Variable-diameter spinning machine for ultra-long metal pipe material

A metal pipe and spinning machine technology, applied in the field of super-long metal pipe variable diameter spinning machines, can solve the problems of large radial runout and low quality of super-long metal pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

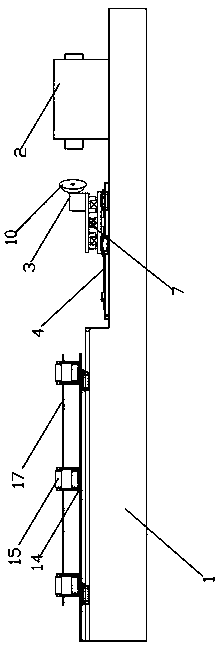

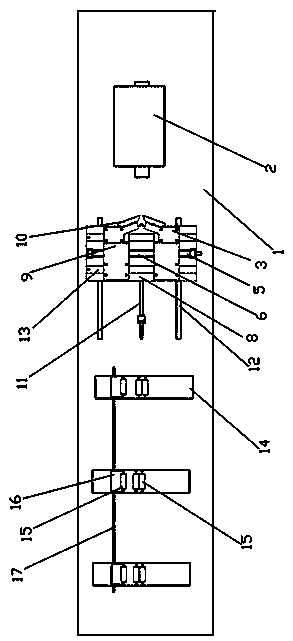

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0020] For specific implementation: see Figure 1 to Figure 2 , a variable diameter spinning machine for ultra-long metal pipes, comprising a base 1, a tail top assembly arranged at the tail end of the base 1, a spindle box 2 arranged at the head end of the base 1 and coaxial with the tail top assembly, The rotary wheel assembly 3, the transverse feed assembly 4 and the longitudinal feed assembly 5 are located on the base 1 and between the tail top assembly and the headstock 2. The headstock 2 is used to clamp the head end of the pipe and drive the pipe Rotate, the tail top assembly is used to support the tail end of the pipe, the longitudinal feed assembly 5 includes a first screw 6 driven by the first drive assembly to rotate, the two sides of the midpoint of the first screw 6 The direction of rotation of the screw thread is opposite, and the first screw n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com