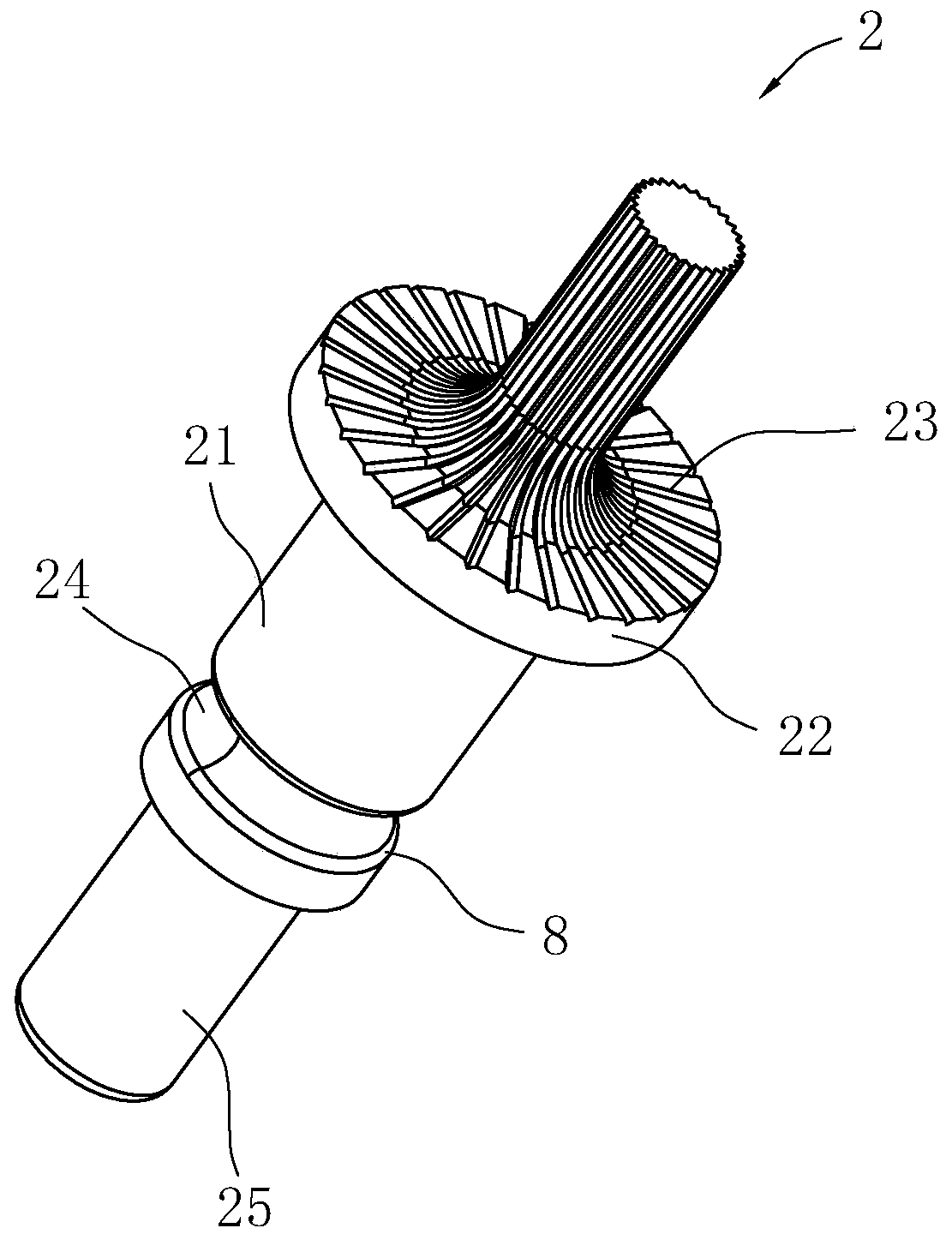

[0053] The knurled cutter head 2 includes a mounting column 21 and a knurled head 22 integrally formed on the mounting column 21. A knurled portion 23 is formed on the knurled head 22. The mounting column 21 is inserted into the bearing hole of the needle roller bearing 4. The column 21 is rotatable in the needle bearing 4 . Among them, the mounting column 21 is provided with an annular fastening groove 2...

Embodiment 2

[0062] combine Figure 7 and Figure 8 As shown, a straight tool includes a first handle 10 on which a knurled cutter head installation assembly is installed, and the knurled cutter head installation assembly is as described in the above technical solution.

[0063] The installation head 1 in the knurling cutter head installation assembly is integrally formed on the first handle 10, specifically, the installation head 1 is arranged in a cylindrical shape, and one end of the installation head 1 is integrally formed on the end of the first handle 10, and the installation hole 3 Opened at the other end of the installation head 1, the installation hole 3 and the installation head 1 are coaxially arranged. Thus, when the knurled cutter head 2 is installed in the installation hole 3 , the first handle 10 , the installation head 1 , the installation hole 3 and the knurled cutter head 2 are coaxially arranged.

[0064] It is worth noting that the first knife handle 10 is arranged in...

Embodiment 3

[0066] combine Figure 9 and Figure 10 As shown, a rotary tool includes a second handle 13, and the knurled cutter head installation assembly is rotatably installed in the rotation hole 15, and the knurled cutter head installation assembly is as described in the above technical solution.

[0067] The second handle of a knife 13 is arranged as a cuboid as a whole, and the end of the second handle of a knife 13 is provided with a turning groove 14, and the second handle of a knife 13 is provided with a turning hole 15 in the turning groove 14, and the turning hole 15 runs through the second handle of a knife 13, The knurled cutter head mounting assembly is fixed with a rotating shaft 16 on its mounting head 1, and the rotating shaft 16 is inserted into the rotating shaft 16 in the rotating hole 15, thereby realizing that the mounting head 1 is rotatably installed on the second handle 13 superior.

[0068] Wherein, the end of rotating shaft 16 is provided with mounting hole 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com